Small electric motor

A kind of electric motor and small technology, which is applied in the direction of manufacturing motor generators, electric components, electrical components, etc., and can solve the problems of narrow space, restrictions, and large radial direction for disposing the gear train part 215

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

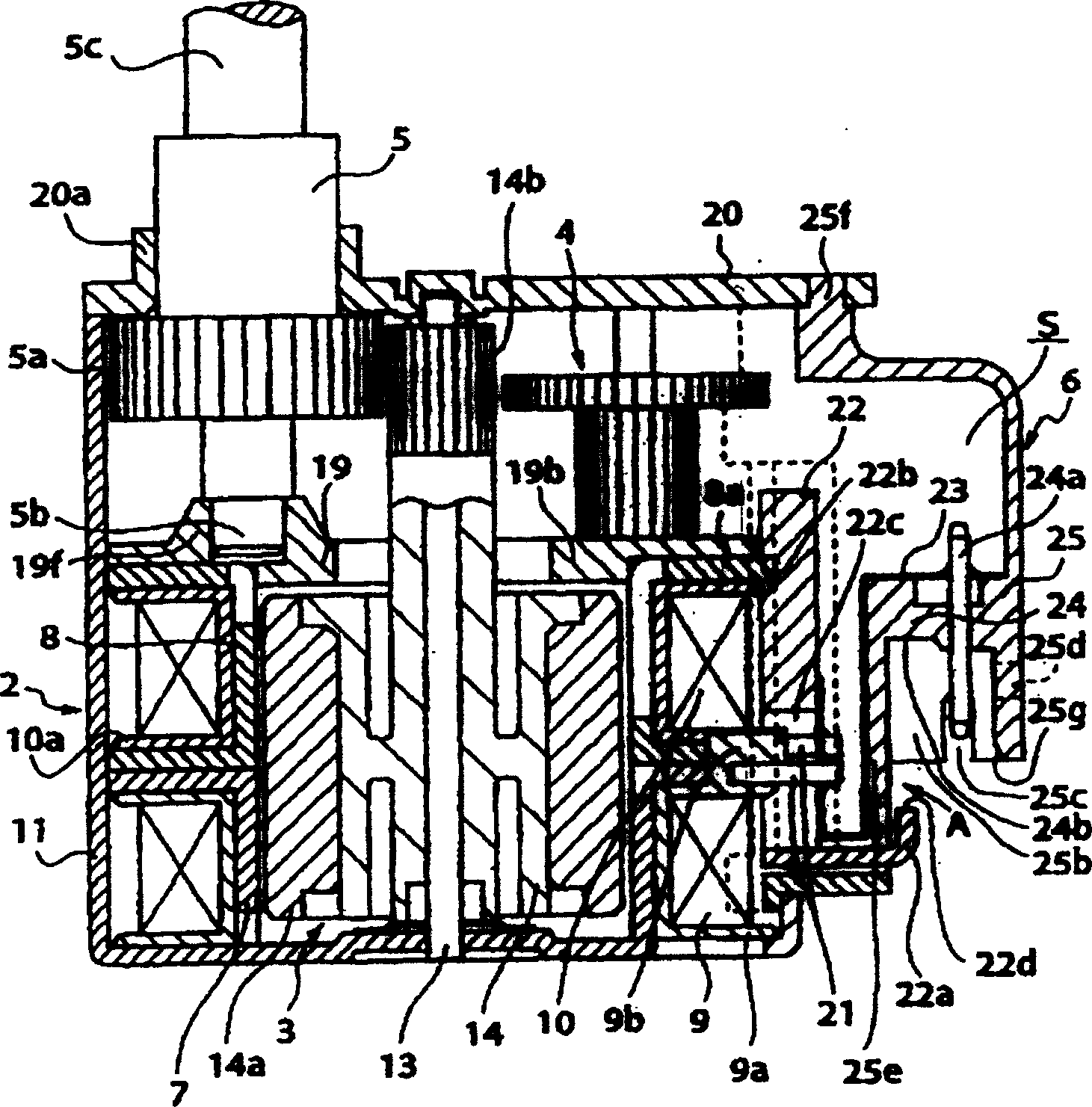

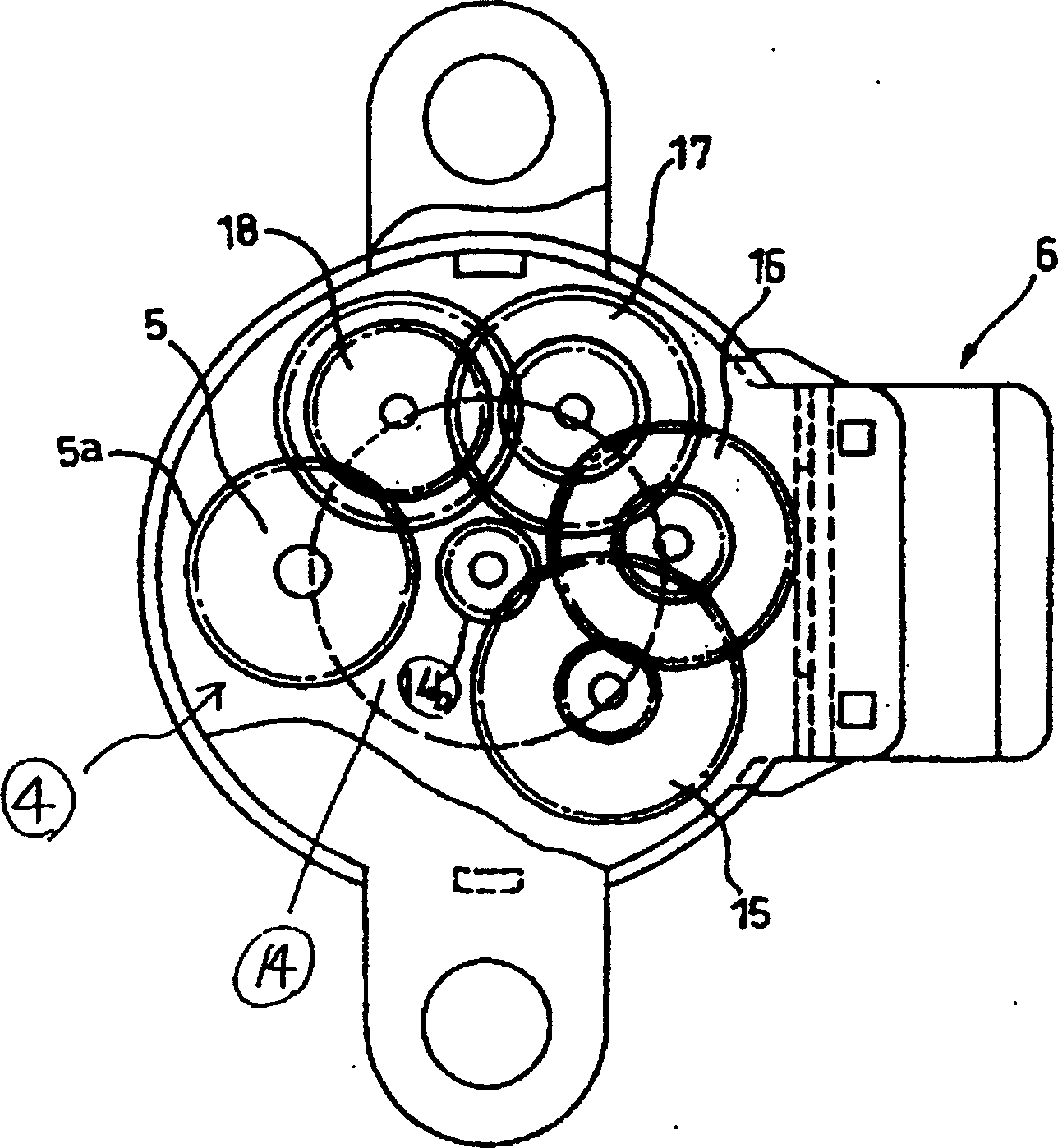

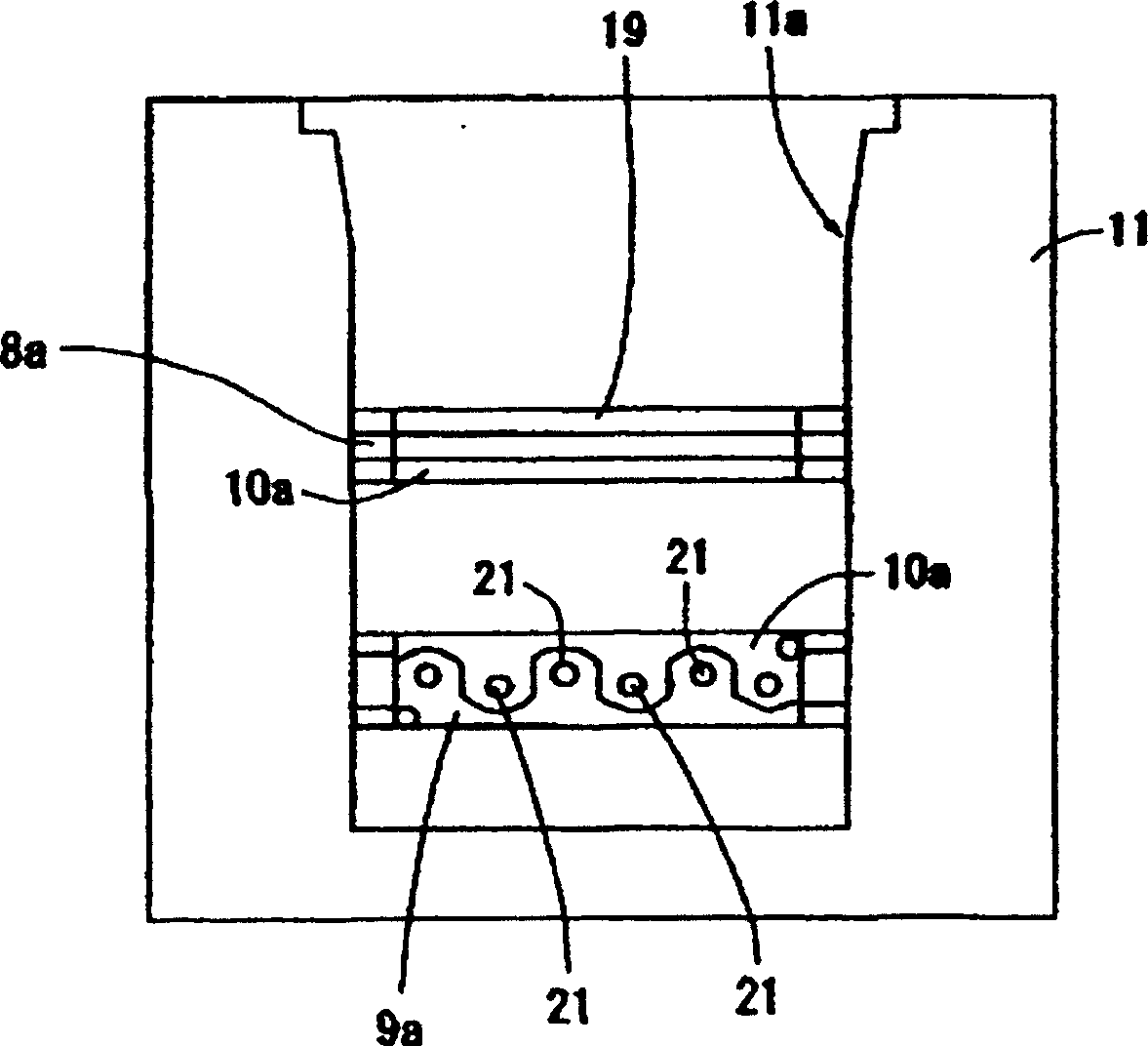

[0031] Combine now Figure 1 to Figure 10 Embodiments of the present invention will be described. combine first Figure 1 to Figure 8 The small motor of the first embodiment will be described.

[0032] First, use figure 1 and Figure 4 to Figure 7 The structure of the terminal part and the support base which are the key points of the present invention will be described. The connecting member 6 of the terminal portion is a connecting portion 24 to be connected to a connector inserted from the outside, and a cover portion 25 having an opening 25b that serves as an accommodating space for the connector inserted from the outside, and is integrated by fixing or synthetic resin. Formed into a structure that integrates the two.

[0033] The connecting portion 24 is provided integrally with the cover portion 25 at the center of the cover portion 25 described later, and holds the connector pins 24a and the flexible substrate 23 constituting the conduction path.

[0034] cover pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com