Artificial distiller's yeast culturing process

A cultivation method and pit mud technology are applied in the preparation of alcoholic beverages, which can solve the problems of insufficient nutrition, deduction of points, and inadequate cultivation.

Inactive Publication Date: 2005-03-16

SICHUAN TUOPAI SHEDE WINE

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

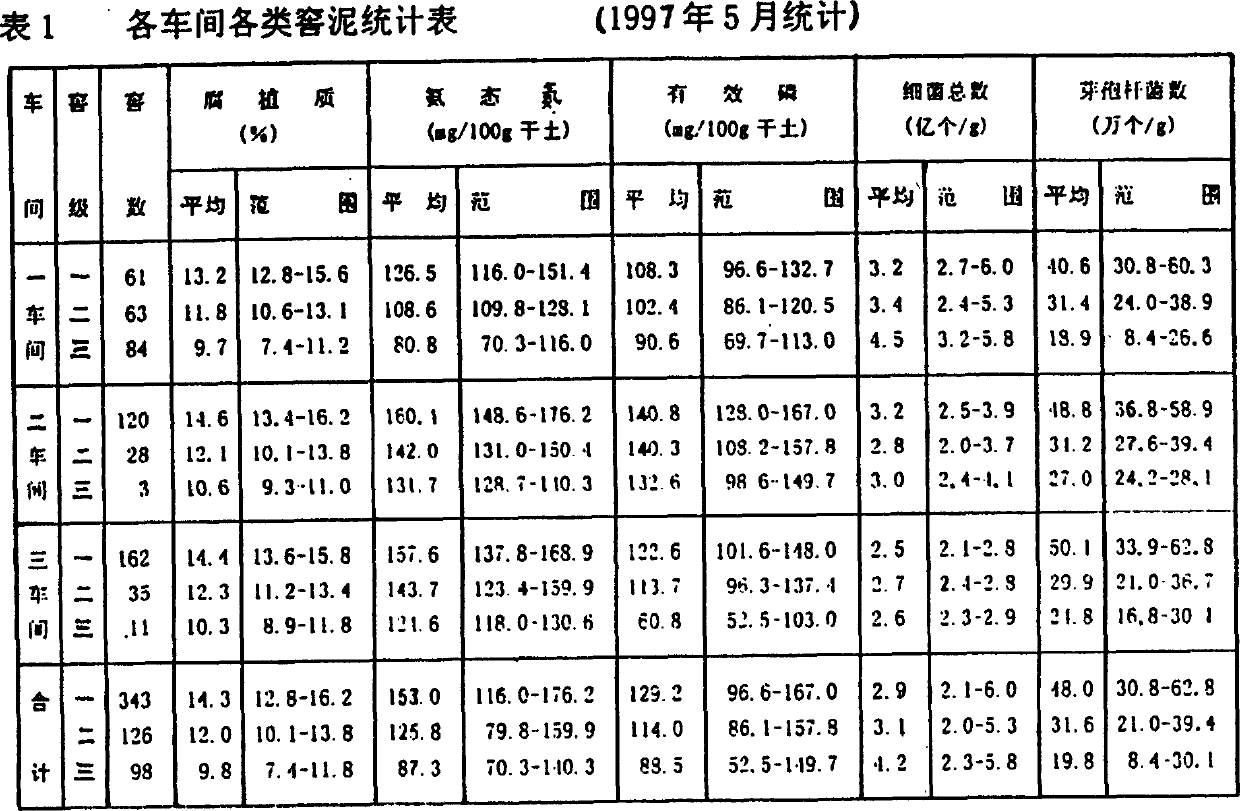

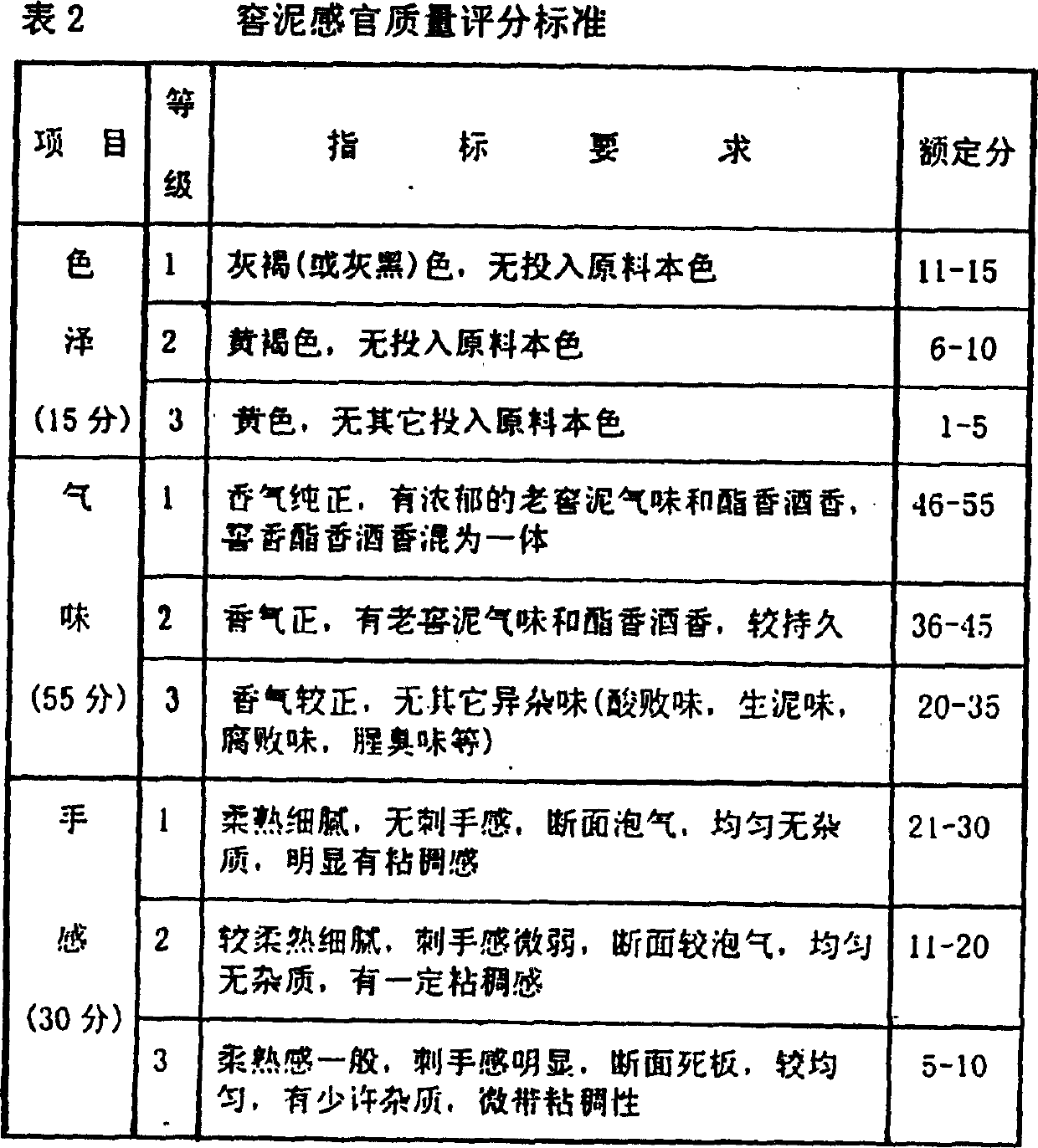

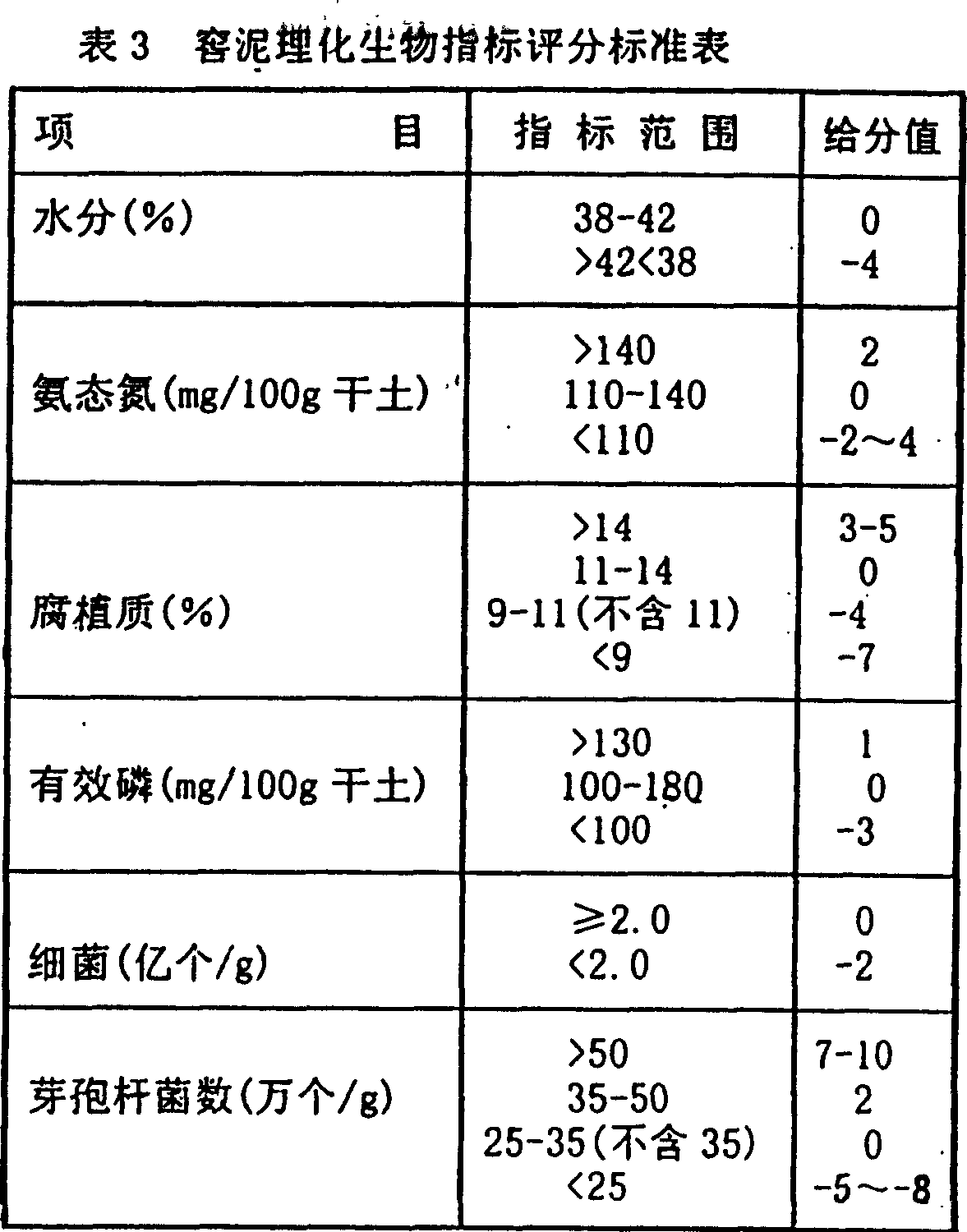

But a certain amount of bacteria also reflects the nutritional status of pit mud, so a basic requirement is given when scoring. If the basic requirement is not met, it is mostly due to insufficient nutrition or improper cultivation, and points will be deducted

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0084] Tuopai Qu Distillery has been cultivating pit mud for several years, combined with raw material resources of the factory, a large number of laboratory data and the laws of microbial growth and metabolism, selected such as bacterial fermentation liquid, gastric tumor microbial fermentation liquid and high-quality pit mud preparation The formula and cultivation method (same as before, omitted).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The present technological process is characterized by that the preparation of cellar mud is implemented by continuously making primary culture, second culture and third culture. For primary culture using cellar skin mud, koji powder (its dose is 1-2% of cellar skin mud), spent grains powder (its dose is 10-15% of cellar skin mud) and rumen microbiological fermenting liquor (its dose is 40-46% of the above-mentioned mixed material), uniformly mixing the above-mentioned materials, piling forming and sealing for 35 days, controlling temp. at 34-45 deg.C; for second culture, detecting product after primary culture, if it meets standard, further adding koji powder 3%, spent grains powder 1-2%, piling, forming, sealing and fermenting for 35 days, controlling temp. at 35-45 deg.C; and for third culture, sampling from the product after second culture, if it meets standard, adding 2% koji powder, 3-5% inoculum fermenting liquor, continuous fermenting in cellar for 35 days, sampling, judging, if it completely meets standard of quality, curing for 2 months, so that it can be used.

Description

technical field [0001] The invention relates to a process for aging with artificial pit mud, in particular to a process for brewing Daqu wine and cultivating high-quality artificial pit mud for aging in a short period of time. Background technique [0002] An important feature of the production of Luzhou-flavor Daqu liquor is mud cellar fermentation. Pit mud is the carrier and nutrient bank for microorganisms such as ester-producing aroma, acid-producing and flavor-producing microorganisms. The quality of pit mud is closely related to the quality and body style of koji liquor, so the quality of pit mud is the key to the production of Luzhou-flavor koji liquor, and all manufacturers attach great importance to it. [0003] New cellars are put into production and rectification of aging cellars requires new cellar mud. Especially for a national famous winery like Tuopai, which is expanding and growing, the demand for new pit mud and the quality of pit mud are very high. The t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C12G3/00C12G3/02C12H1/00

Inventor 李家明

Owner SICHUAN TUOPAI SHEDE WINE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap