Phosphatide swelled feed for cow and preparation method thereof

A technology of extruded feed and phospholipids, which is applied in animal feed, animal feed, additional food elements, etc., can solve the problems of dairy cows’ reproductive growth and milk production negative impact, unfavorable digestion and absorption of dairy cows, and containing harmful microorganisms, so as to promote absorption and utilization , improve taste and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

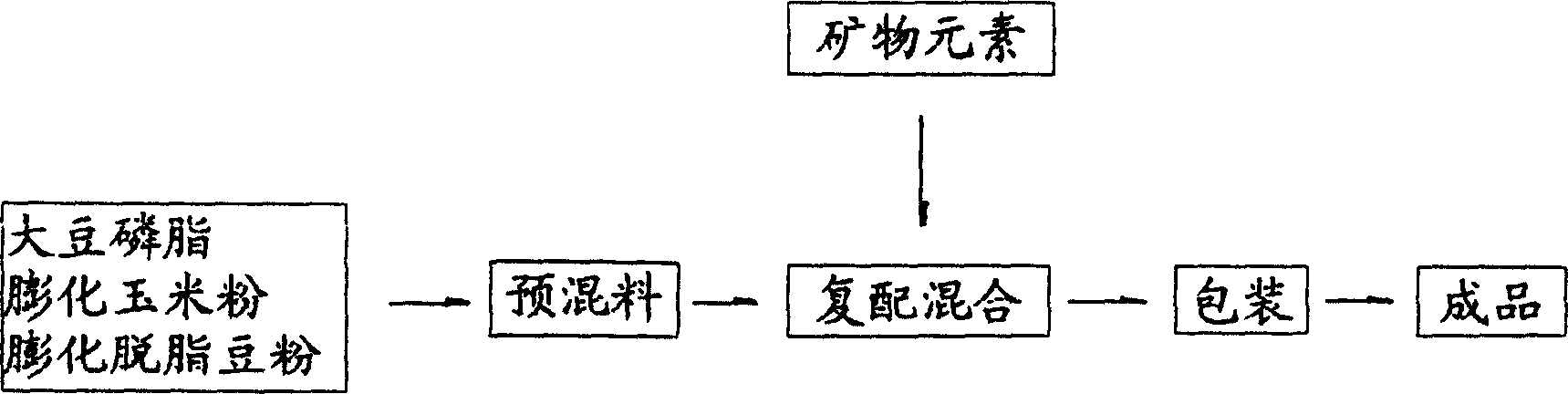

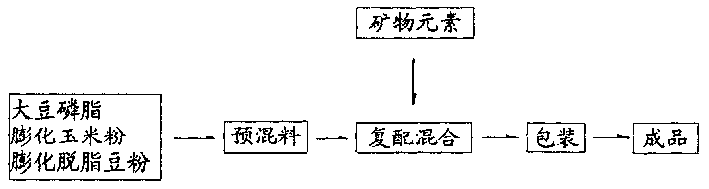

Method used

Image

Examples

Embodiment Construction

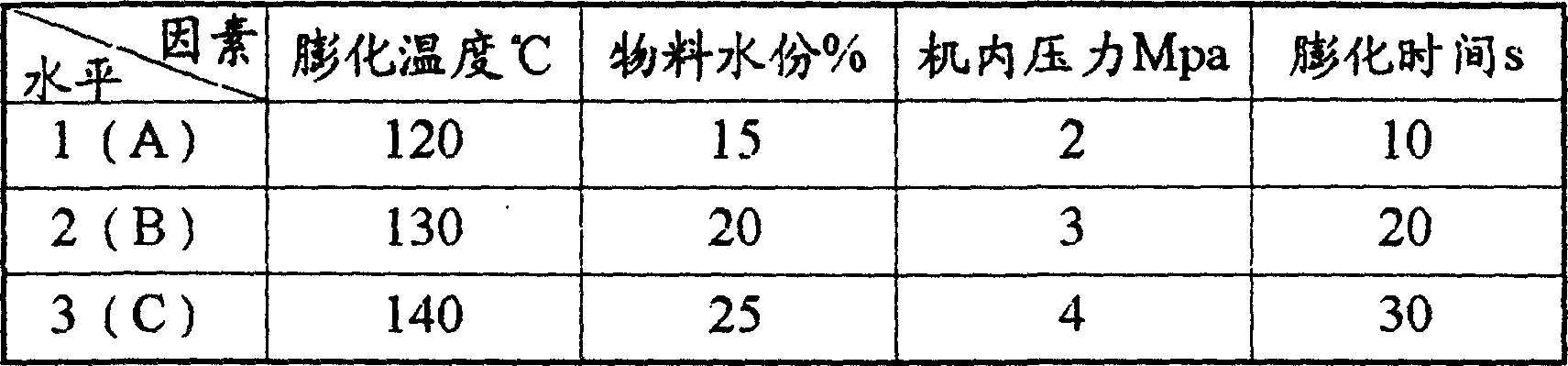

[0020] Optimizing and determining the four optimum parameters of the extruding process of temperature, pressure, time and material water content to achieve the purpose of improving digestibility and animal production performance. The experimental design and results are as follows:

[0021] Table 1 Selection of factors and levels of orthogonal experiment

[0022]

[0023] Table 2 Test arrangement and test results

[0024]

[0025] From the experimental results in Table 2, it can be seen that among the four factors that have the greatest impact on each index is the puffing temperature, followed by the moisture content of the material, followed by the internal pressure and puffing time factors. The best combination of all factors is Experiment No. 5. That is, the puffing temperature is 130°C, the moisture content of the material is 20%, the internal pressure is 3Mpa, and the puffing time is 20s, which are the optimum conditions for the optimized and definite puffing process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com