Water treatment method

A water treatment and outlet pipe technology, applied in the field of water treatment, can solve the problems of inability to refine sewage or water purification treatment, inconvenient movement, high labor cost, etc., and achieve the effect of ingenious design concept, convenient later maintenance, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

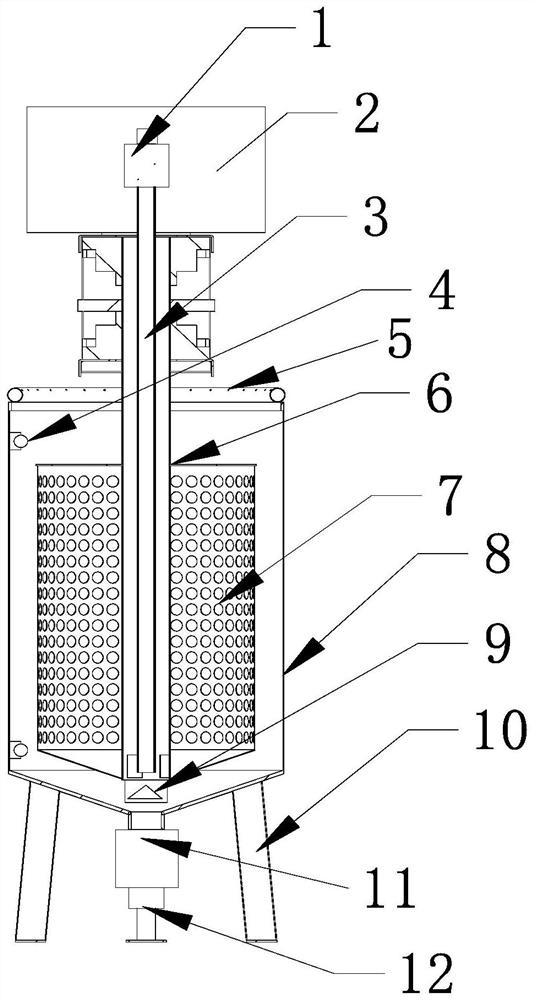

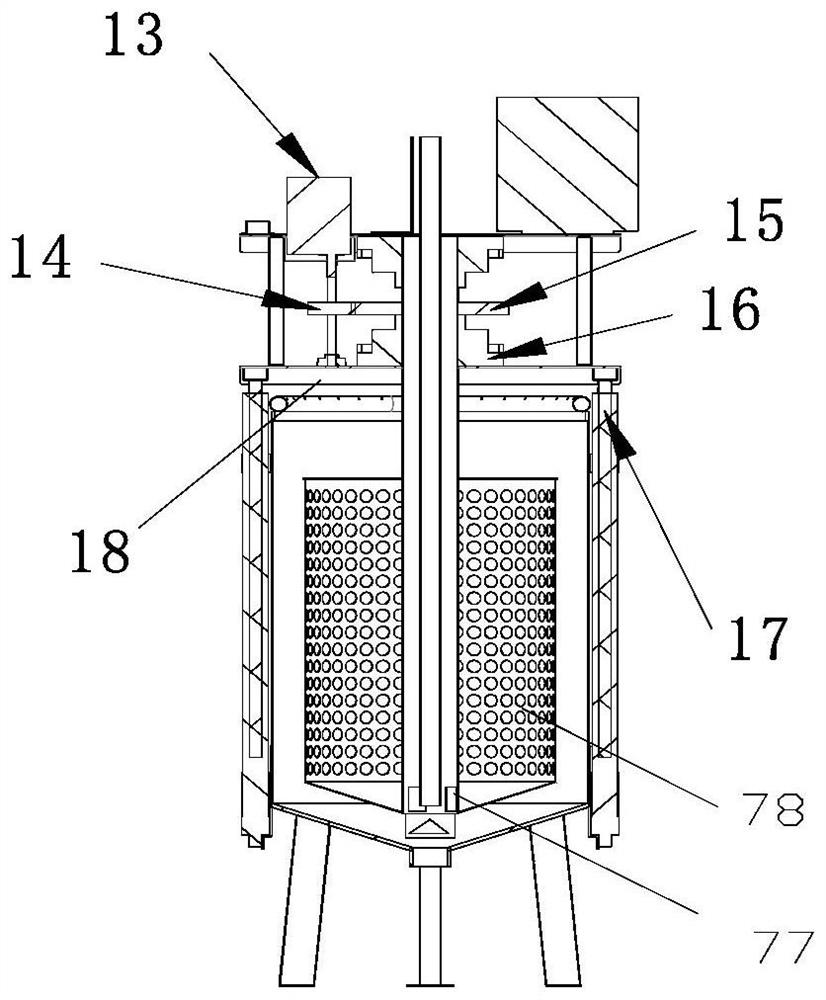

[0085] Example 1: Smart water treatment scheme with rotating filter element (preferred scheme)

[0086] (1) Intelligent water treatment device with rotating filter element

[0087] like Figure 1-4 , an intelligent water treatment device with a rotating filter element, including a container (specifically, an outer barrel 8, and the container can also be a sedimentation tank. At this time, there is no need for feet at the bottom of the sedimentation tank, and the bottom of the sedimentation tank can be connected to a discharge mechanism), a filter element 7. The filter element lifting mechanism, the liquid inlet pipe (5), the dosing mechanism, the liquid pumping mechanism and the discharging mechanism;

[0088] The filter element is placed in the container; the barrel wall of the filter element is provided with a plurality of filter holes;

[0089] The filter element is a rotary filter element; the filter element lifting mechanism includes a lifting platform and an electronic...

Embodiment 2

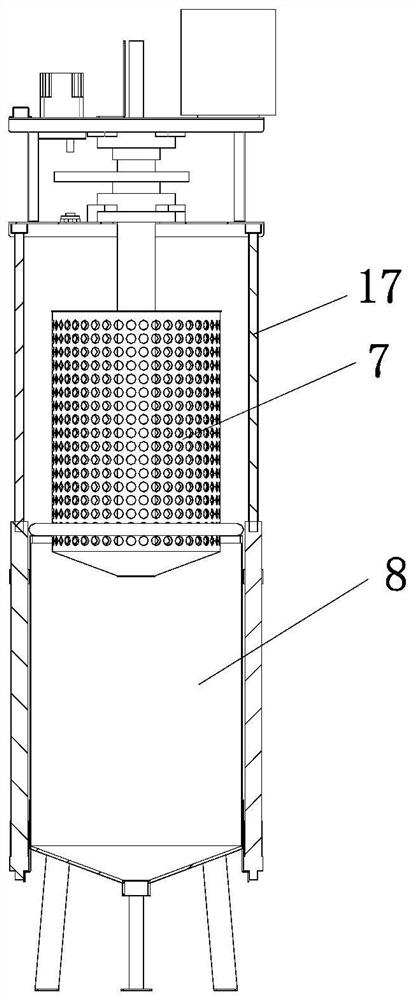

[0208] Example 2: Smart Water Treatment Scheme with Non-Rotating Filter Cartridges (Second-Optimal Scheme)

[0209] see Figure 18-20 , an intelligent water treatment device, including a container, a filter element 7, a filter element lifting mechanism, a liquid inlet pipe 5, a liquid pumping mechanism and a discharging mechanism;

[0210] The filter element is placed in the container; the filter element is a barrel-type device, and the barrel wall of the filter element is provided with a plurality of filter holes;

[0211] The filter element lifting mechanism includes a lifting platform and an electronically controlled lifting driving mechanism used to drive the lifting platform for lifting movement; the filter element is fixed on the lifting platform; looseness

[0212] The liquid inlet pipe is fixed in the container; the liquid inlet pipe is used to introduce the water to be purified and the water treatment agent into the container, and the water supply pipeline of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com