Oscillating motor and motor control equipment and method

一种振动电动机、电动机的技术,应用在交流电动机控制、用于单相电流的同步电动机、电动组件等方向,能够解决费用增加、不能做高速往复旋转运动、不能被应用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Reference will now be made to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

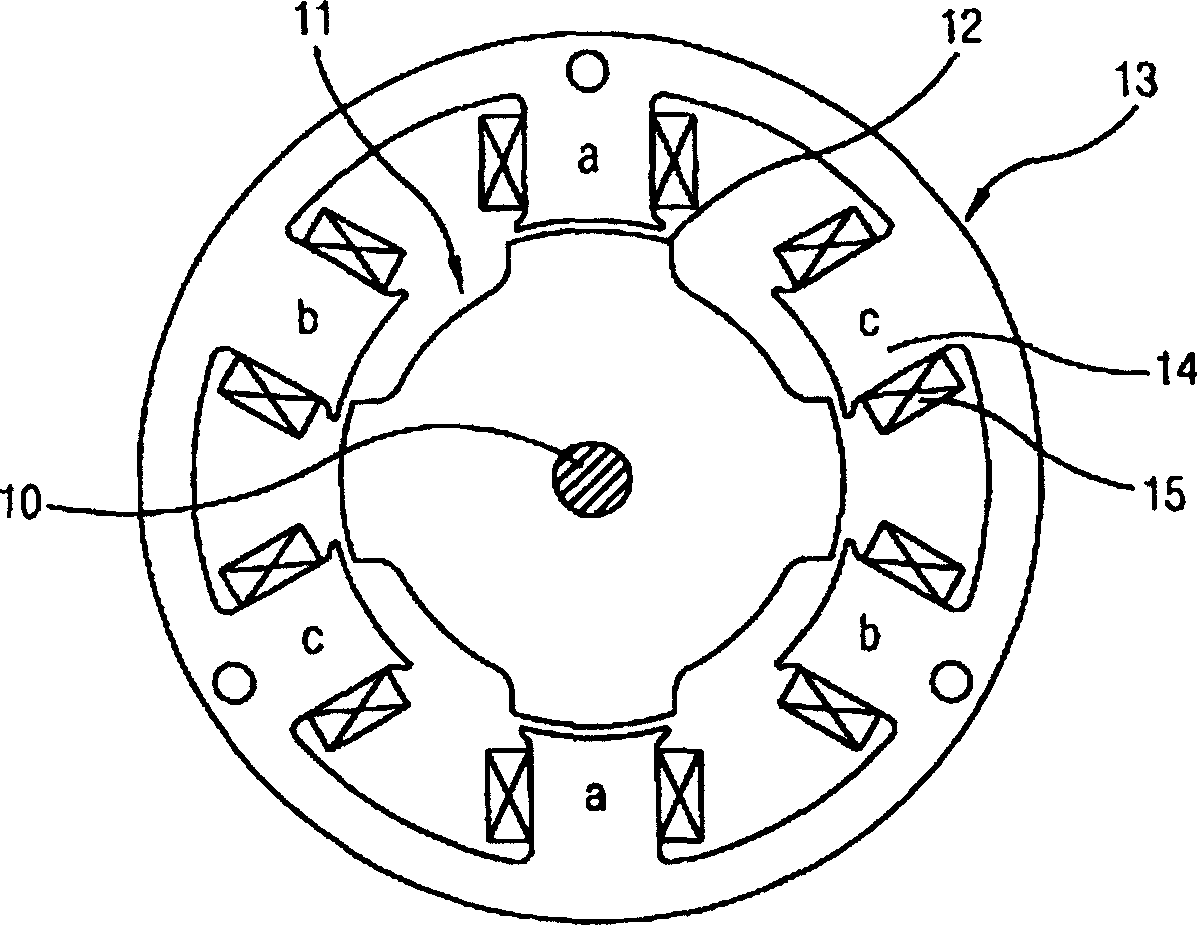

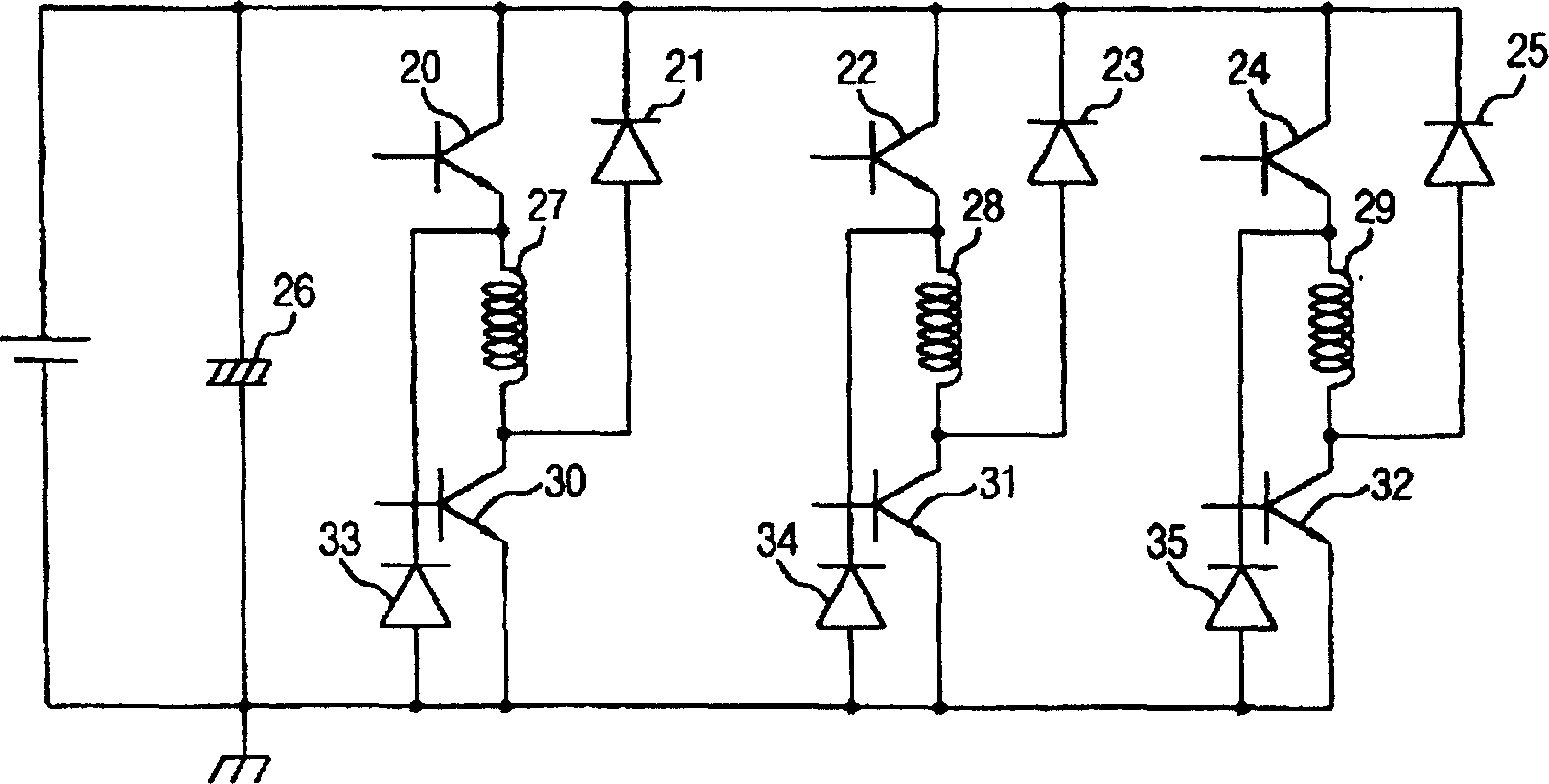

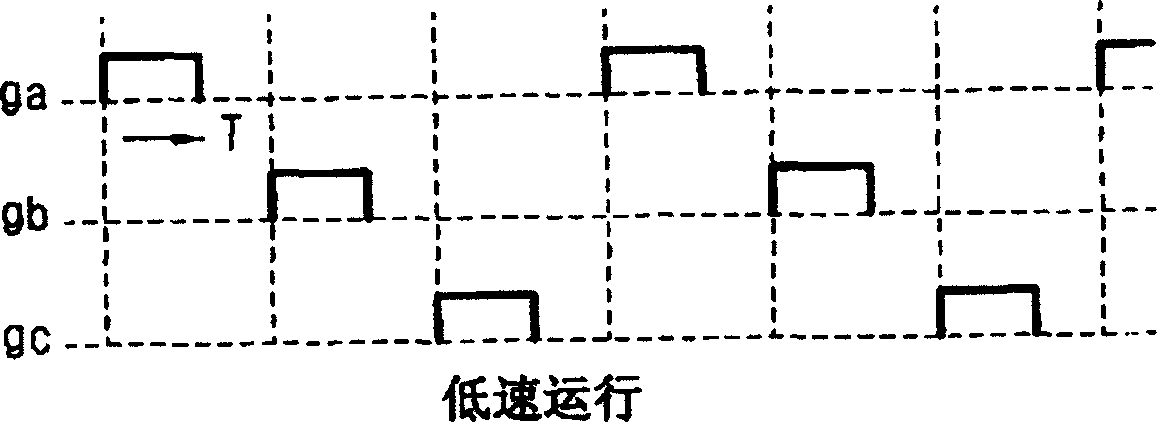

[0052] Figure 4 is a perspective view showing a vibration motor according to a preferred embodiment of the present invention, Figure 5 is a vertical sectional view of a vibration motor according to a preferred embodiment of the present invention, Image 6 is according to a preferred embodiment of the present invention along Figure 5 Sectional view taken along line 'f-f' of

[0053] As shown in the drawing, a stator 410 is provided, a rotor 440 is rotatable inside the stator 410, and a rotation shaft 470 is at the center of the rotor as an extraction shaft.

[0054] The stator 410 is provided with a stator core 420 stacked by laminations. A pair of stator teeth on which a coil is wound is formed in the reciprocating rotation areas 400 and 400 - 1 in front and rear of the inner circumferential surface of the stator core 420 exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com