Electric machine

A technology of electric machines and hubs, which is applied in the direction of synchronous generators, electrical components, electromechanical devices, etc., and can solve the problems that liquids and small particles cannot be sealed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

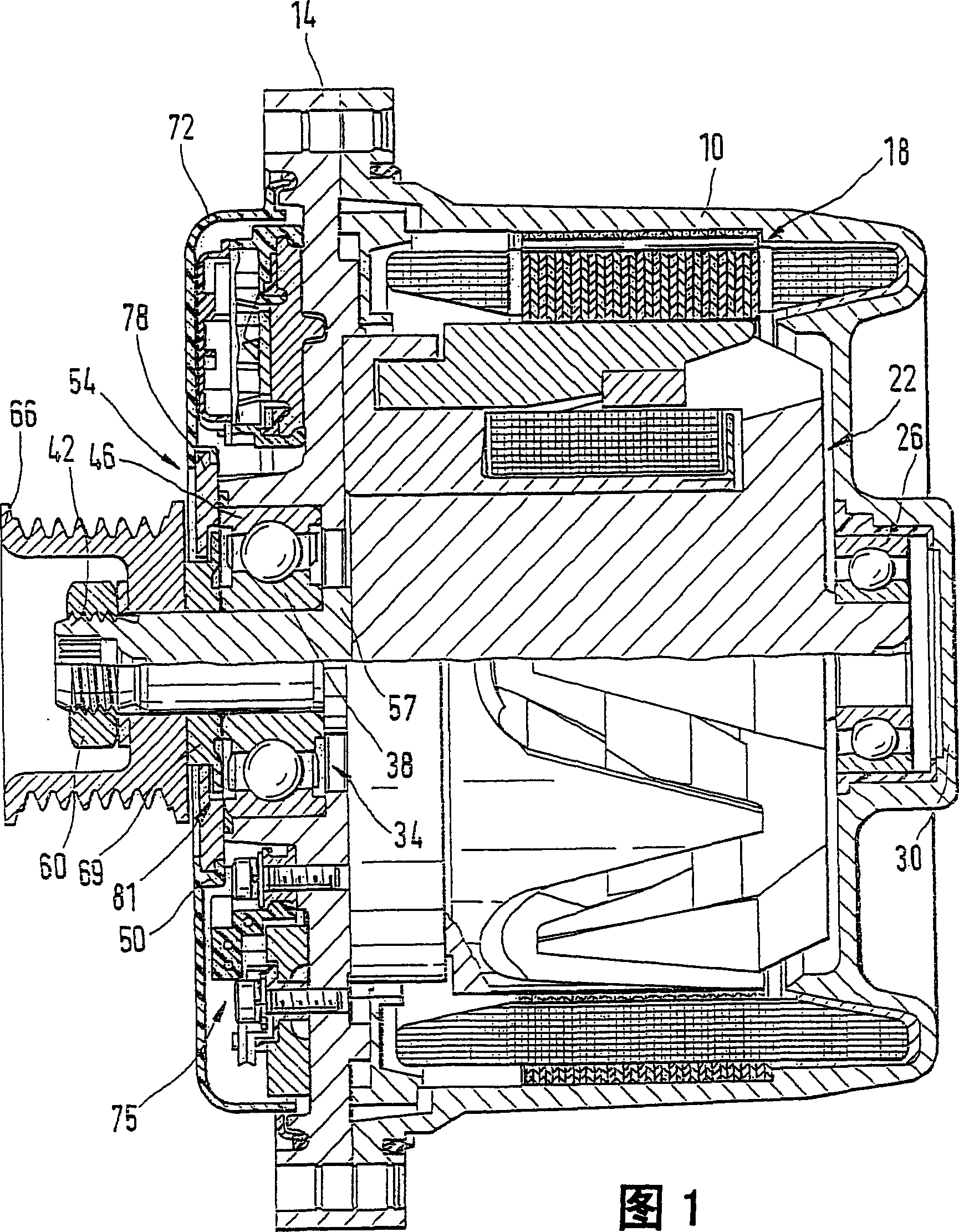

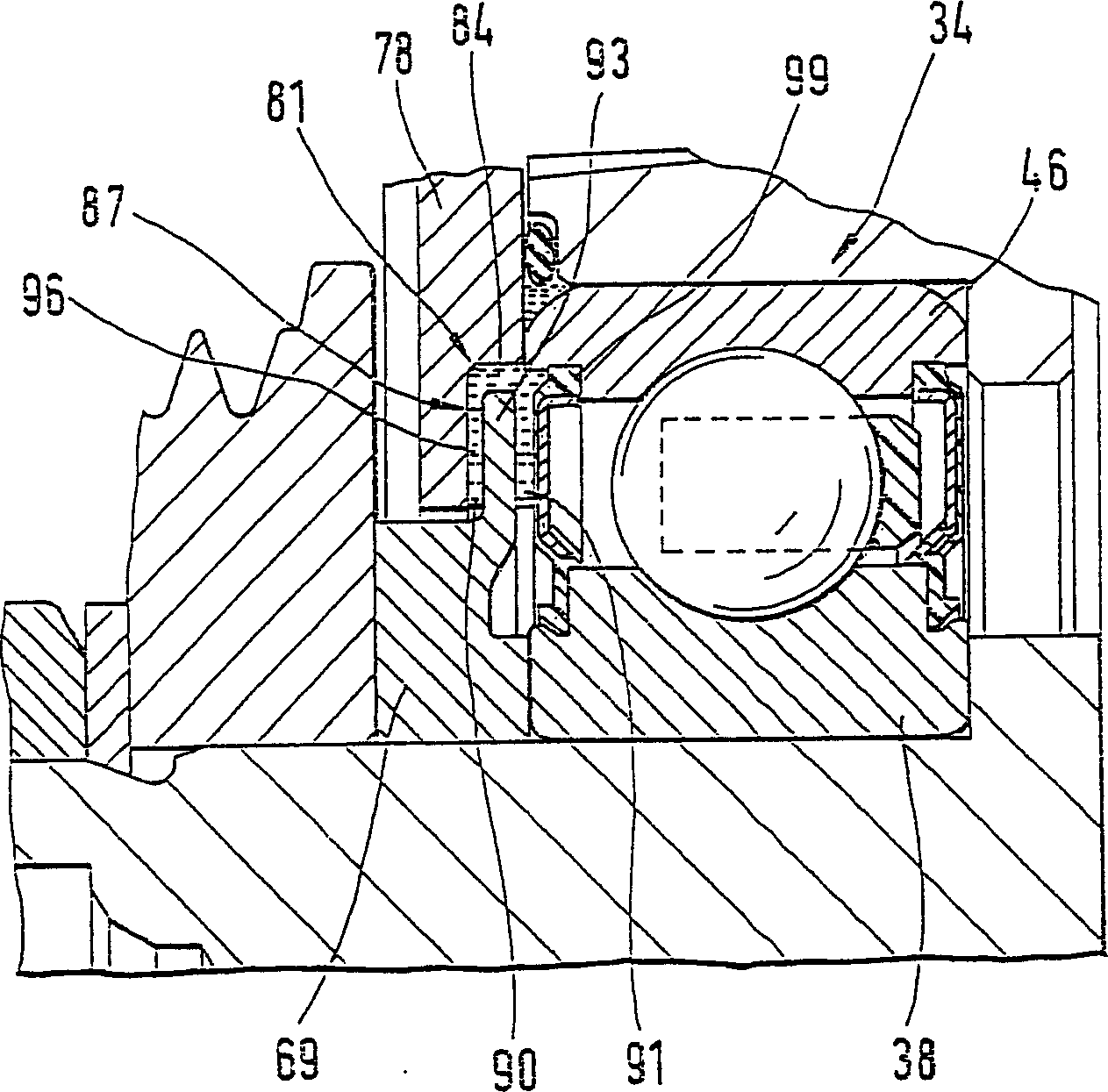

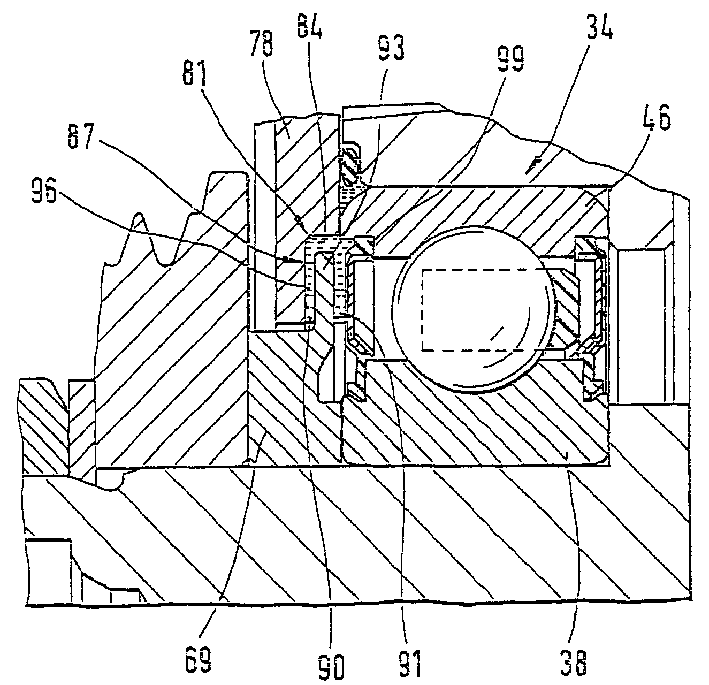

[0011] The upper half of FIG. 1 shows a longitudinal sectional view of the electrical machine according to the invention. The electrical machine, here in the form of a generator, has a pot-shaped housing 10, which is closed by a housing cover 14, in which a stator 18 is fastened, which surrounds the The shape surrounds a rotor 22. The rotor 22 is supported on one side via a bearing 26 on the housing base 30 and on the other side via a roller bearing 34 in the housing cover 14 . In this case, the rolling bearing 34 is supported on a rotor shaft 42 via a shaft-side bearing ring 38 . On the hub side, the roller bearing 34 is supported in the housing cover 14 via a hub-side bearing ring 46 . Here, the housing cover 14 forms a hub 54 with a shoulder 50 . The axial position of the shaft-side bearing ring 38 is limited by a shaft shoulder 57 , and the shaft-side bearing ring 38 passes through a shoulder 63 of a pulley 66 by means of a nut 60 and a second shaft arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com