Bread maker with improved temperature and humidity control

A technology for making machines and bread, applied in baking, cooking utensils, household utensils, etc., can solve the problem of unsatisfactory bread texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

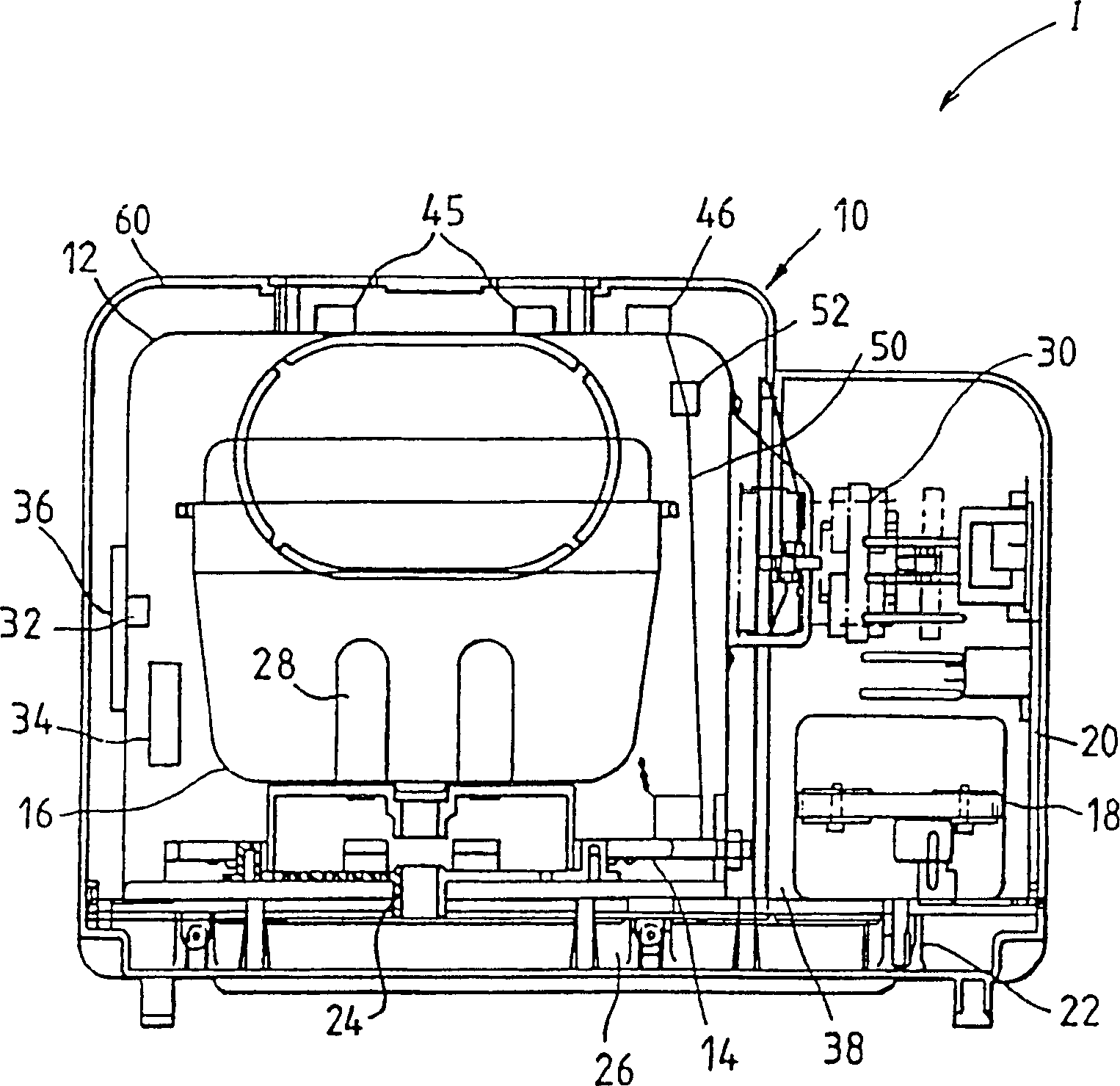

[0028] figure 1 A preferred embodiment of the manufacturing machine of the present invention is shown. The preferred bread maker of the present invention comprises a housing 10, a baking chamber 12, near the bottom of which baking chamber 12 is provided an electric heater 14 as a main heater, a baking pan 16, which is removably arranged In said baking chamber 12, to receive inside it the cooking ingredients (bread flour) for making bread, a stirrer motor 18, which is arranged in the motor chamber 20 adjacent to said baking chamber 12, but separated by a chamber wall It is removably separated from said baking chamber 12 by a baking chamber door 60 which allows bread flour to enter the baking chamber 12 .

[0029] The drive shaft 22 of the agitator motor 18 is connected to an agitator drive shaft 24 by a belt to transmit motion. In this manner, by driving the agitator motor 18 in a controlled manner, the agitator blade 28 connected to the agitator drive shaft 24 can be rotated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com