Rock breaking method, rock breaking device and tunneling device

A rock-breaking device and rock-breaking technology, applied in the field of rock-breaking devices, tunneling devices, and rock-breaking methods, can solve the problems of maximization, limited number of cutter heads, and not improving the cutting efficiency of a single cutter head, so as to avoid bearing bending moment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

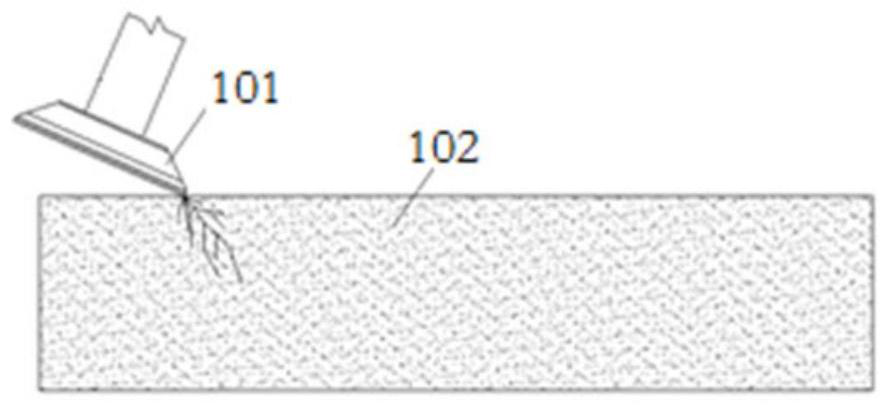

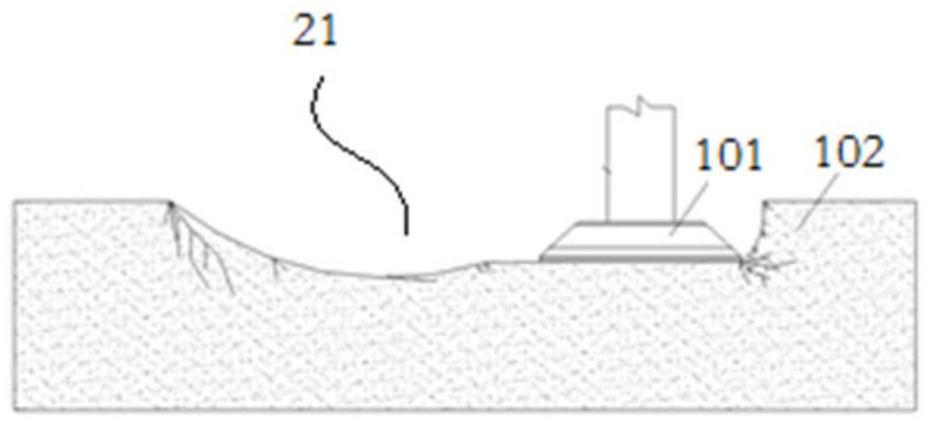

[0063] The rock breaking method includes the following steps: 1) use the hob 101 with its own hob drive device to beveled into the excavation surface 102 (such as figure 1 , Figure 4 ), and move the hob 101 along the set path until the cutting groove 21 that can be entered by the hob 101 as a whole (eg figure 2 , Figure 4 ); 2) Adjust the posture of the hob 101 so that the hob 101 and the excavation surface are substantially parallel (eg figure 2 ), move the hob 101 to make a flat cut towards the groove wall of the groove 21 until the excavation of the excavation surface is completed (eg Figure 5 , Figure 9 , Figure 10-Figure 15 ).

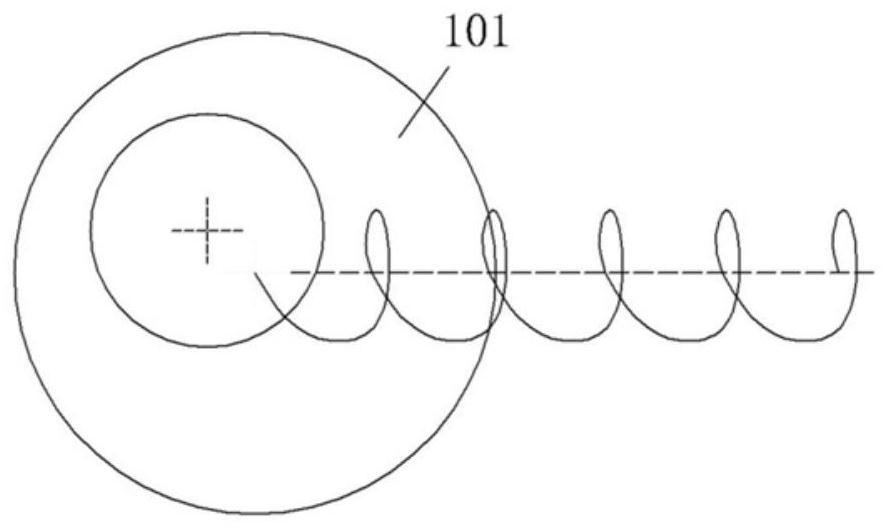

[0064] In this embodiment, the rotation axis of the hob 101 is eccentrically arranged to achieve the effect of vibrating rock breaking (such as image 3 ). In addition, in order to realize the adjustment of the inclination angle between the hob 101 and the excavation face, the hob 101 is mounted on a swing arm 103 (such as Image 6 ...

Embodiment 2

[0067] In Embodiment 1 of the rock breaking method of the present invention, the same hob 101 is used in step 1) and step 2). In this embodiment, the hob in step 2) can be a replaced hob For example, the roadheader has two cutting arms, the hob in step 1) is located on one of the cutting arms, and the hob in step 2) is located on the other cutting arm.

Embodiment 3

[0069] In Embodiments 1 and 2 of the rock breaking method of the present invention, one hob 101 is used to excavate the excavation face. In this embodiment, three hob 101 are used to excavate at the same time, among which three The hob cutters are located at different positions on the excavation surface, for example, in the radial direction of the central spindle 105, and the distances between the hob cutters 101 and the central spindle 105 are not equal. Of course, in other embodiments, the number of each hob may be two, or more than four, and the number of the hob may be selected according to specific conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com