Non-aqueous electrolyte and non-aqueous electrolyte secondary cell

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, non-aqueous electrolyte, secondary batteries, etc., can solve the problems that secondary batteries cannot be obtained, long charge and discharge cycle life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0201] (production of positive electrode)

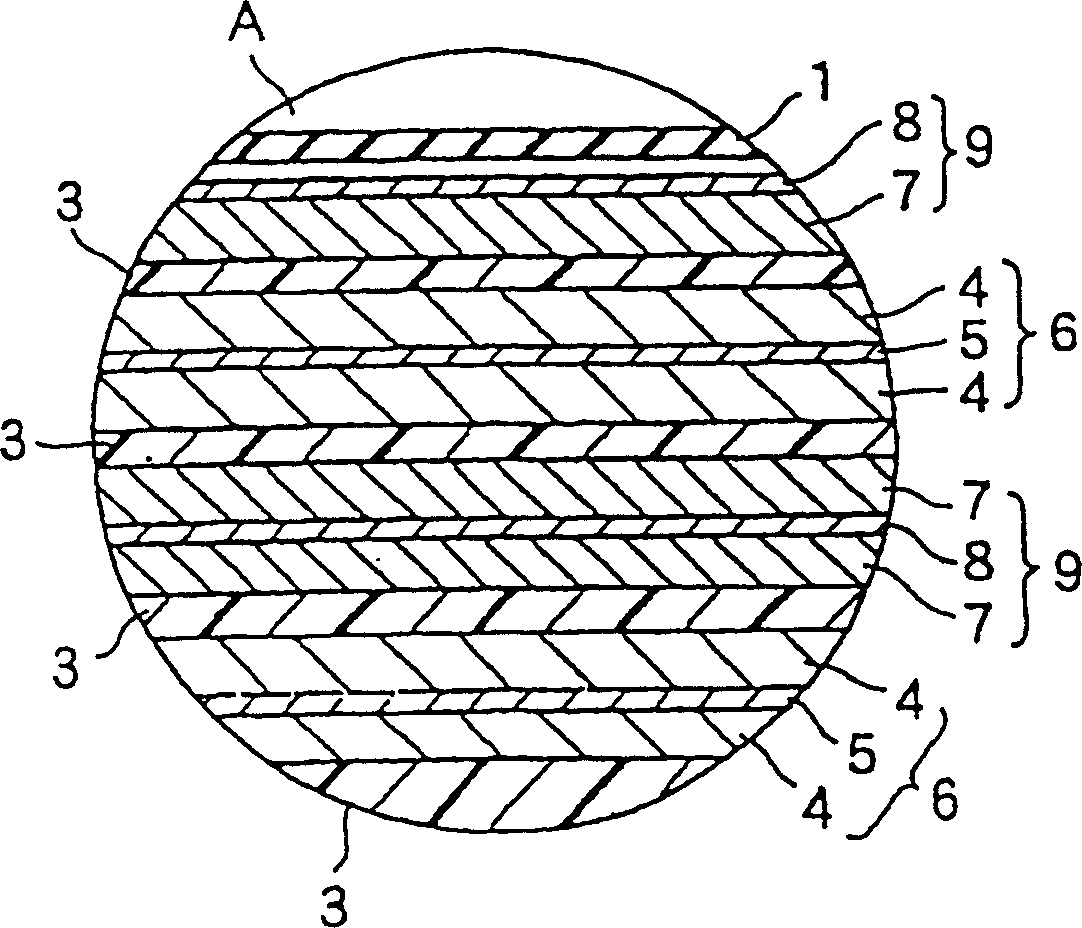

[0202] First, mix 91% by weight lithium cobalt oxide (Li x CoO 2 , x satisfies 03 Both sides of the current collector carry the positive electrode of the positive electrode layer.

[0203] (production of negative electrode)

[0204] Mix 93% by weight of mesophase pitch-based carbon fiber powder (fiber diameter is 8 μm, average fiber length is 20 μm, average interplanar spacing (d 002 ) is 0.3360nm) and 7% by weight of polyvinylidene fluoride (PVdF) as a binder, prepared into a slurry. The aforementioned slurry was coated on both sides of a current collector made of copper foil with a thickness of 12 μm, dried and pressed to obtain an electrode with a density of 1.4 g / cm 3 The current collector is loaded with negative electrode layers on both sides.

[0205] (compartment)

[0206] The separator was made of a polyethylene porous film having a thickness of 25 μm, a thermal shrinkage of 20% at 120° C. for 1 hour, and a porosity of ...

Embodiment 2~22

[0217] Except that the composition of the non-aqueous solvent was changed as shown in the following Table 1, other things were the same as in the foregoing Example 1, and a thin non-aqueous electrolyte secondary battery was produced.

Embodiment 23

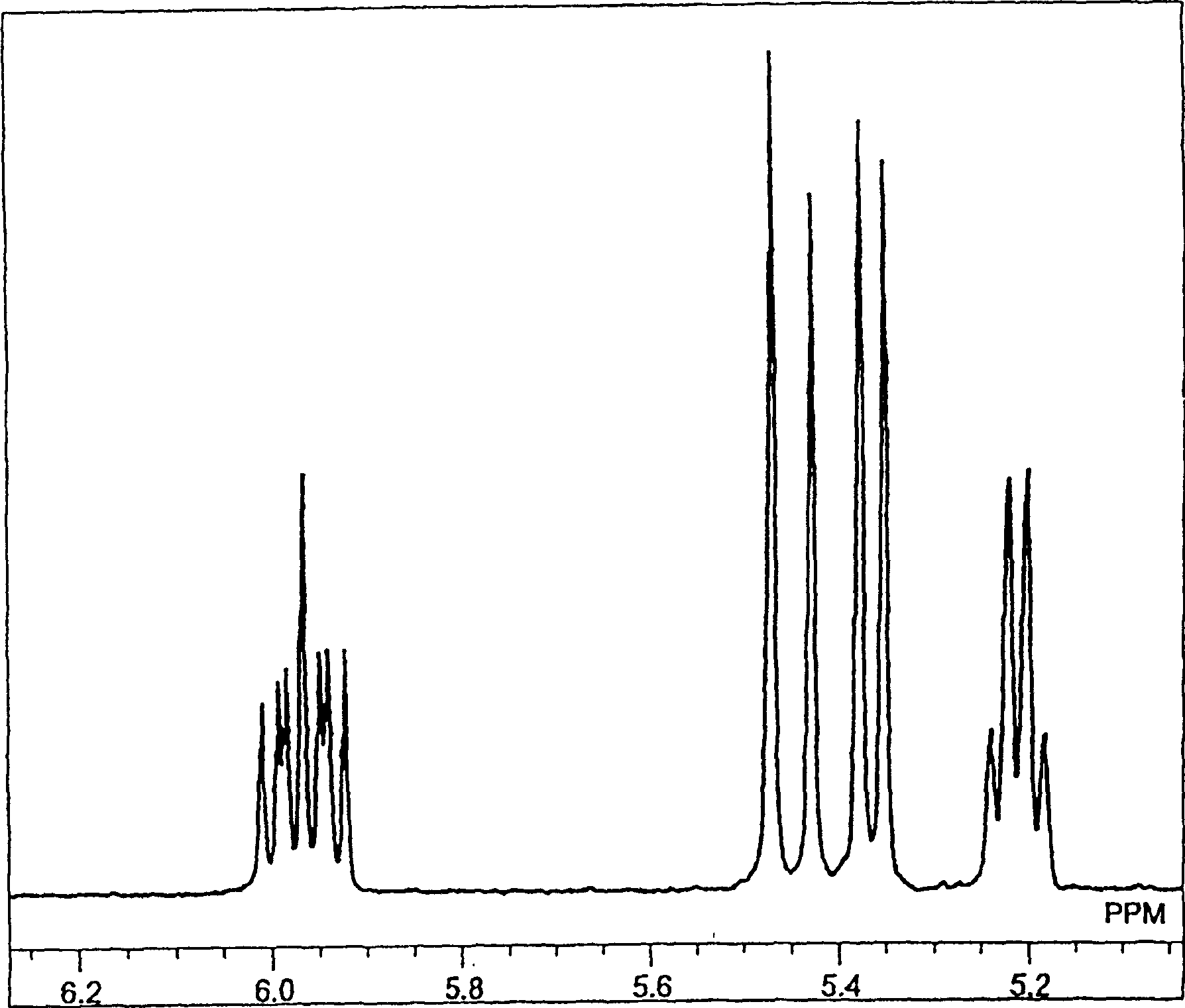

[0235] (Preparation of non-aqueous electrolyte solution)

[0236] Mix ethylene carbonate (EC), propylene carbonate (PC), γ-butyrolactone (BL) and vinylene carbonate at a volume ratio of 25:9:65:1 (EC:PC:BL:VC) (VC), prepared a non-aqueous solvent. Lithium tetrafluoroborate (LiBF 4 ) is dissolved in the obtained non-aqueous solvent, so that its concentration is 1.5 mol / liter, to obtain a non-aqueous electrolyte.

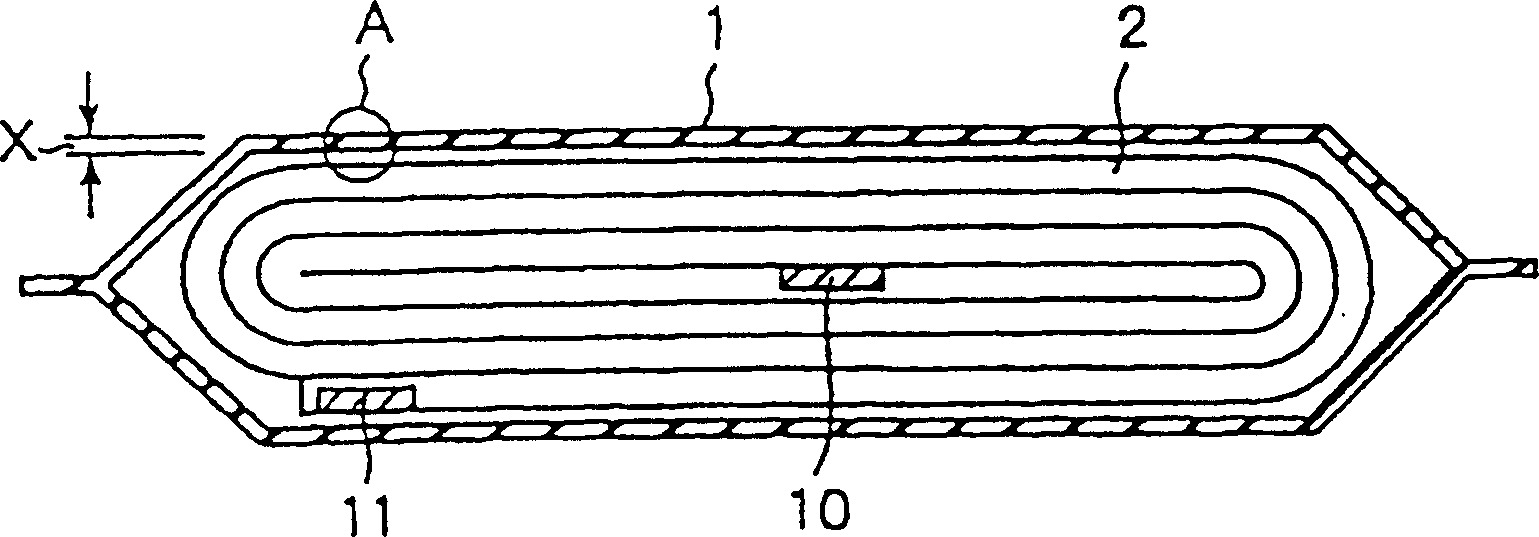

[0237] (Production of Electrode Group)

[0238] In the same manner as described in Example 1 above, a flat electrode group was produced. The electrode group was heated and extruded under the same conditions as in Example 1 to integrate the positive electrode, the negative electrode, and the separator.

[0239] An aluminum sheet with a thickness of 300 μm was formed into a rectangular parallelepiped aluminum case with a thickness of 4 mm, a width of 34 mm, and a height of 58 mm, and the aforementioned electrode group was incorporated therein.

[0240] Then, under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com