Manufacture mehtod of elastic metal sheet for thin button

A technology of metal shrapnel and forming method, which is applied in the direction of electrical components, electrical switches, circuits, etc., to achieve the effect of reducing manufacturing cost, simple manufacturing process, and reducing mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

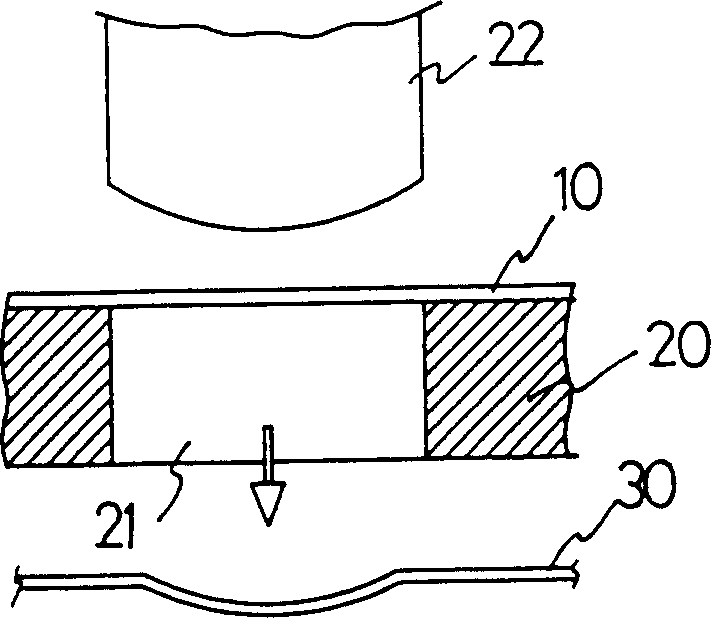

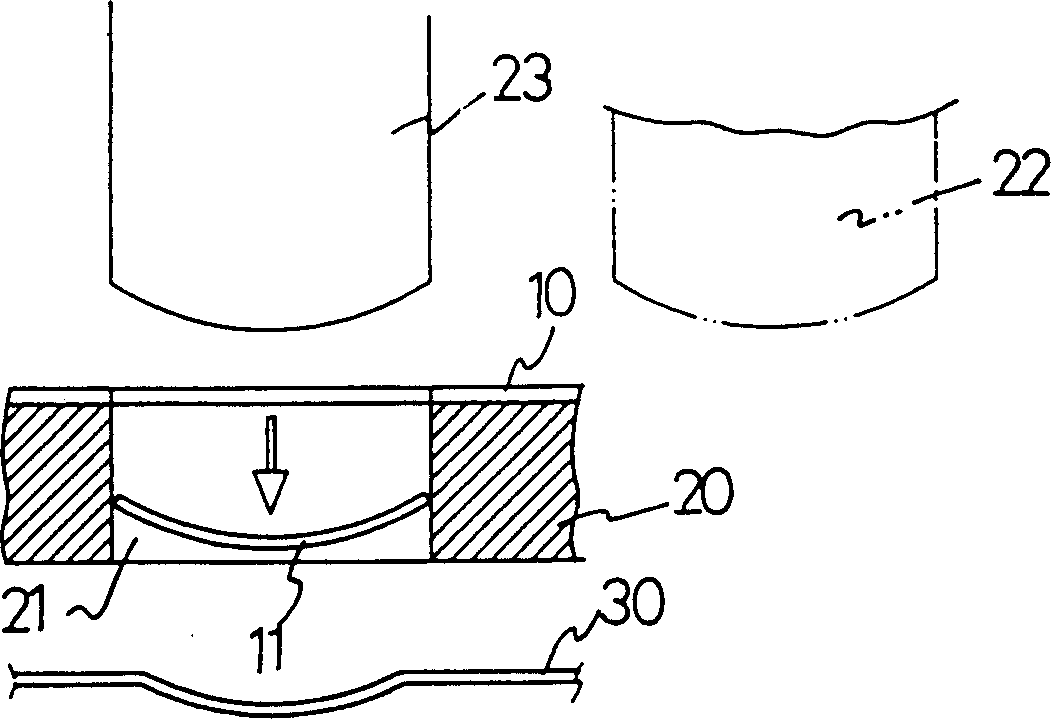

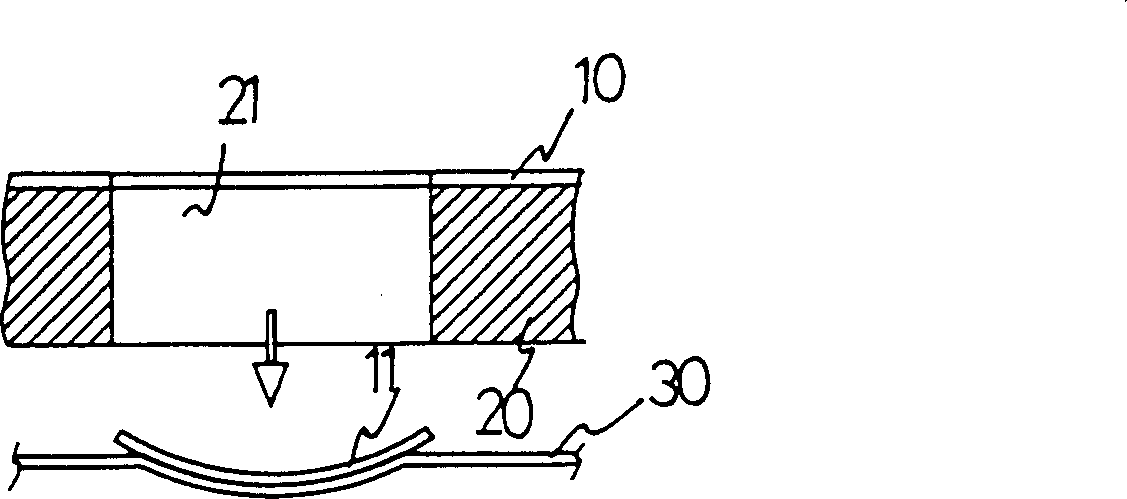

[0042] The specific method, structure, features and effects of the method for manufacturing and forming thin keypad metal elastic sheets according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0043] The method for manufacturing the metal elastic sheet of the thin keypad according to the present invention is mainly to form a plurality of mold cavities on the lower mold of the punch press, and each mold cavity is arranged according to the key contact position on the keypad circuit board, and an adhesive layer is provided under the lower mold , and when the shrapnel is punched out from the lower die of the punch press, the shrapnel is pushed out from the mold cavity through a push-out step, and at the same time pushed out to the surface of the adhesive layer, so that it is bonded to the surface of the adhesive layer, so that the same mold can be used in the In the same process, the punching of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com