Turbine blade and aero-engine

A technology of turbine blades and blades, which is applied in the direction of engine components, machines/engines, blade support components, etc., can solve problems such as vibration, and achieve the effects of simple process, energy reduction and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

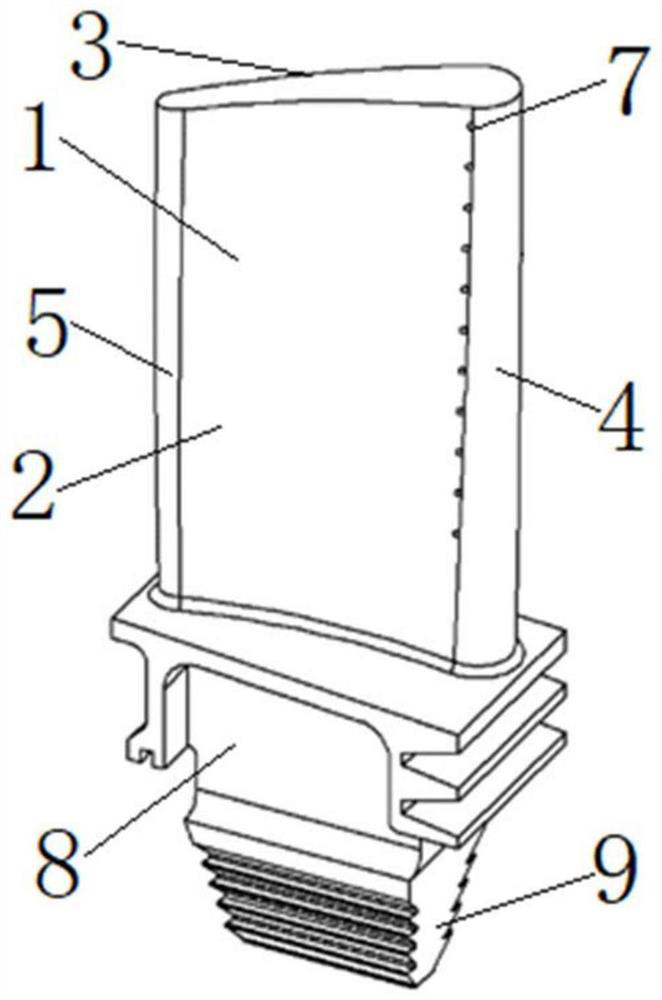

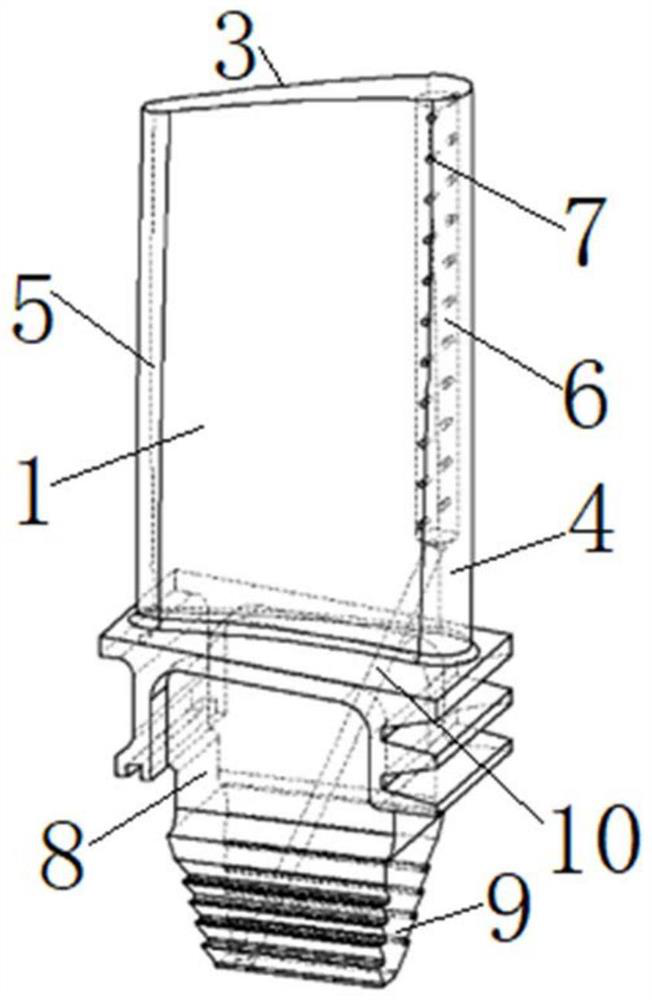

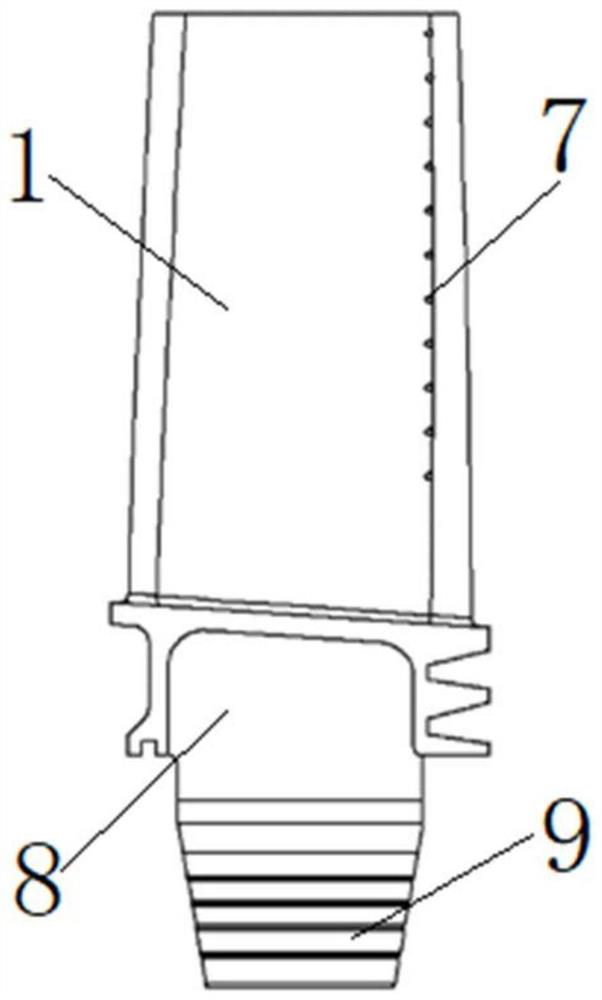

[0039] as attached Figure 1-5 As shown, Embodiment 1 provides a turbine blade, including a blade body 1 and a blade root 8; the blade body 1 has a preset twist angle, and the whole of the blade body 1 is a center-symmetric structure; The preset torsion angle is 20°; the blade body 1 is fixedly arranged at one end of the blade root 8, and the other end of the blade root 8 is used to be connected with the wheel disc; the blade body 1 includes the inner part of the blade Profile 2, blade back profile 3, blade inlet edge 4 and blade outlet side 5; the blade inner profile 2, blade back profile 3, blade inlet side 4 and blade outlet side 5 are enclosed to form the blade body 1.

[0040] The inside of the airfoil 1 is provided with a first cooling air passage 6, the first cooling air passage 6 extends along the length direction of the airfoil 1, and is arranged close to the air inlet edge 4 of the airfoil; A first air film hole 7 and a second air film hole are symmetrically arrang...

Embodiment 2

[0051] The structure and principle of a turbine blade provided in Embodiment 2 are basically the same as those of the turbine blade described in Embodiment 1, except that the special-shaped air film holes are the double-inclined round and right-angle air film holes.

[0052] as attached Figure 8 As shown, the double oblique circular right-angle air film hole includes a second oblique circular hole segment and a third oblique circular hole segment, and the inlet end of the second oblique circular hole segment is communicated with the first cooling air passage 6, The outlet end of the second oblique circular hole segment is connected with the inlet end of the third oblique circular hole segment, and the outlet end of the third oblique circular hole segment is connected to the surface of the blade inner profile 2 or the blade. The surfaces of the back mold surface 3 communicate with each other.

[0053] In this embodiment 2, the included angle between the hole axis of the secon...

Embodiment 3

[0057] The structure and principle of a turbine blade provided in Embodiment 3 are basically the same as those of the turbine blade described in Embodiment 1, except that the special-shaped air film holes are double-inclined circular V-shaped air film holes.

[0058] as attached Figure 9 As shown, the double oblique circular V-shaped air film hole includes a fourth oblique circular hole segment and a fifth oblique circular hole segment; the inlet end of the fourth oblique circular hole segment is communicated with the first cooling air passage 6 , the outlet end of the fourth oblique circular hole segment is connected to the inlet end of the fifth oblique circular hole segment, and the outlet end of the fifth oblique circular hole segment is connected to the surface of the blade inner profile 2 or the The surfaces of the blade back profile 3 are connected; wherein, the fourth oblique circular hole segment and the fifth oblique circular hole segment are located on the same tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com