Laminated composite water-proof structure with double side self adhesive water-proof coil as base layer and its construction method

A technology of self-adhesive waterproof membrane and waterproof structure, which is applied in the direction of building components, building insulation materials, etc., to achieve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

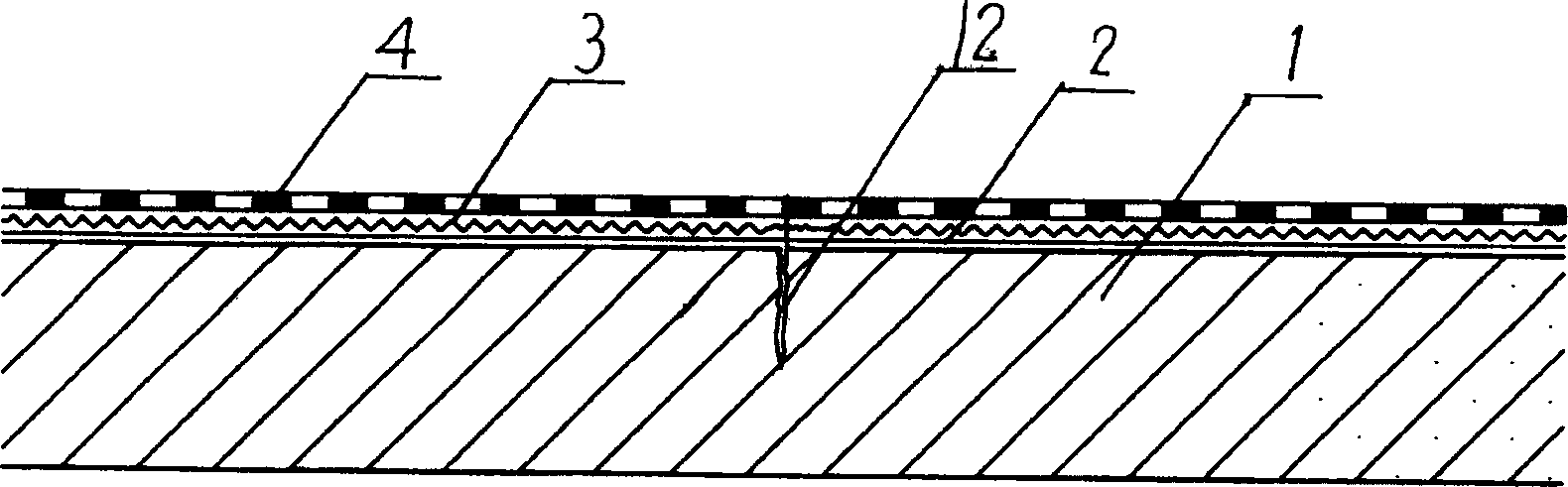

[0046] Example 1 as figure 1 Shown:

[0047] Base layer → base treatment agent → double-sided self-adhesive waterproof membrane layer → one layer of ordinary membrane waterproof layer 4;

Embodiment 2

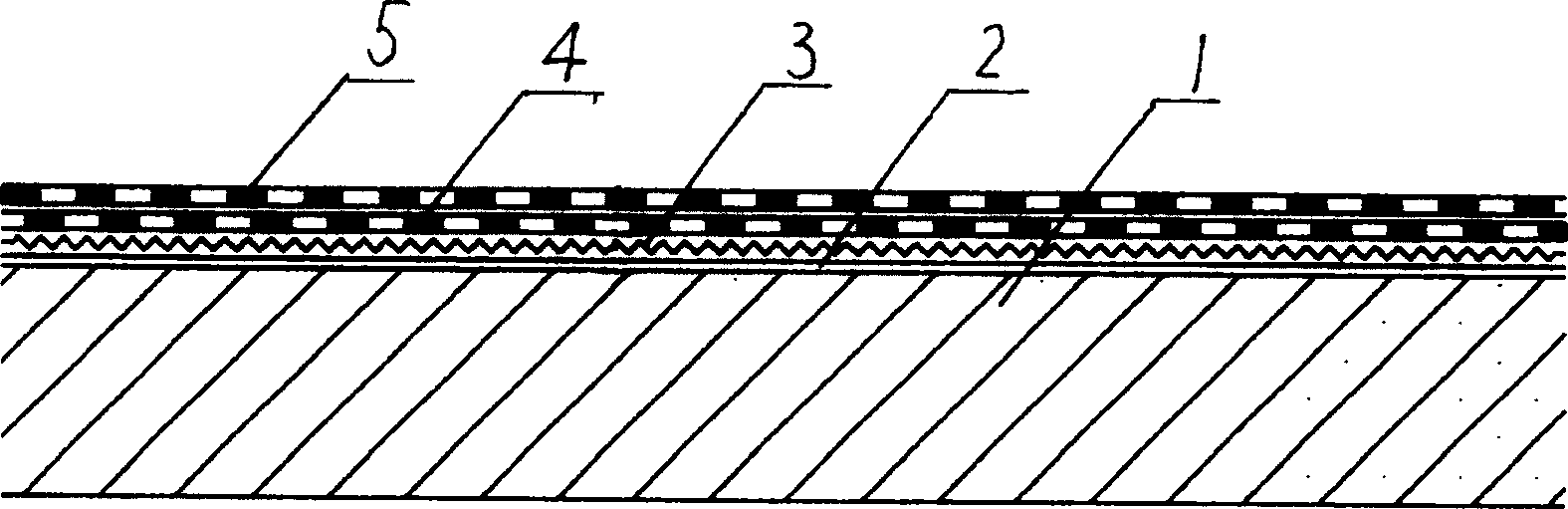

[0048] Example 2 as figure 2 Shown:

[0049] Base layer → base treatment agent → double-sided self-adhesive waterproof membrane layer → two layers of ordinary polymer waterproof membrane layer 4, 5;

[0050] Base layer → base treatment agent → self-adhesive waterproof membrane layer → polymer waterproof coating → polymer waterproof membrane layer;

[0051] Base layer → base treatment agent → double-sided self-adhesive waterproof membrane layer → metal waterproof membrane layer → polymer waterproof membrane layer;

[0052] Base layer → base treatment agent → double-sided self-adhesive waterproof membrane layer → polymer waterproof membrane layer → metal membrane layer;

[0053] Base→base treatment agent→double-sided self-adhesive waterproof membrane layer→polymer modified asphalt membrane waterproof layer→polymer modified asphalt layer

[0054] The above are a few examples of the double-layer waterproof layer, and the double-layer waterproof layer is a waterproof layer abov...

Embodiment 3

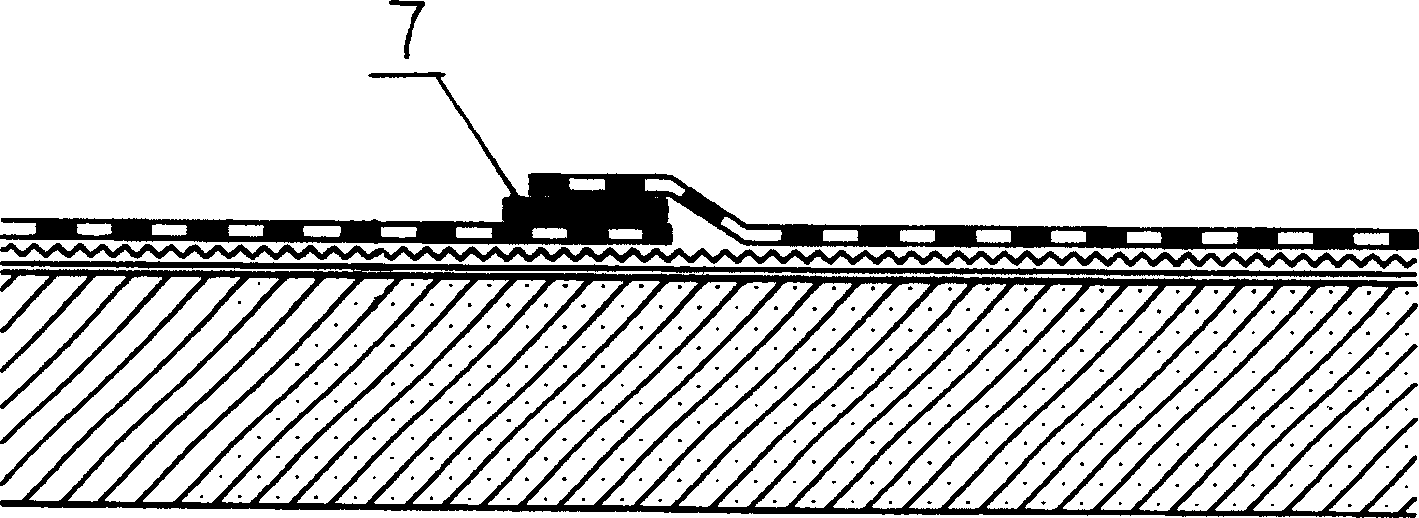

[0055] Example 3 as image 3 Shown: Adhesive sealing tape 7 between the lapped edges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com