Ink pump of printer drived by movement of bracket

An ink pump and ink technology, which is applied to the components of pumping devices for elastic fluids, machines/engines, liquid fuel engines, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

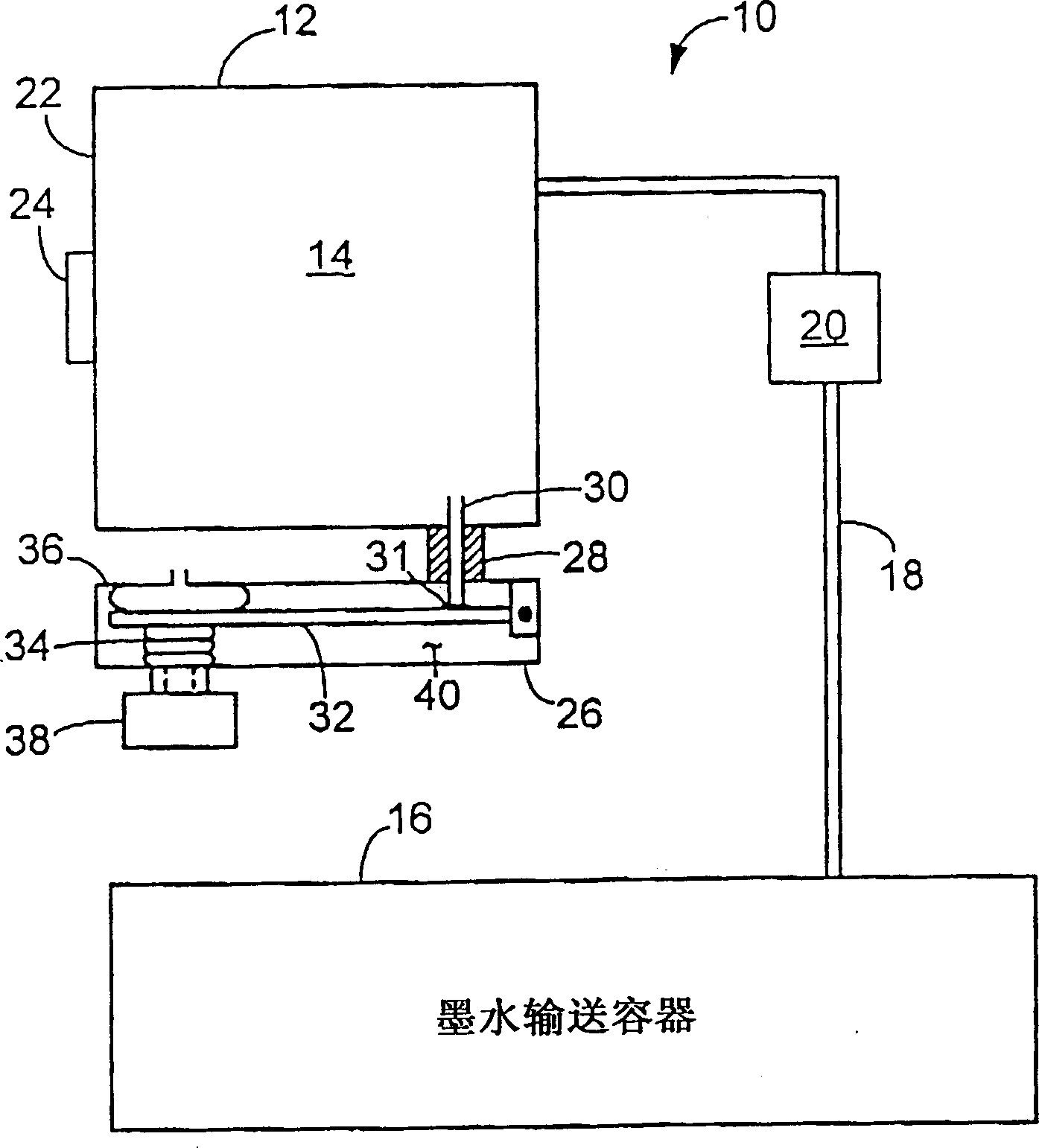

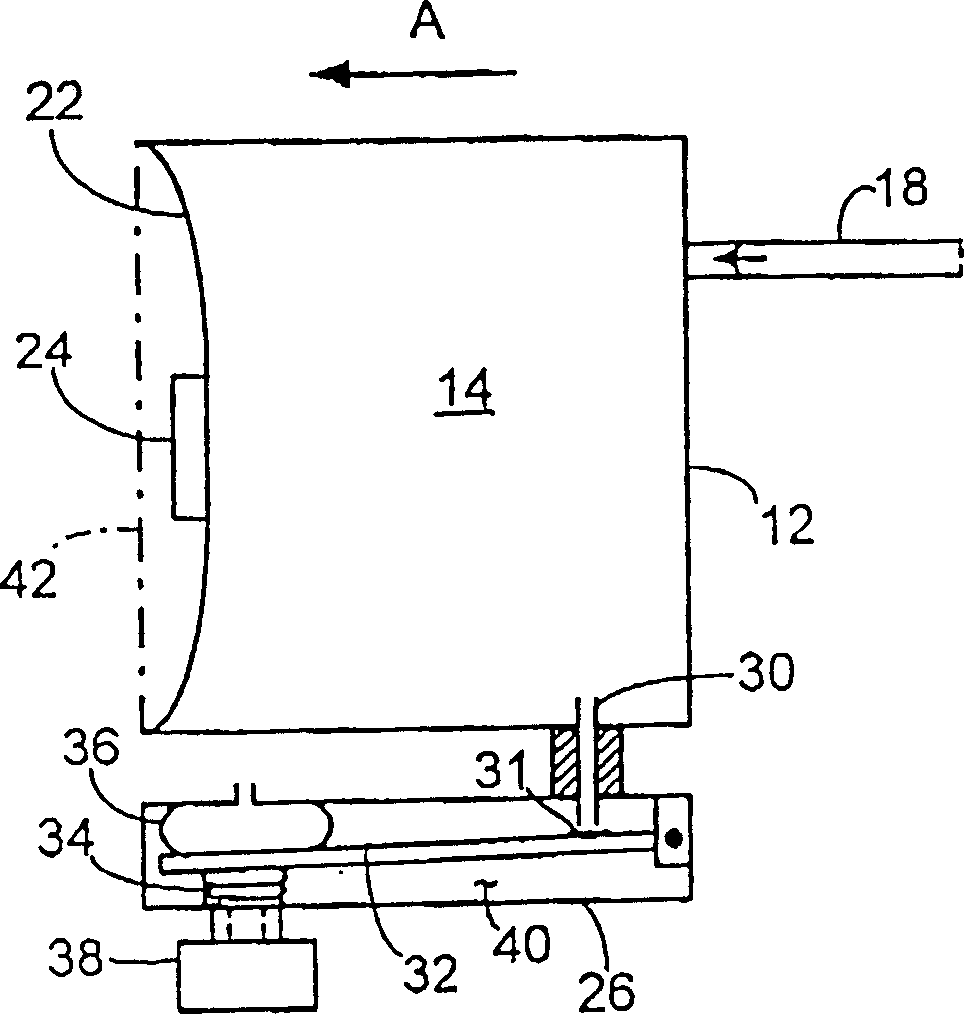

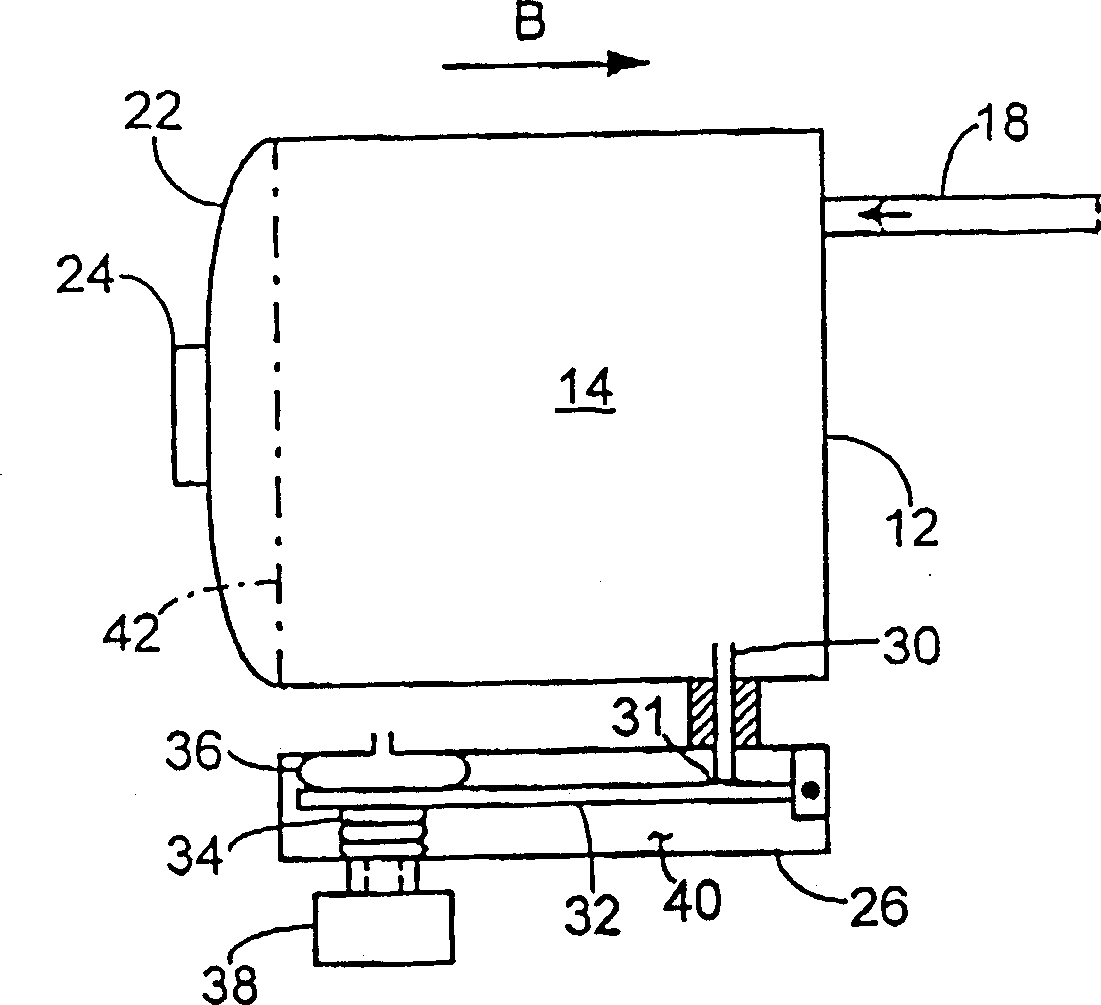

[0018] The same symbols in the various drawings represent the same components. With reference to the accompanying drawings, figure 1 Shown is an ink delivery system for a printhead 38 on a moving carriage, which includes an ink pump 12 on the moving carriage, wherein the ink pump 12 has a carriage container 14, the carriage container 14 is connected to an ink delivery container 16 by an ink delivery tube 18. The ink delivery tube 18 includes a one-way check valve 20 to control the flow of ink through the ink delivery tube 18 . It is preferred, but not necessary, to have a structure that includes the check valve 20 to regulate the flow of ink through the ink delivery tube 18 .

[0019] The carriage container 14 includes at least one flexible wall 22 which deforms due to the inertial resistance to the acceleration of the moving carriage and thus the ink pump 12 . The flexible wall 22 preferably has an integrated block such as a weight 24 to increase the inertial resistance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com