Alcohol preparing airlift fermentation and separation coupling technological process and special equipment

An air-lift fermentation and air-lift technology, which is applied in the field of ethanol preparation using air-lift fermentation separation coupling technology, can solve the problems of high cost, high energy consumption, and low utilization rate of raw materials, and achieve production cost reduction and recovery efficiency High, the effect of increasing the CO2 entrainment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

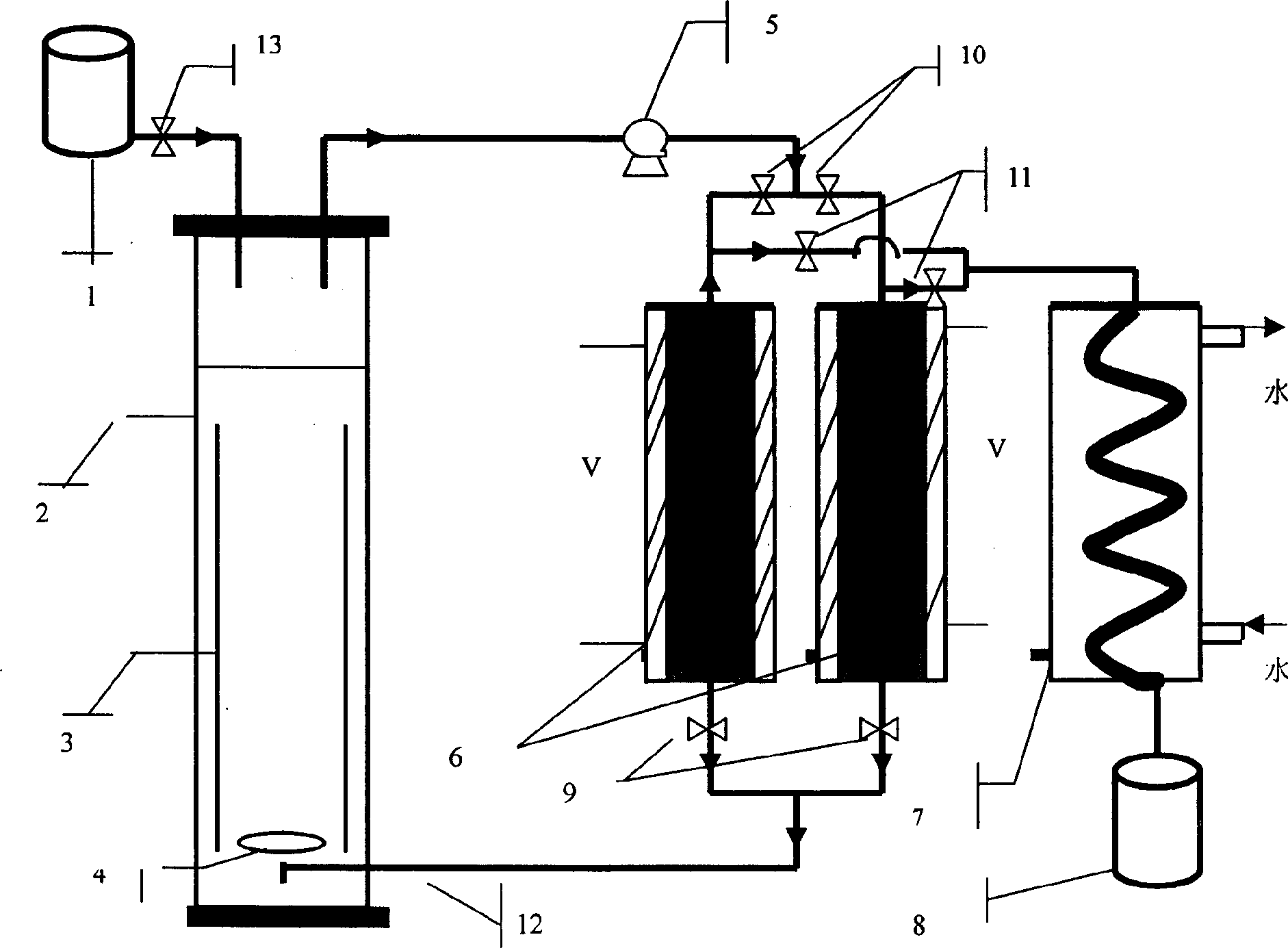

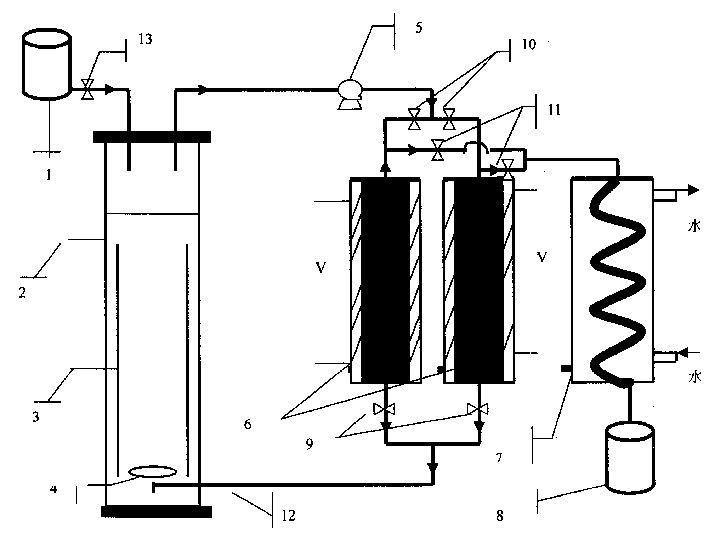

[0042] Embodiment 1. corn raw material saccharification filtrate fed-batch fermentation alcohol

[0043] Please refer to the attached figure 1 . The air-lift fermentation separation coupling equipment includes an air-lift alcohol fermentation reactor 2 with a sterile liquid storage tank 1, a water ring vacuum pump 5, an activated carbon adsorption tower 6 with an inlet and outlet, and an alcohol product collector 8 The condenser 7. The height-diameter ratio of the tank body of the air-lift alcohol fermentation reactor 2 is 8, and an internal circulation guide tube 3 with a height-diameter ratio of 7 is placed concentrically in the tank body of the air-lift alcohol fermentation reactor 2, and a gas distribution pipe 4 is placed at the bottom , the ratio of the diameter of the reactor 2 tank body to the internal circulation guide tube 3 is 0.6; the diameter ratio of the gas distribution pipe diameter to the reactor 2 tank body is 0.5, and the opening ratio of the small holes o...

Embodiment 2

[0048] Embodiment 2. corn thick mash batch fermentation alcohol

[0049] The equipment of Example 1 was utilized.

[0050] Carry out steaming, liquefaction and saccharification of corn grain raw materials (solid content is about 15%), filter and remove slag, and directly load into an air-lift bioreactor until the volume of the reactor is 60%; Raise the temperature to 120°C to sterilize the corn medium for 20 minutes, then cool the corn medium to 40°C, add 5% yeast seed liquid relative to the weight of the medium, and ferment at 35°C for 10-14 hours , when the alcohol concentration in the fermented liquid reaches 3wt%, open the water ring vacuum pump 5, and the water vapor and CO at the top of the air-lift alcohol bioreactor 2 The mixed gas with alcohol is pumped out to keep the vacuum at the top of the airlift bioreactor at 5000-8000Pa. The extracted mixed gas enters one of the two activated carbon adsorption towers 6 connected in parallel. When the alcohol sensor alarms, th...

Embodiment 3

[0052] Example 3. Fed-batch fermentation of alcohol with straw raw material hydrolyzate.

[0053] Equipment is with embodiment 1.

[0054] Put the glucose solution of the straw raw material through acid hydrolysis or enzyme hydrolysis into the air-lift bioreactor until it fills 70% of the reactor volume; raise the temperature to 120°C to sterilize the straw medium for 20 minutes, and then Cool the stalk culture medium to 40°C, ferment at 35°C for 10--12 hours, when the alcohol concentration in the fermented liquid reaches 3wt%, turn on the water ring vacuum pump 5, and remove the water vapor and CO from the top of the air-lift alcohol bioreactor. 2 The mixed gas with alcohol is pumped out to keep the vacuum at the top of the airlift bioreactor at 7000-8000Pa. The extracted mixed gas enters one of the two activated carbon adsorption towers 6 connected in parallel. When the alcohol sensor alarms, the activated carbon adsorption tower with saturated adsorption is switched to ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com