Manufacturing process of dumbbell-shaped component with gradually-changed section height

A technology of section height and manufacturing process, applied in the field of manufacturing process of dumbbell-shaped components, can solve the problems such as the inability to guarantee the groove processing speed, the inability to use mechanical processing for the welding section, and the inability to guarantee the groove accuracy, etc., and achieves convenient and automatic processing. Easy to promote, easy to operate in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

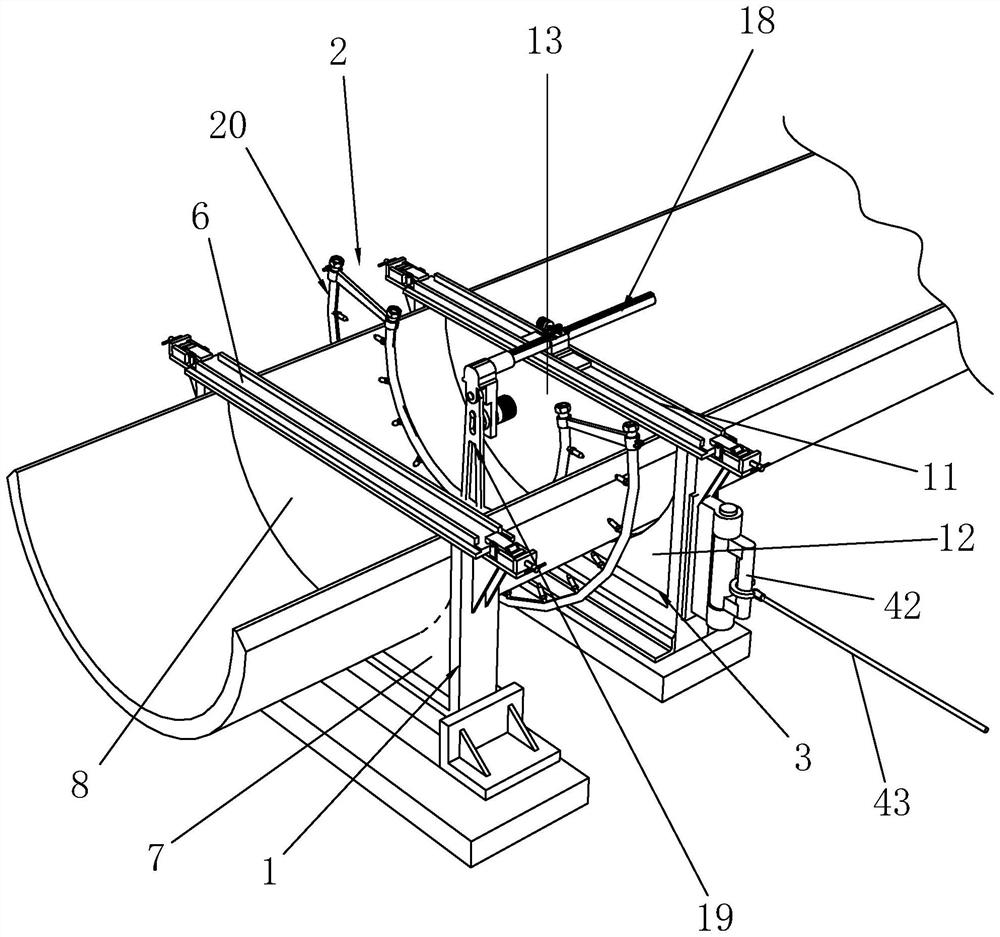

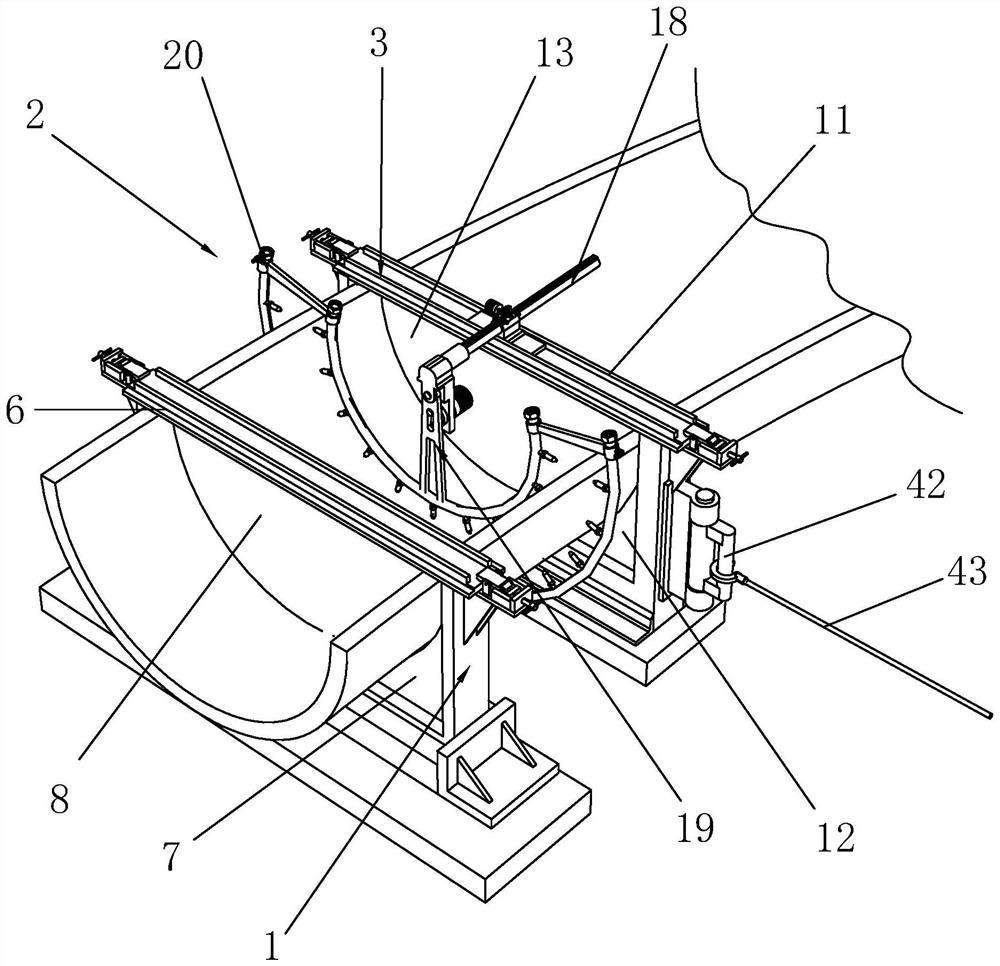

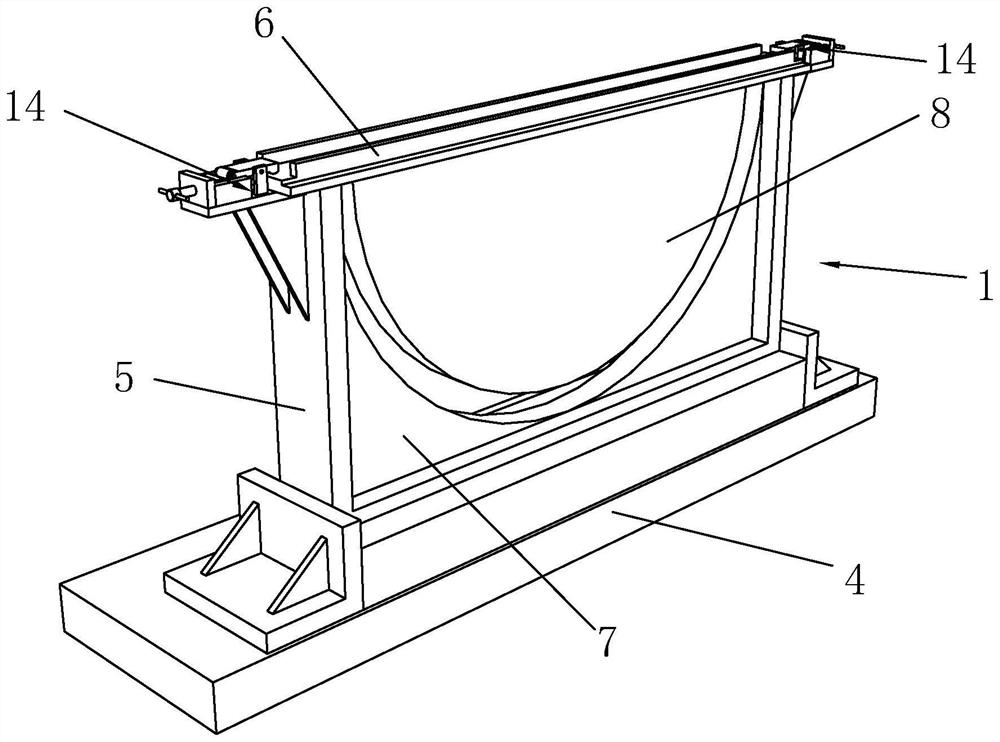

[0054] like Figure 1 to Figure 11 As shown, it is a manufacturing process of a dumbbell-shaped member with a gradual change in section height of the present invention, comprising the following steps:

[0055] A manufacturing process for a dumbbell-shaped component with a gradual change in section height, comprising the following steps:

[0056] (1) Processing of arc semi-circular tubes:

[0057] a. Process a straight round tube according to the design size, cut the straight round tube in half to obtain a straight half round tube, and mechanically cut the welding groove on the straight half round tube by cutting equipment; directly cut the straight round tube in half to obtain a straight half round tube. Semi-circular pipe, and mechanically cut the welding groove on the straight semi-circular pipe, which can effectively ensure the precision of the cut groove, and the use of mechanical cutting processing can ensure cutting efficiency and cutting quality, reduce labor intensity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com