Procedure and apparatus for fabrication of blank for structural product, and blank for structural product

A technology of structural parts and blanks, applied in applications, household components, flat products, etc., can solve the problems of being unable to be dispersed and damaging the quality of the board, and achieve good dispersion and orientation, and improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

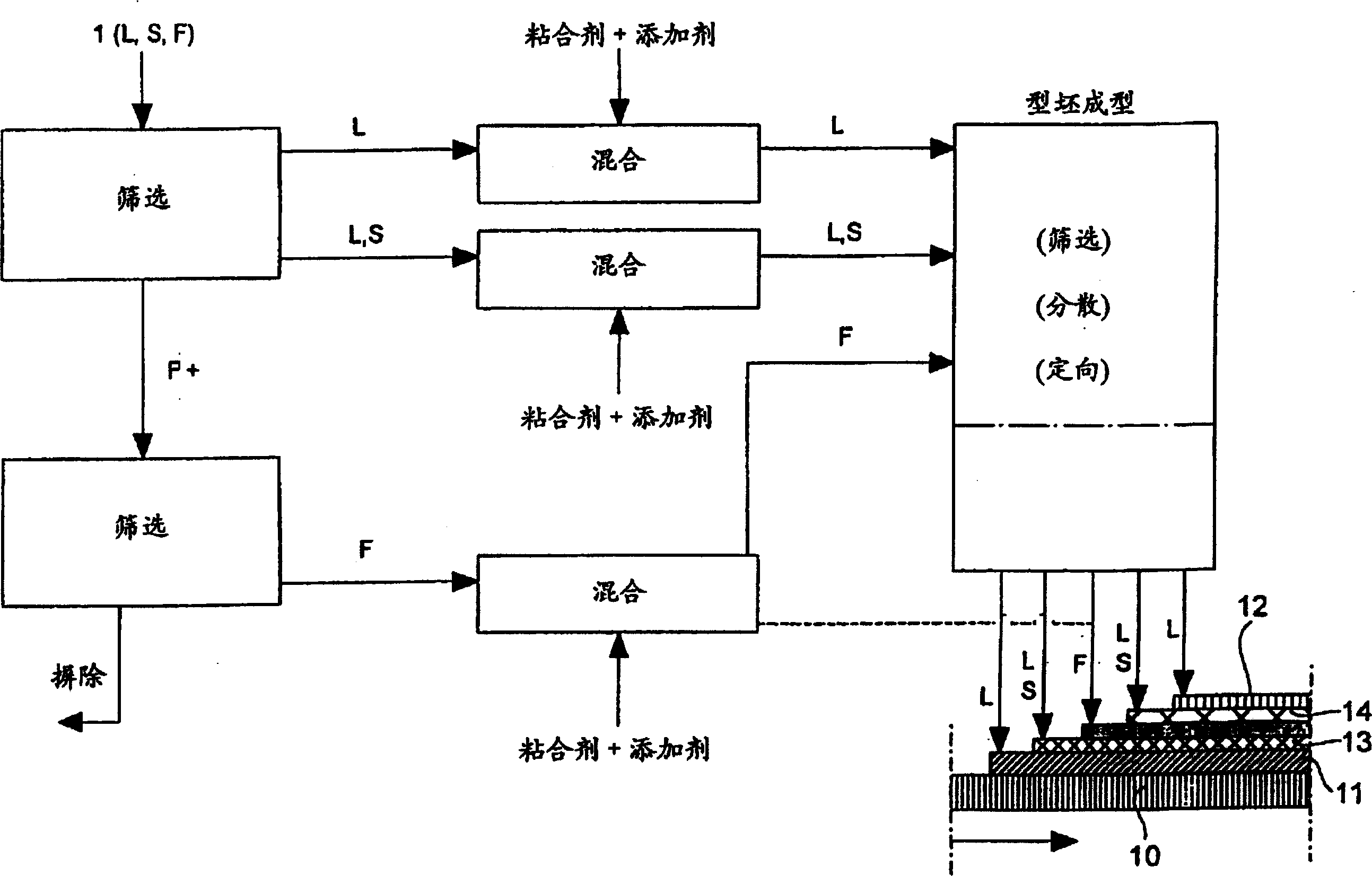

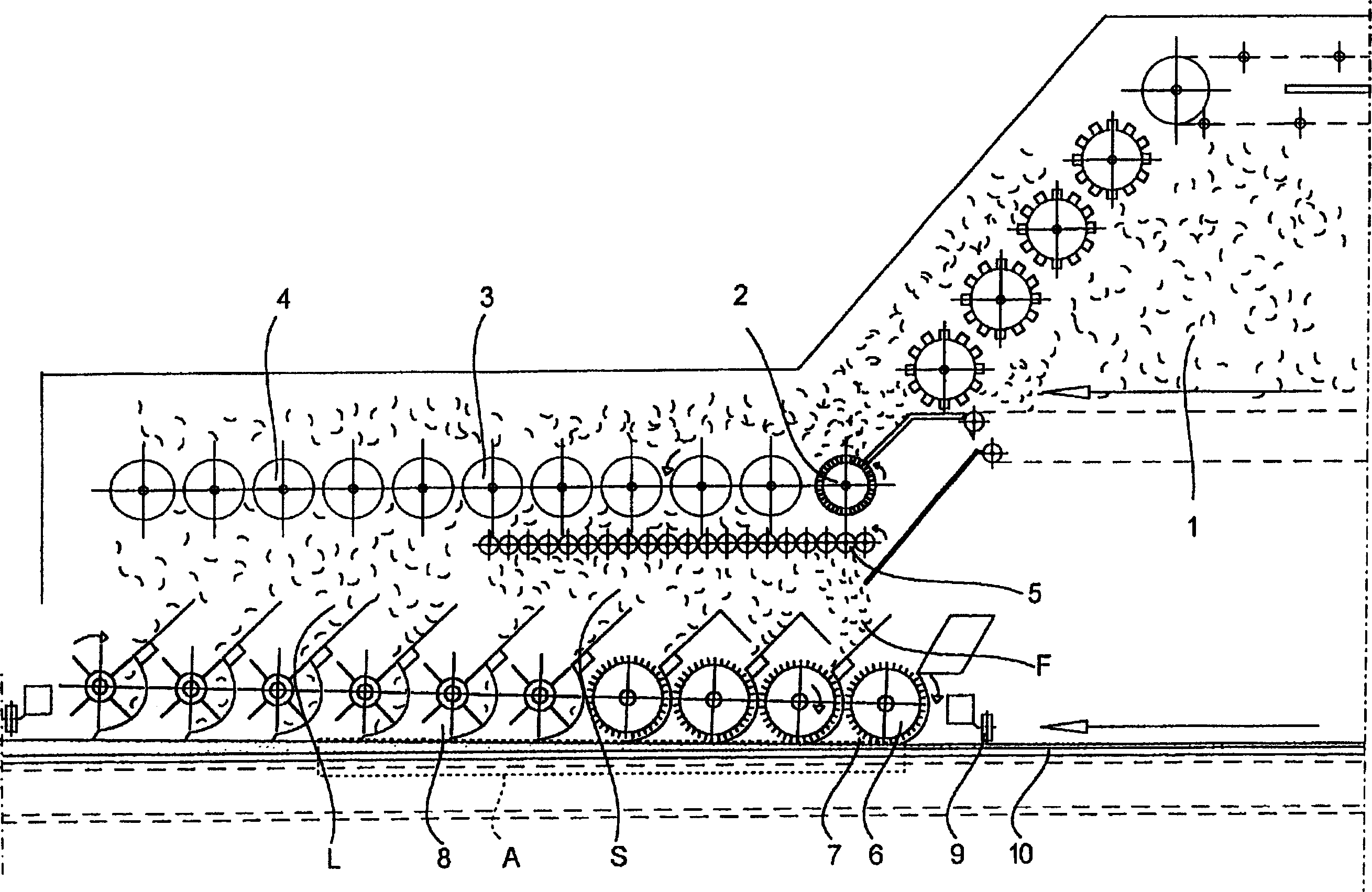

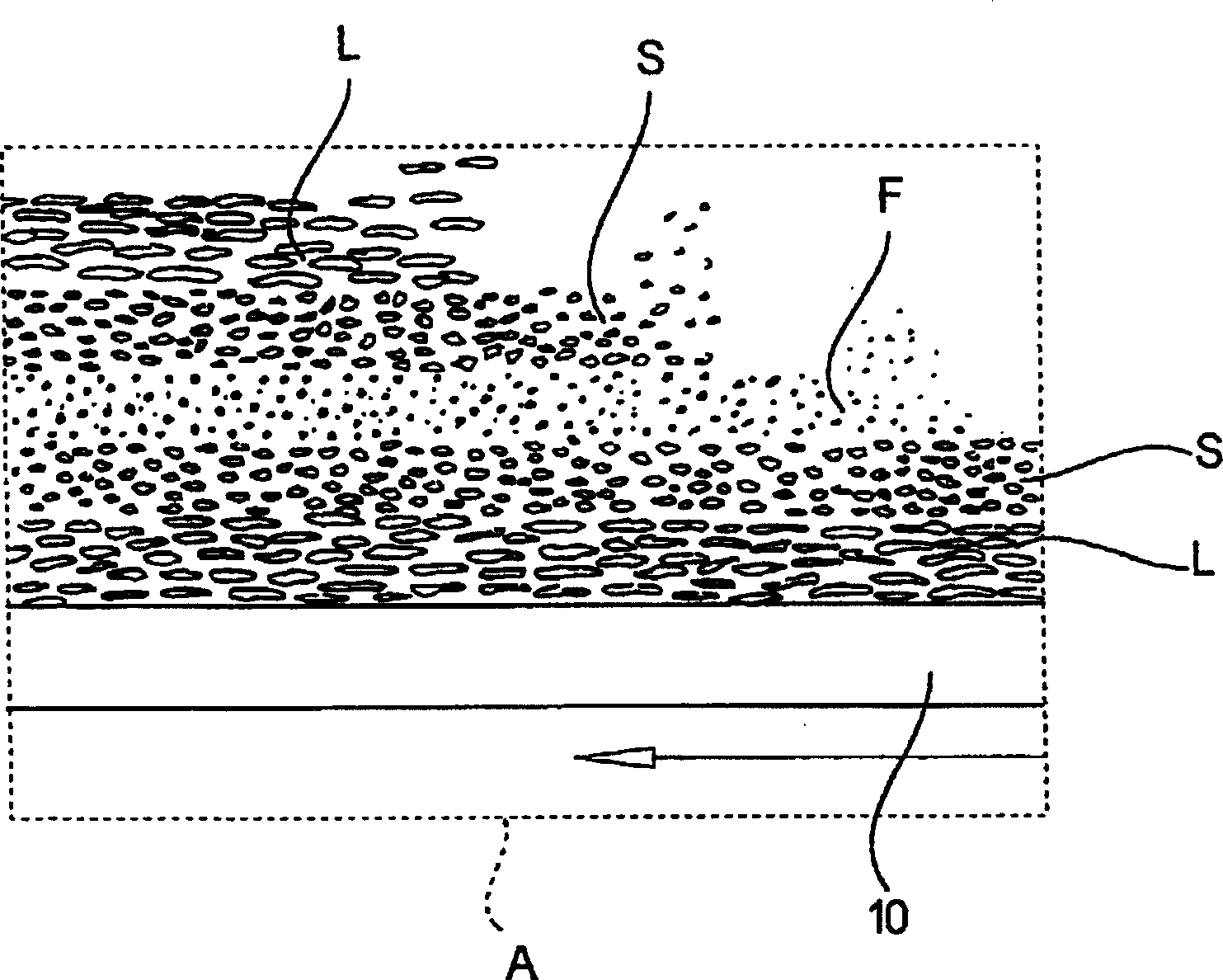

[0013] A method of manufacturing blanks for structural elements, such as blanks for structural panels, the raw material 1 of which blanks for structural elements comprises longer particles L and shorter particles S, such as long and short chips and / or fibers , may also comprise particles F smaller than them, in which process the particles are mixed with a binder and possibly additives and then conveyed to at least one blank-setting machine, whereby the particles are placed on a substrate 10, e.g. The belt conveyor is either the mold or the blank from the previous unit. At first, at least one surface layer 11 formed by long particles L is placed on the substrate 10, and smaller particles F are placed on these long particles to form one or more intermediate layers 13, 14. Longer particles L are again placed on the middle layer to form a second surface layer 12 . The shortest particles F are then placed on the substrate in such a way that they are distributed predominantly in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com