Elevator arrangement for setting starting toque of motor of elevator machinery

A technology of starting torque and fixing device, which is applied in the direction of lift, transportation and packaging, and measuring force components, etc. It can solve problems such as guide rail friction deviation and achieve the effect of short transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

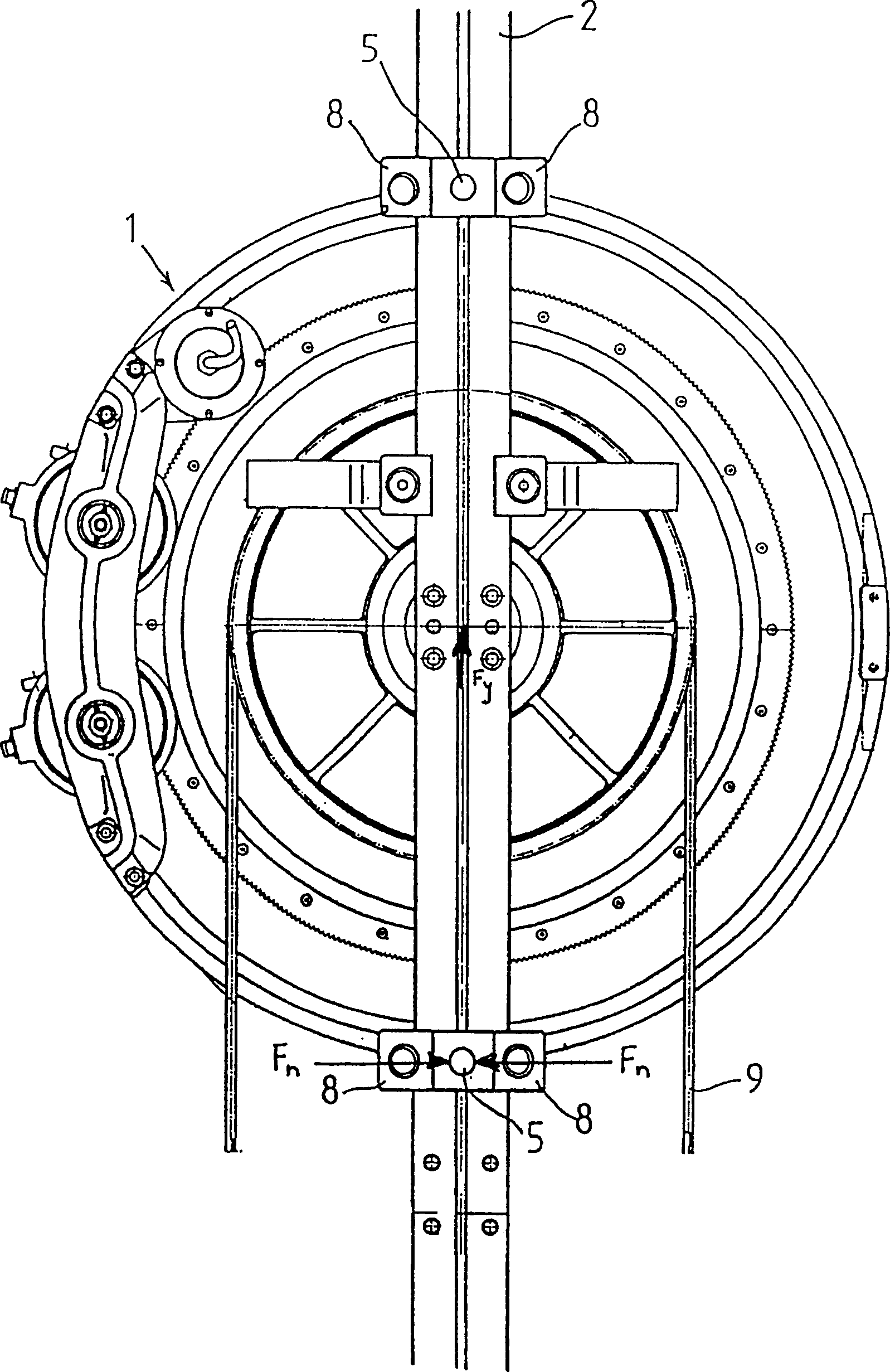

[0017] figure 1 An elevator arrangement according to the invention is shown in which an elevator machine 1 is fastened to a guide rail 2 in an elevator shaft by means of a guide rail fastening device 8 which fastens the elevator machine by means of its upper and lower parts. The dynamic sensor 5 according to the invention is arranged together with the guide rail fastening device 8 . When the load of the car changes, the magnitude and possibly the direction of the force acting on the rope 9 also changes. exist figure 1 In , the center of the elevator machinery is used as the first bearing point, which bears the vertical forces Fy and 2. The attachment point of the dynamic sensor 5 also serves as a load-carrying bracket, receiving the force Fn generated by the torque. The load acting via the rope thus produces a torque on the machine, and this torque, ie the unbalanced moment, is detected by the dynamic sensor 5 .

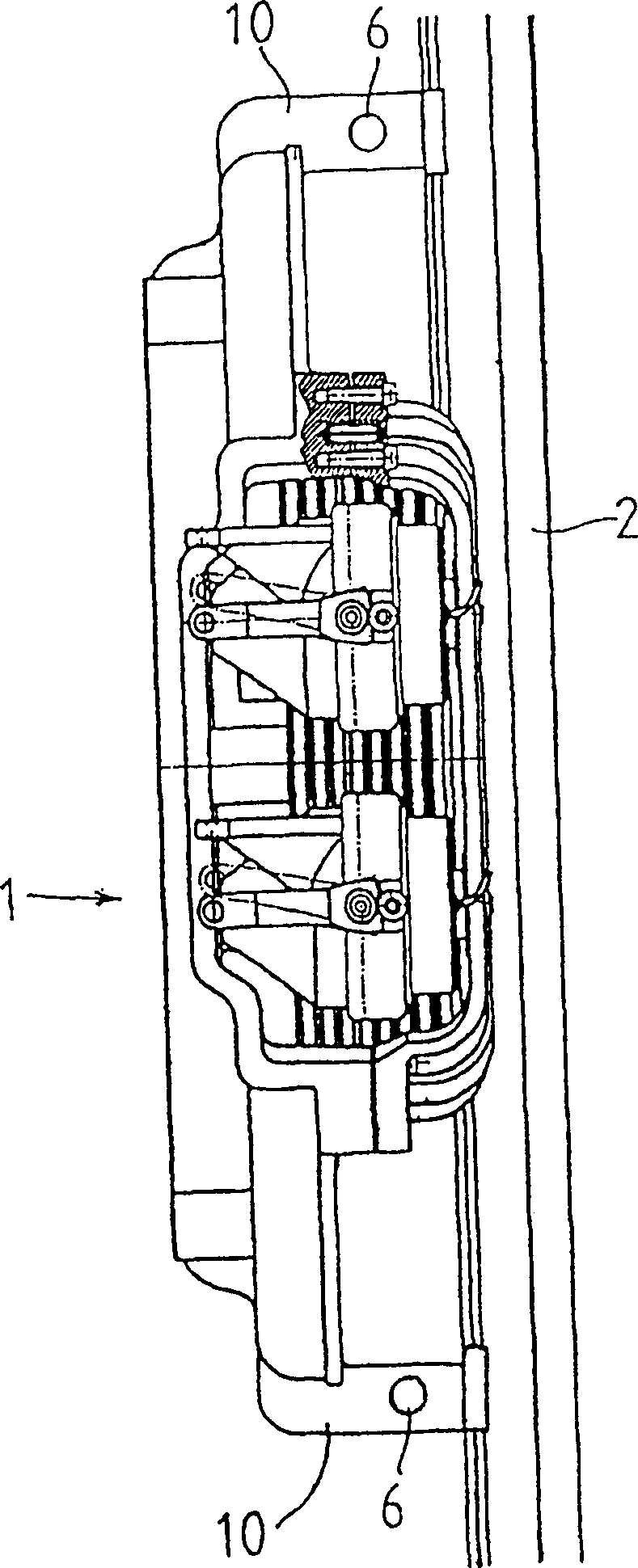

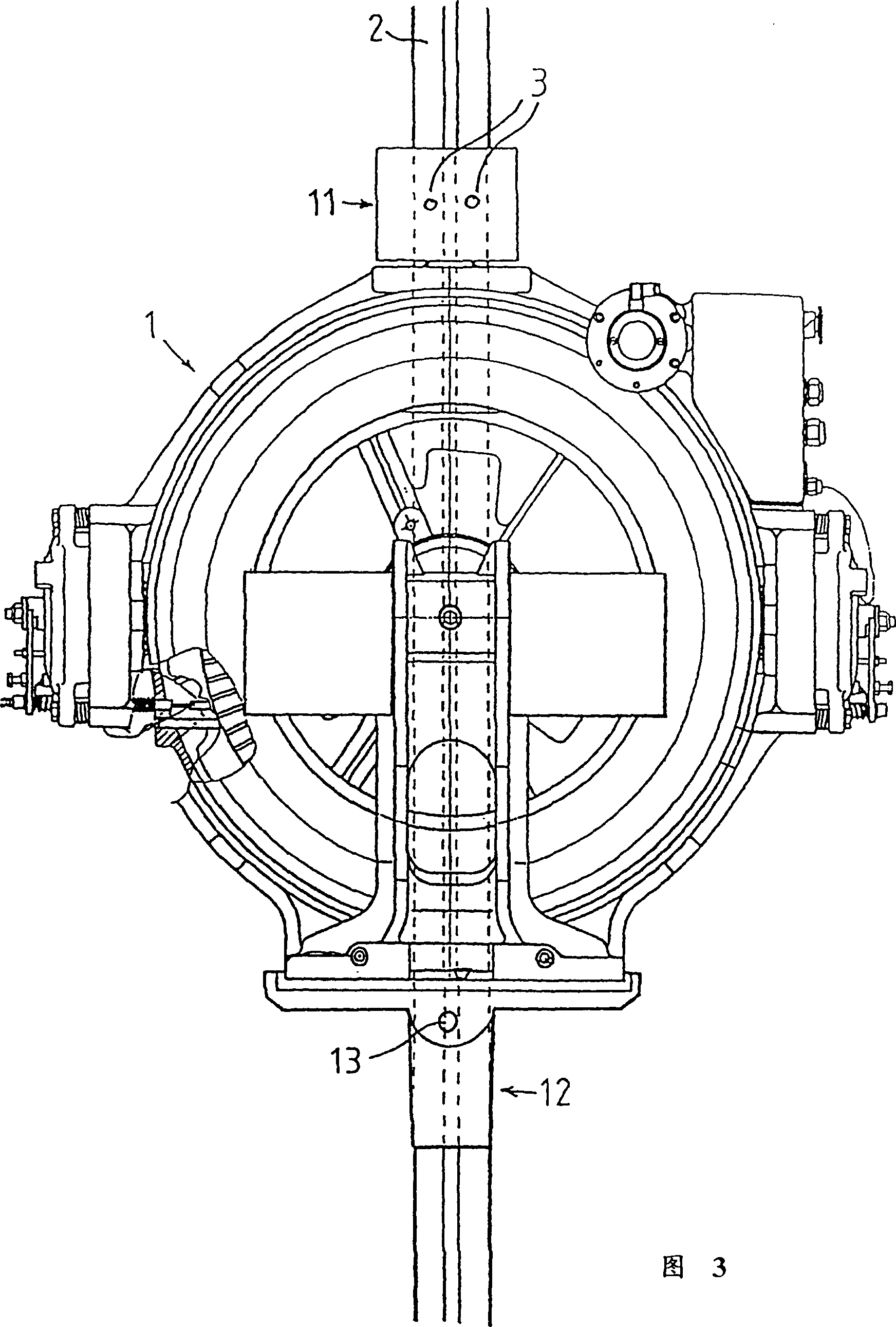

[0018] figure 2 A second embodiment of the invention is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com