Resonators for high power high temp. superconducting devices

A superconducting resonator, high temperature superconducting technology, applied in resonators, waveguide devices, electrical components and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

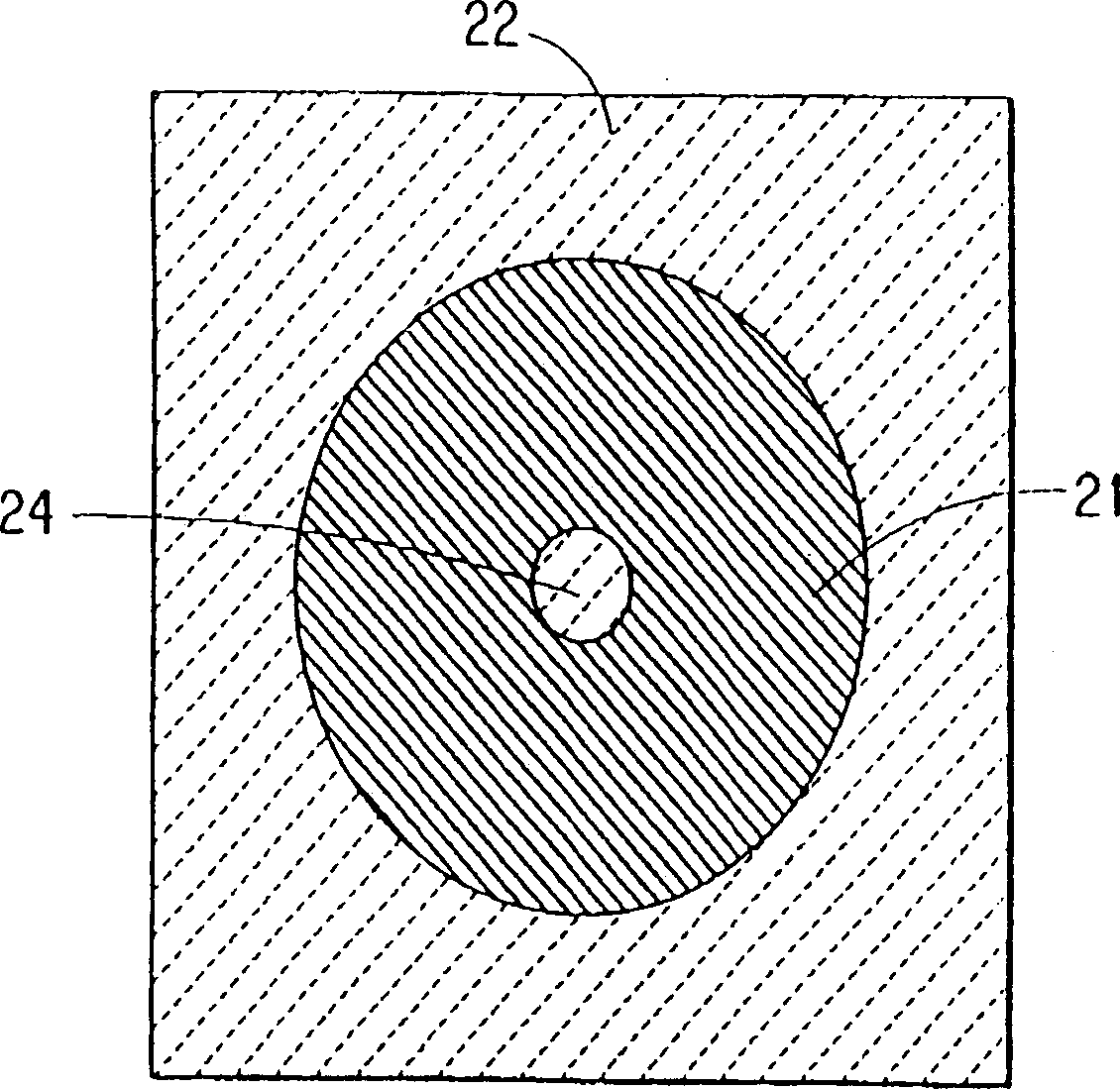

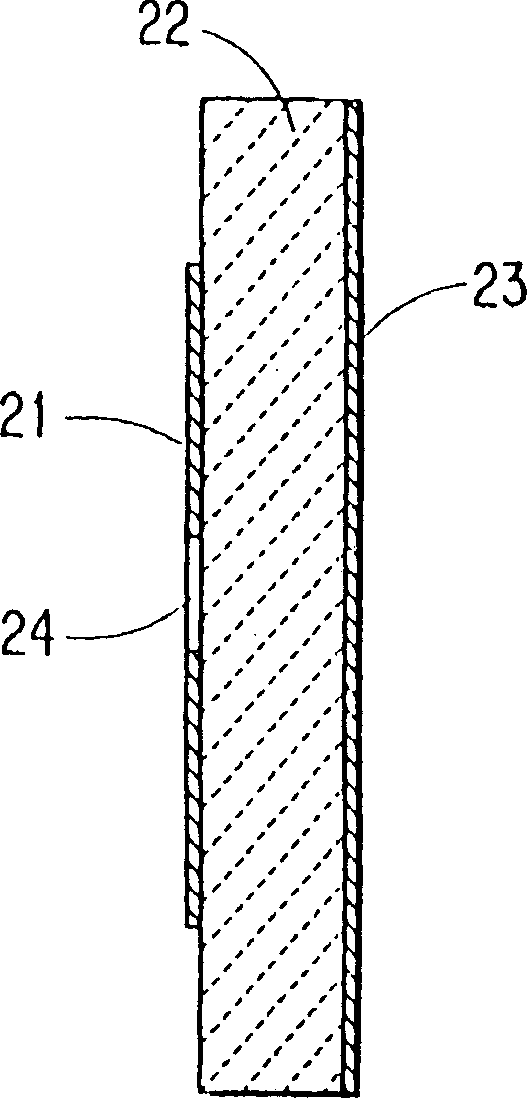

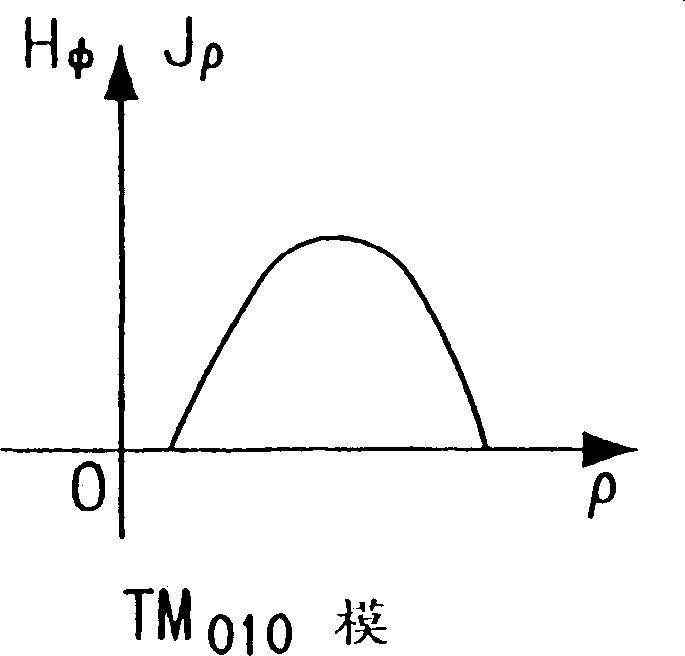

[0050] by LaAlO at 40.8mm x 17.2mm x 0.508mm 3 Deposit double-sided Tl on both sides (two levels) of the substrate 2 Ba 2 CaCu 2 o 8 HTS thin film, preparation of high power triode TM 010 modulo HTS filter. Using standard double-sided photolithography processing and ion beam milling, prepare filters with the structures shown in Figures 9(a) and 9(b), where 90 is a substrate; 91a and 91b are octagonal resonators; 92 is An octagonal resonator with a central hole 93 thereon; 94 is a ground plate; opening 95a, coplanar centerline 96a and T-shaped coupling branch 97a together form an input coupling circuit; opening 95b, coplanar centerline 96b Together with the T-shaped coupling branch line 97b, an output coupling circuit is formed; openings 98a and 98b form an internal resonator coupling circuit.

[0051] The filter was encased in a copper housing with SMA-compatible input and output connectors, and the filter was tested at 77K. The diameter of the central hole 93 in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com