Wafer atmospheric transport module having controlled mini-environment

A manufacturing method, atmospheric pressure technology, applied in the direction of conveyor objects, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as residue, mental confusion, and difficult cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

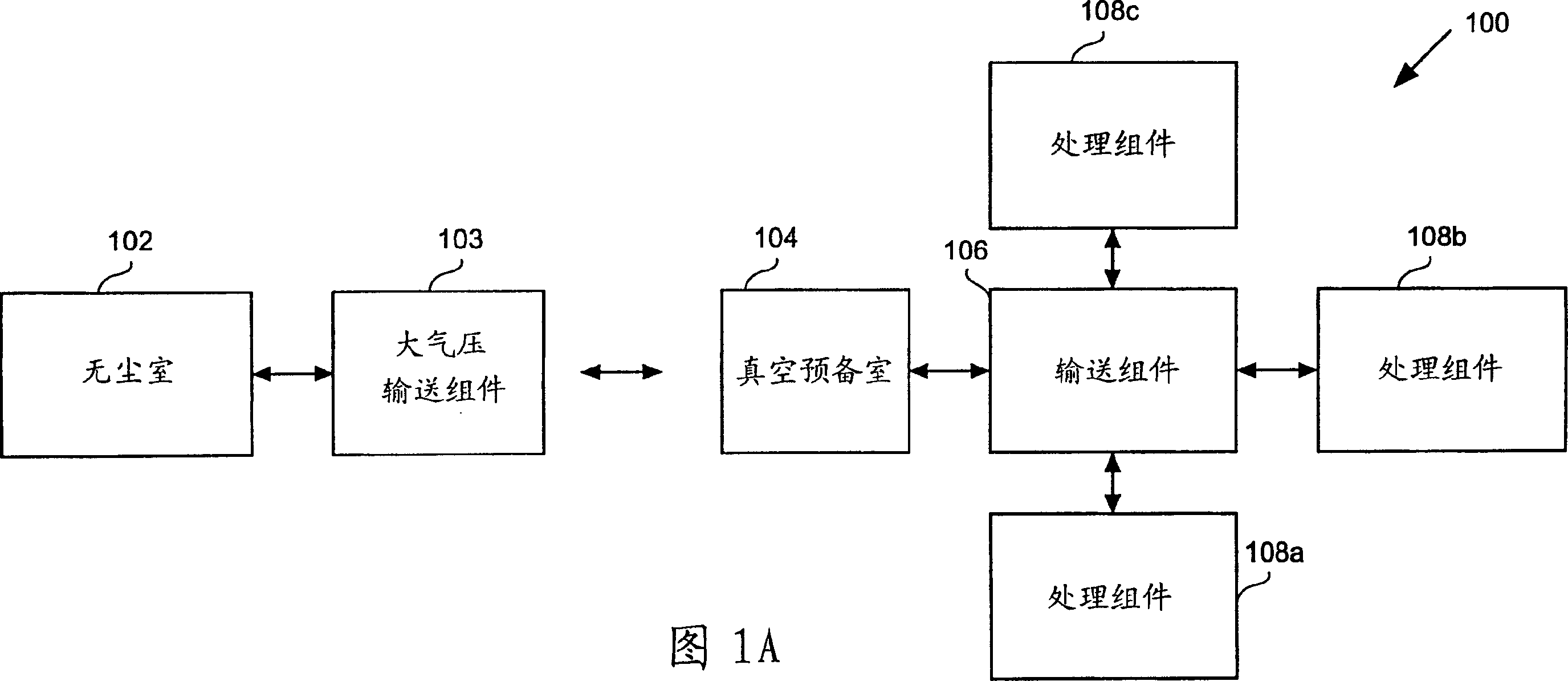

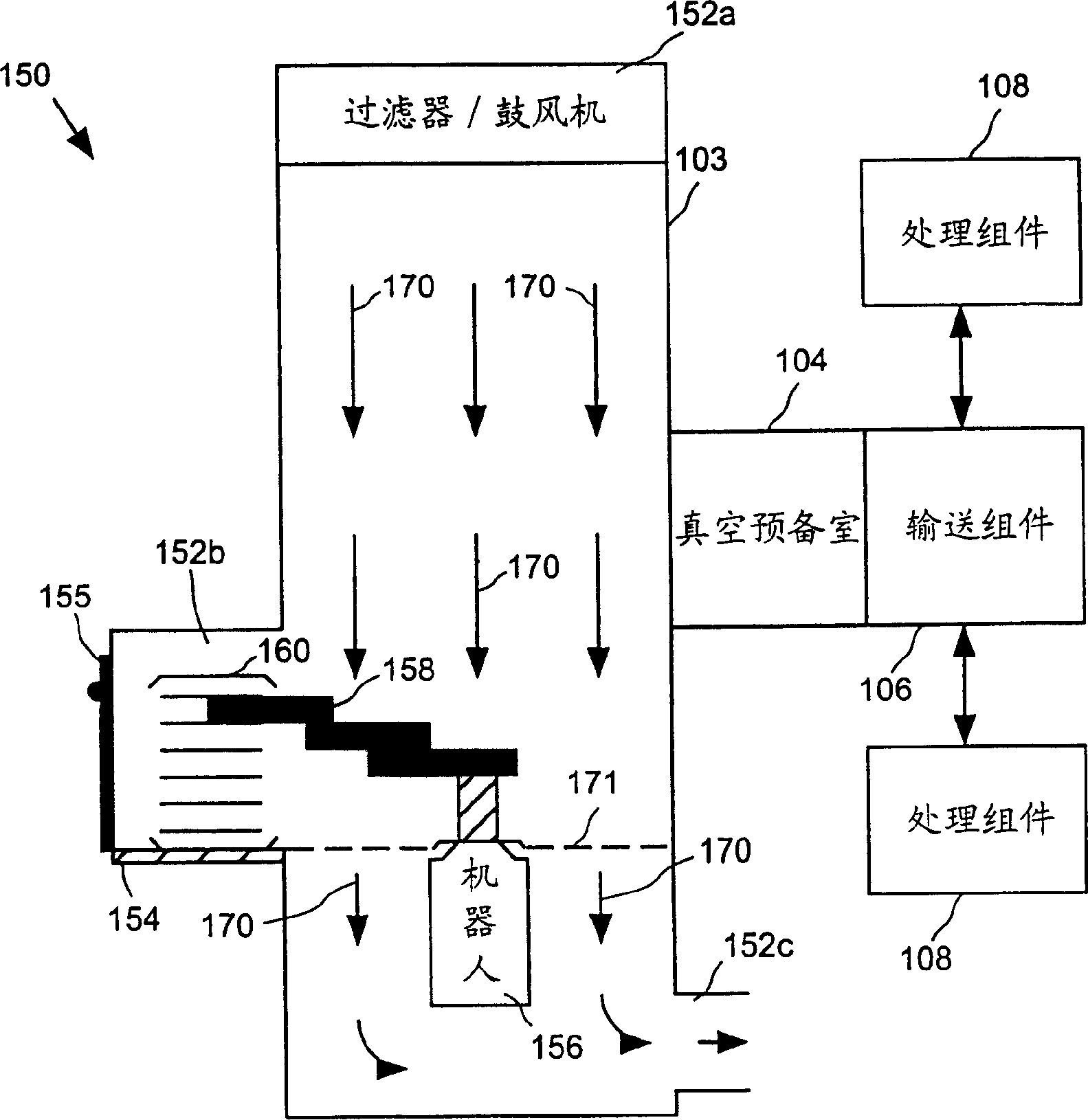

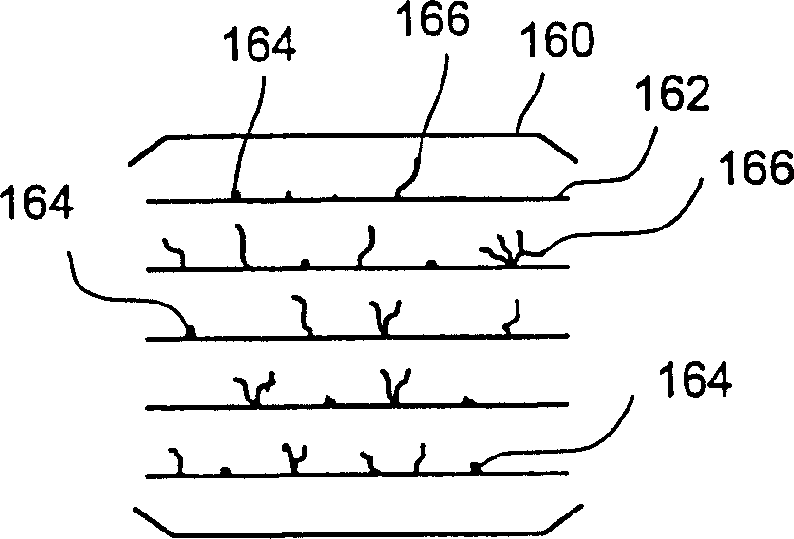

[0024] The present invention describes an atmospheric transport assembly that can create a miniaturized environment in the area where wafer cassettes are temporarily stored during processing. The compact environment preferably includes a gas flow through and substantially parallel to the wafers so that process gases and by-products can be substantially purged from between the wafers in the wafer basin. It will be apparent, however, to one skilled in the art that the present invention may be practiced without some or all of these specific details. In other words, well-known processing operations will not be described in detail here in order not to obscure the present invention.

[0025] According to an embodiment of the present invention, Figure 2A An atmospheric transfer module (ATM) 200 is shown resting on a clean room floor 201 . The ATM 200 includes a top 200a having a filter and a variable speed blower. Alternatively, the variable speed blower may be a fixed speed blowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com