Rock core drilling device for geological exploration

A technology for geological exploration and core drilling, which is applied in the field of core drilling devices, can solve the problems of incomplete cooling position of the drill bit, troublesome drilling rig fixing and moving, and shortening the life of the drill bit, etc., and achieves the effects of convenient splicing, rapid splicing and efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

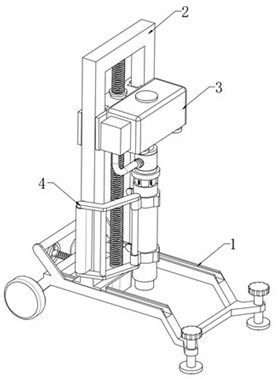

[0042] like Figure 1 to Figure 13 As shown, a core drilling device for geological exploration includes a support assembly 1, a lifting assembly 2, a drilling assembly 3 and an auxiliary assembly 4. The middle of the upper surface of the support assembly 1 is provided with a lifting assembly 2, which lifts the The assembly 2 is slidably connected with the support assembly 1 to adjust the position of the hoisting assembly 2 on the support assembly 1 according to usage requirements. One side of the lifting assembly 2 is provided with a drilling assembly 3, and the drilling assembly 3 can move up and down along the lifting assembly 2, so as to adjust the height of the drilling assembly 3 according to the usage requirements. The outer bottom end of the lifting assembly 2 is provided with an auxiliary assembly 4 .

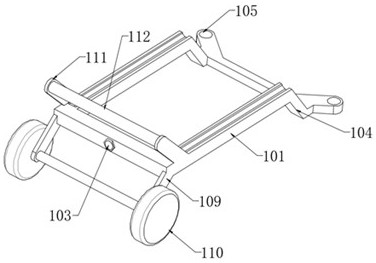

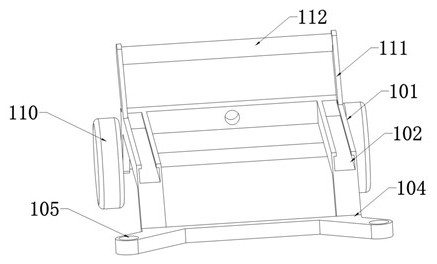

[0043] Support assembly 1, the support assembly 1 includes a support frame 101, the upper surface of the support frame 101 is provided with two symmetrically distribut...

no. 2 example

[0054] In the actual drilling work of cores, rock layers with different hardness are often drilled. When drilling hard rock formations, the high-speed rotating drill bit will heat up sharply. If the drill bit cannot be rapidly cooled by a large amount of drilling fluid, the life of the drill bit will be affected; while the traditional drilling device, after the drill bit drills the core, When the core enters the drill pipe, the supplied drilling fluid can only reach the drill bit through the small gap between the outer surface of the core and the inner wall of the drill pipe. As a result, the feeding amount of drilling fluid for cooling the drill bit is small, and the rapidly heated drill bit cannot be rapidly cooled in a timely and effective manner, which affects the life of the drill bit. Therefore, the structure of the drill pipe 320 is further improved to address the above problems.

[0055] like Figures 14 to 15 As shown, the inner wall of the drill pipe 320 is axially ...

no. 3 example

[0059] On the basis of the above embodiment, due to the improvement of the drilling fluid supply path, a large-flow liquid flow path can be formed to the drill bit through the liquid guiding groove 329, the guiding hole 330, and the limiting groove 326. When the drill bit 331 gets stuck in the core 332, the high-pressure pulsating water flow can be supplied through the booster pump 316, and the high-pressure pulsating water flow can pass through the liquid guide groove 329, the guide hole 330, and the limit groove 326 to the drill bit 331. The impact force is generated, and under the action of the reaction force of the impact force, a reverse driving force can be generated on the drill bit 331 and the drill pipe 320, which is conducive to the removal of the drill. Compared with the traditional core drilling device (the supplied drilling fluid can only reach the drill bit through the small gap between the outer surface of the core and the inner wall of the drill pipe, and cannot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com