Regulating-control method for preparing different polymerization degree compound sugar by enzymatical method

A technology for enzymatic preparation and oligosaccharide, applied in the direction of oligosaccharide, can solve the problems of affecting large-scale production, complicated operation, serious pollution, etc., and achieve the effect of improving use efficiency, reducing pollution and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

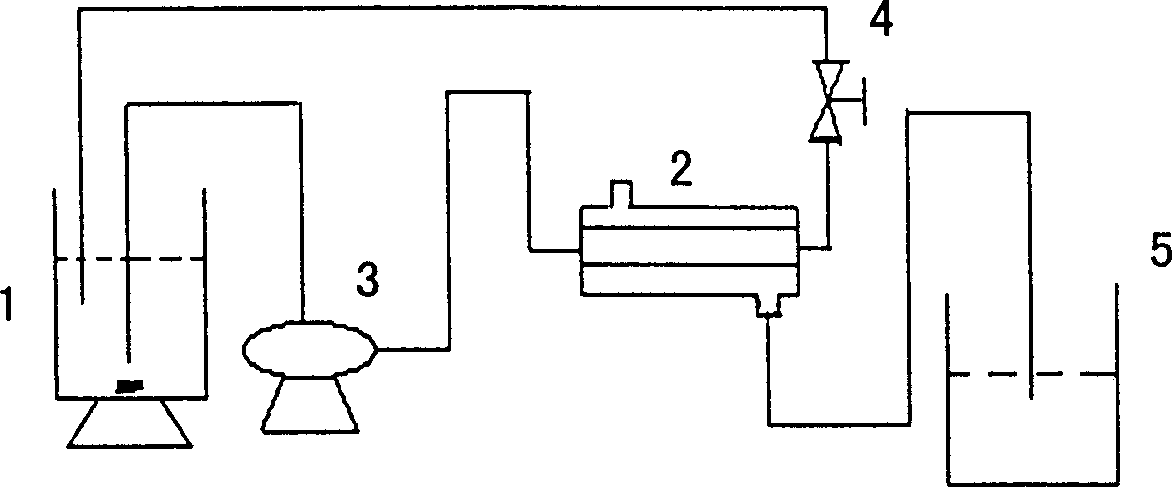

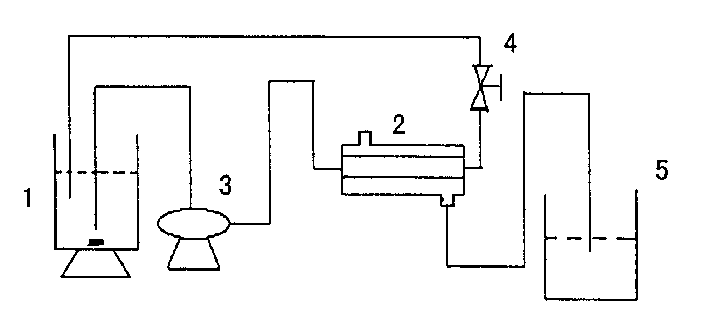

[0014] Embodiment 1: in enzyme degradation reactor 1, 0.5% chitosan is dissolved in pH5.6, concentration is in the sodium acetate buffer solution of 0.05M, filter and remove residue, add 1% chitosan enzyme to be degradation enzyme, react The temperature is 35° C., the reaction time is 4 hours, the chitosan is degraded, and the ultrafiltration can be performed after the viscosity of the solution drops to 40-60%. Hollow fiber membrane ultrafilter Roll-type flat membrane nanofilter is assembled into a membrane module 2 and connected to enzyme degradation reactor 1 through infusion pump 3 to separate oligosaccharides with different degrees of polymerization. The surface area of the hollow fiber ultrafiltration membrane is 2m 2 , the cut molecular weight is 2,000-10,000, the part smaller than the molecular weight cut off passes through the membrane to obtain ultrafiltrate, and the molecules larger than the molecular weight cut off return to the enzyme degradation reactor 1 throug...

Embodiment 2

[0015] Embodiment 2: 2% pectin is dissolved in the aqueous solution of 20L, add the pectinase of 3.0%, reaction temperature 50 ℃, reaction time 1 hour, pH3.0, flat membrane ultrafilter ultrafilter, adopt intermittent feed , the rest of the operations are the same as in Example 1 to obtain pectin oligosaccharides with a degree of polymerization of 3-20.

Embodiment 3

[0016] Example 3: 0.5% lipase was added to 3% carrageenan aqueous solution, the reaction temperature was 80° C., pH 10, and the rest of the operations were the same as in Example 1 to obtain carrageenan oligosaccharides with a degree of polymerization of 3-18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com