Turbo-compressor device

A turbo compressor and internal space technology, applied in the direction of pump devices, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of expensive, complex components, high dissipation losses, etc., and achieve small supporting force , The effect of small rotor dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

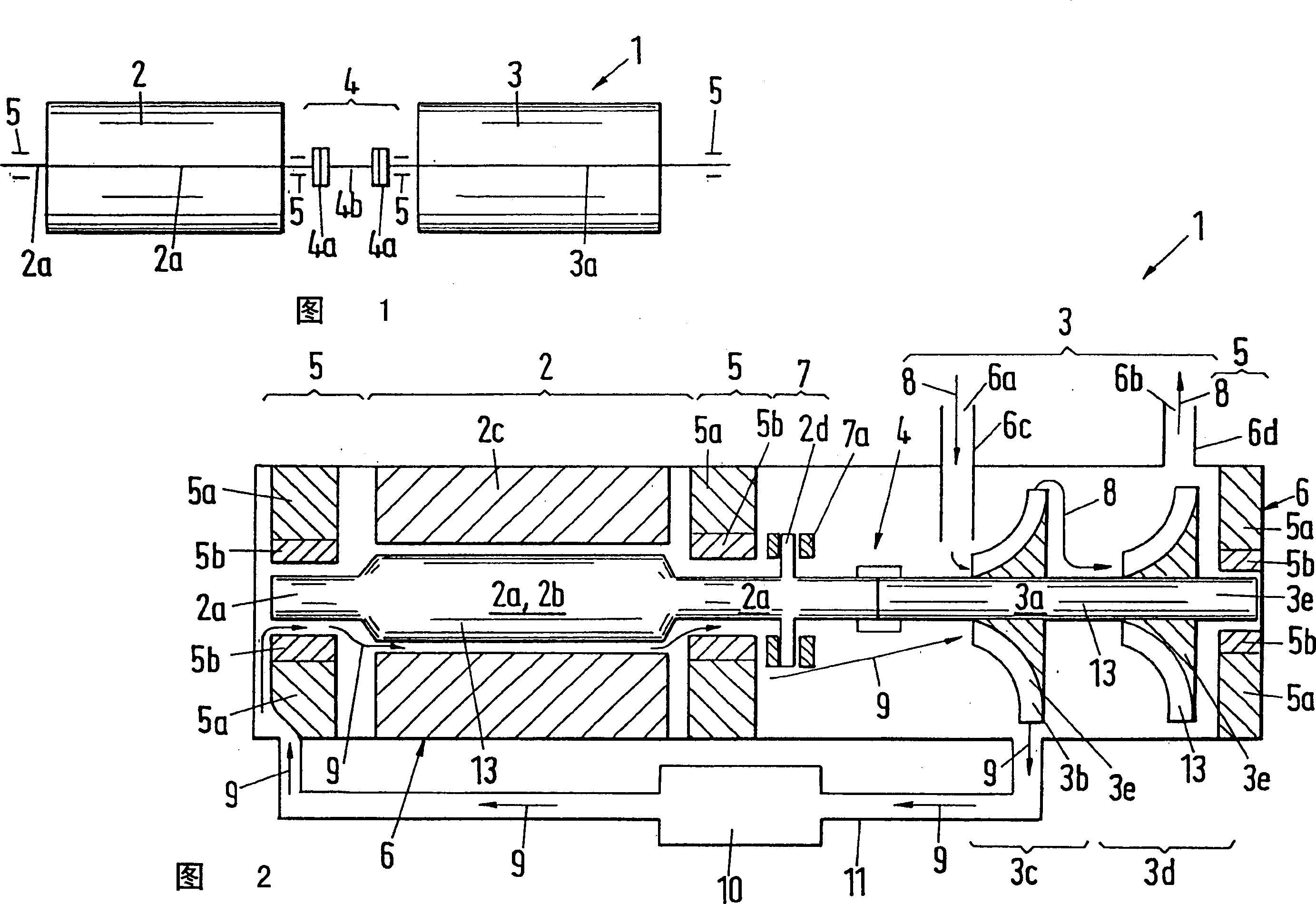

[0035] FIG. 1 schematically shows a known turbocompressor 1 comprising a radial turbocompressor 3 with a shaft 3a and a drive motor 2 with a shaft 2a. The shaft 3 a of the radial turbo compressor 3 is journalled at both ends by two radial bearings 5 . The shaft 3 a of the electric machine 2 is likewise journaled at both ends by two radial bearings 5 . The two shafts 2a and 3a are connected to each other through a connector 4, the connector 4 includes two connecting parts 4a and a flexible intermediate piece 4b, so that the motor 2 drives the radial turbo compressor 3 through the shaft 2a and the connector 4 Axis 3a.

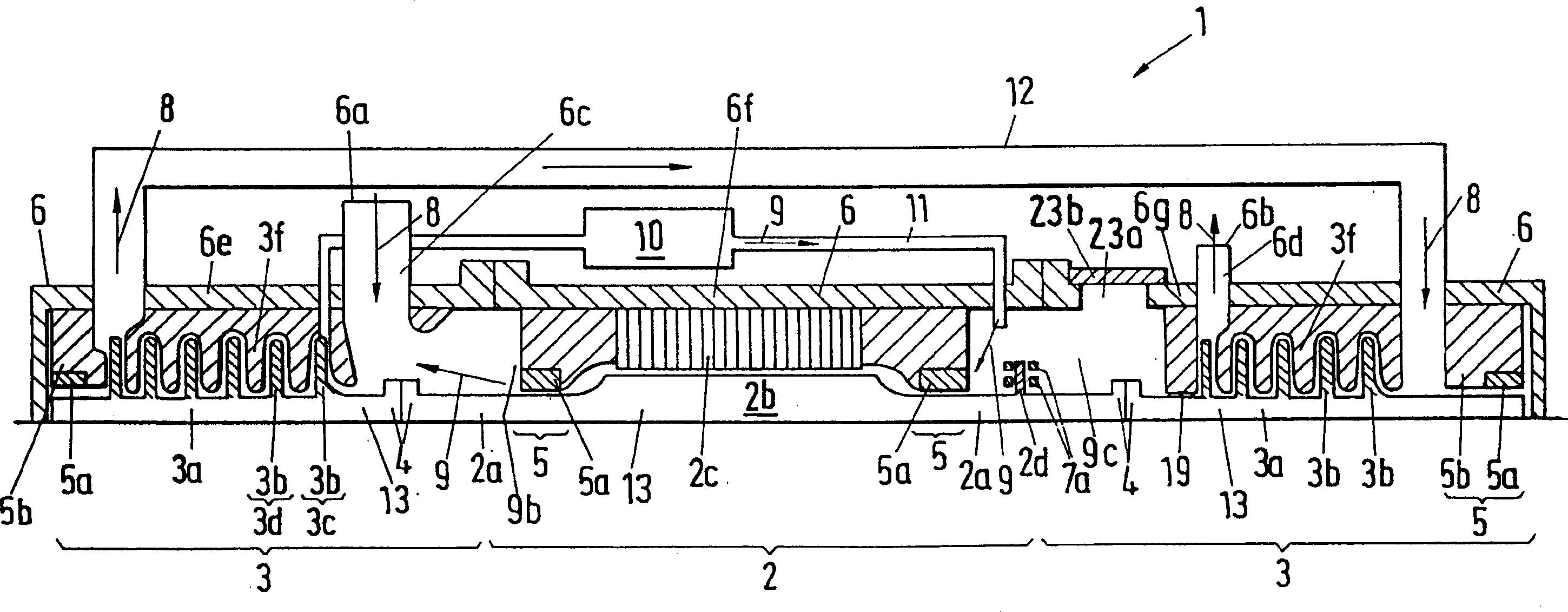

[0036] Fig. 2 shows a turbocompressor device 1, which is arranged in a sealed pressure-resistant casing 6, the pressure-resistant casing 6 is provided with an inlet pipe 6c and an outlet pipe 6b, both pipes lead into the pressure-resistant casing 6 , so that the radial turbocompressor 3 is fluidically connected to a device arranged outside the pressure-resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com