High-rotating-speed long-shaft transmission vertical centrifugal pump unit and mounting method

A high-speed, centrifugal pump technology, applied in the field of centrifugal pumps, can solve the problems of troublesome transportation or cleaning of long-axis centrifugal pumps, inconvenient cleaning or maintenance of connecting pipes, etc., and achieve the effect of convenient transportation or cleaning and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Attached to the following Figure 1-6 This application will be described in further detail.

[0051] The embodiment of the present application discloses a high-speed long-shaft transmission vertical centrifugal pump unit.

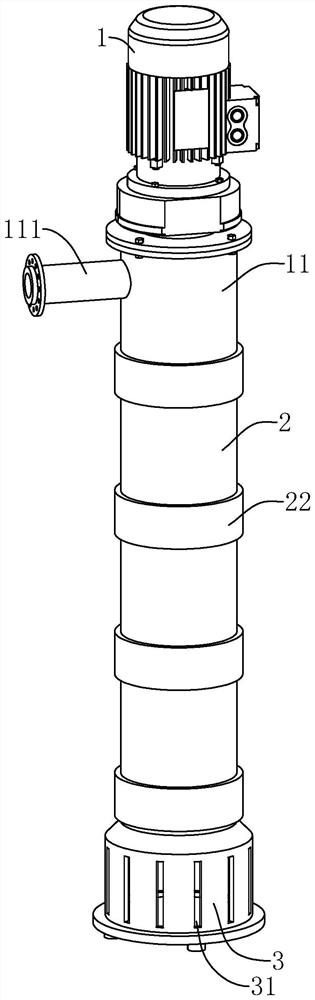

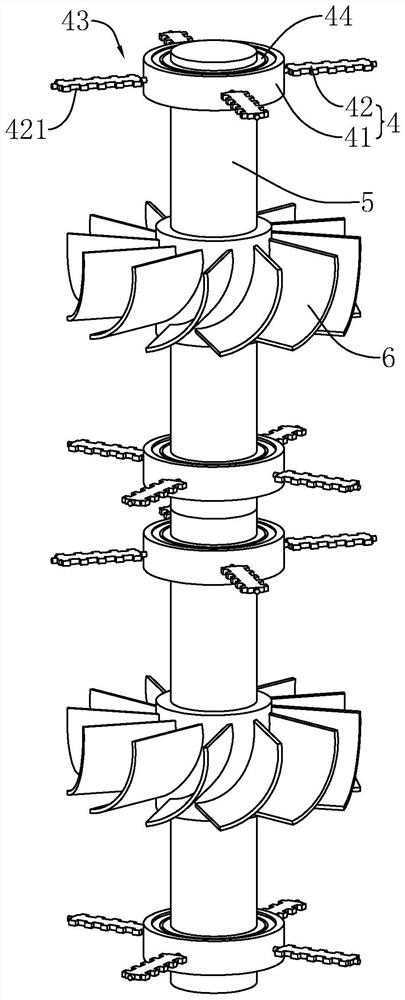

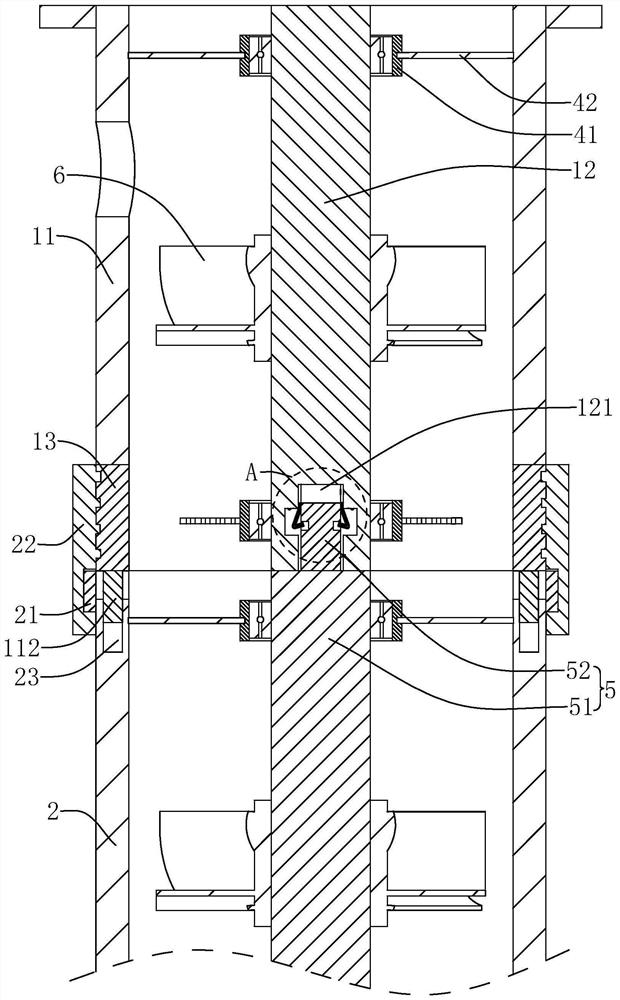

[0052] refer to figure 1 , the vertical centrifugal pump unit includes a motor 1, a conveying cylinder sleeved on the motor 1, the conveying cylinder includes a number of detachable connecting cylinders 2, the connection cylinder 2 away from the motor 1 is threadedly connected with a liquid inlet cover 3, several The connecting cylinders 2 are screwed and fixed to each other. The motor 1 is fixedly connected with a fixing cylinder 11 , the output shaft 12 of the motor 1 extends into the fixing cylinder 11 , and the connecting cylinder 2 close to the motor 1 is fixed to the fixing cylinder 11 through screw connection. The circumferential side wall of the liquid inlet cover 3 is provided with a number of liquid inlets 31, the circumferential side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com