Plane switch mode active matrix liquid crystal display device and mfg. method thereof

An active matrix, planar switch technology, used in static indicators, instruments, transistors, etc., can solve problems such as not being able to completely shield and reduce the impact of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

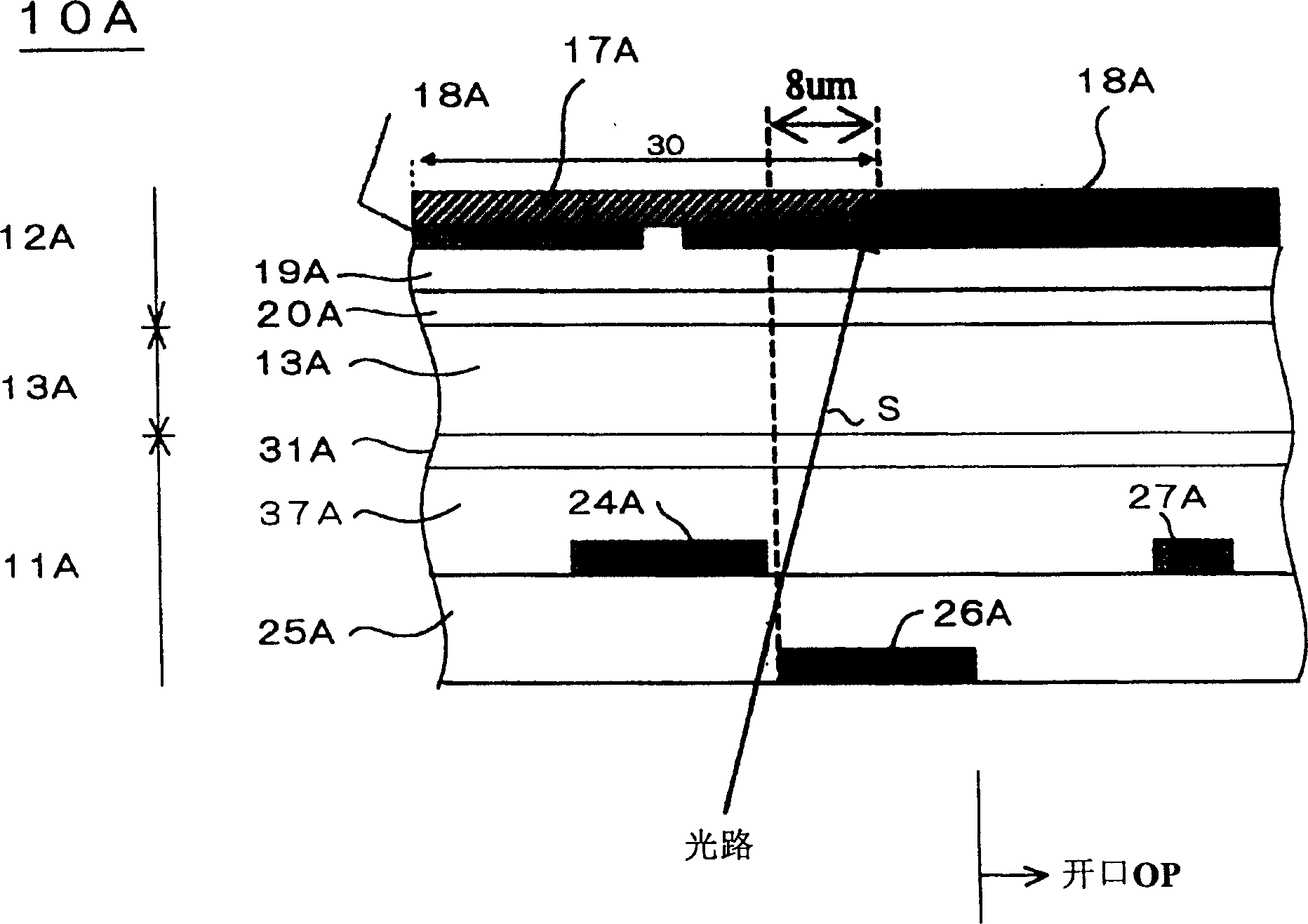

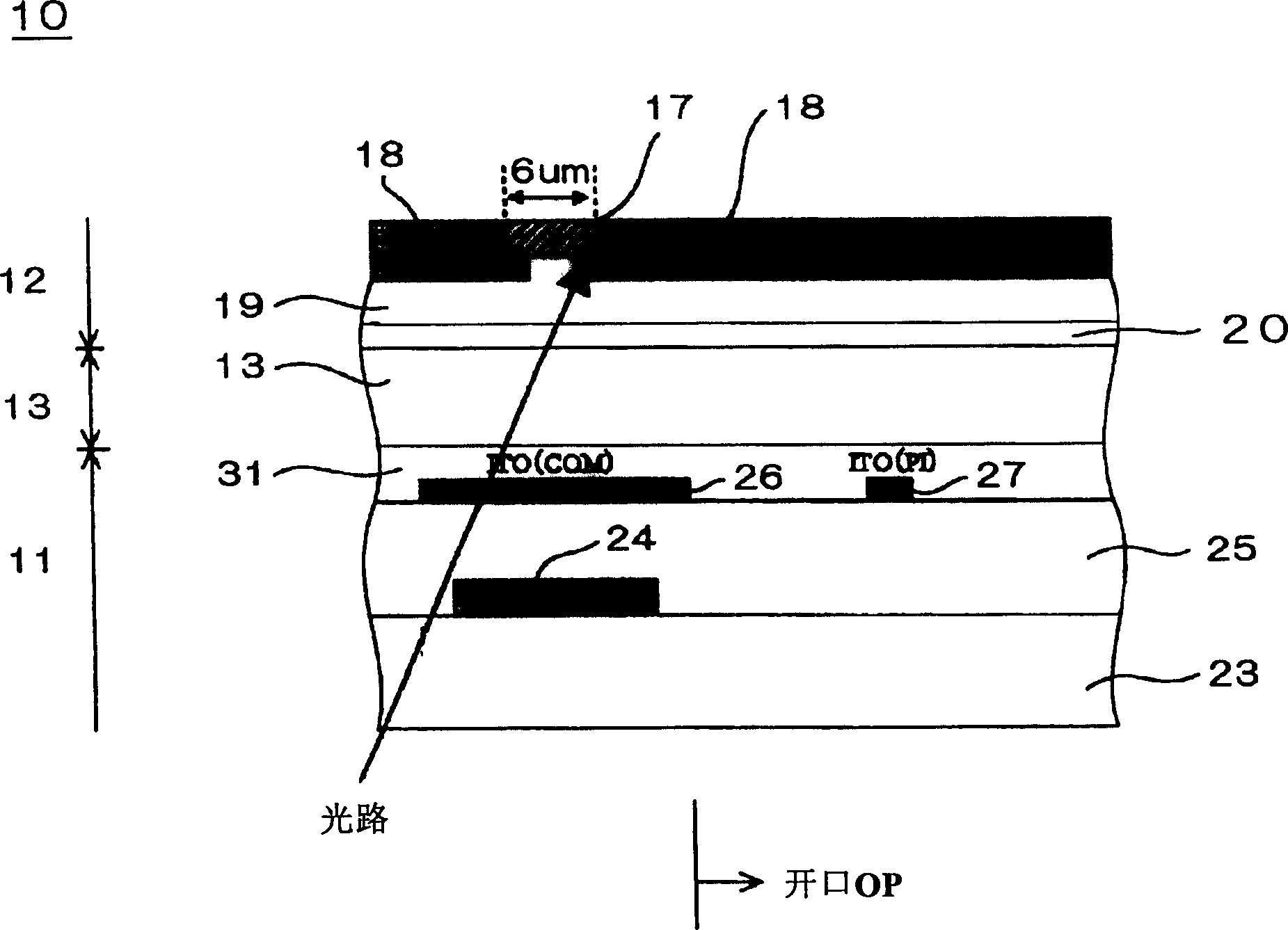

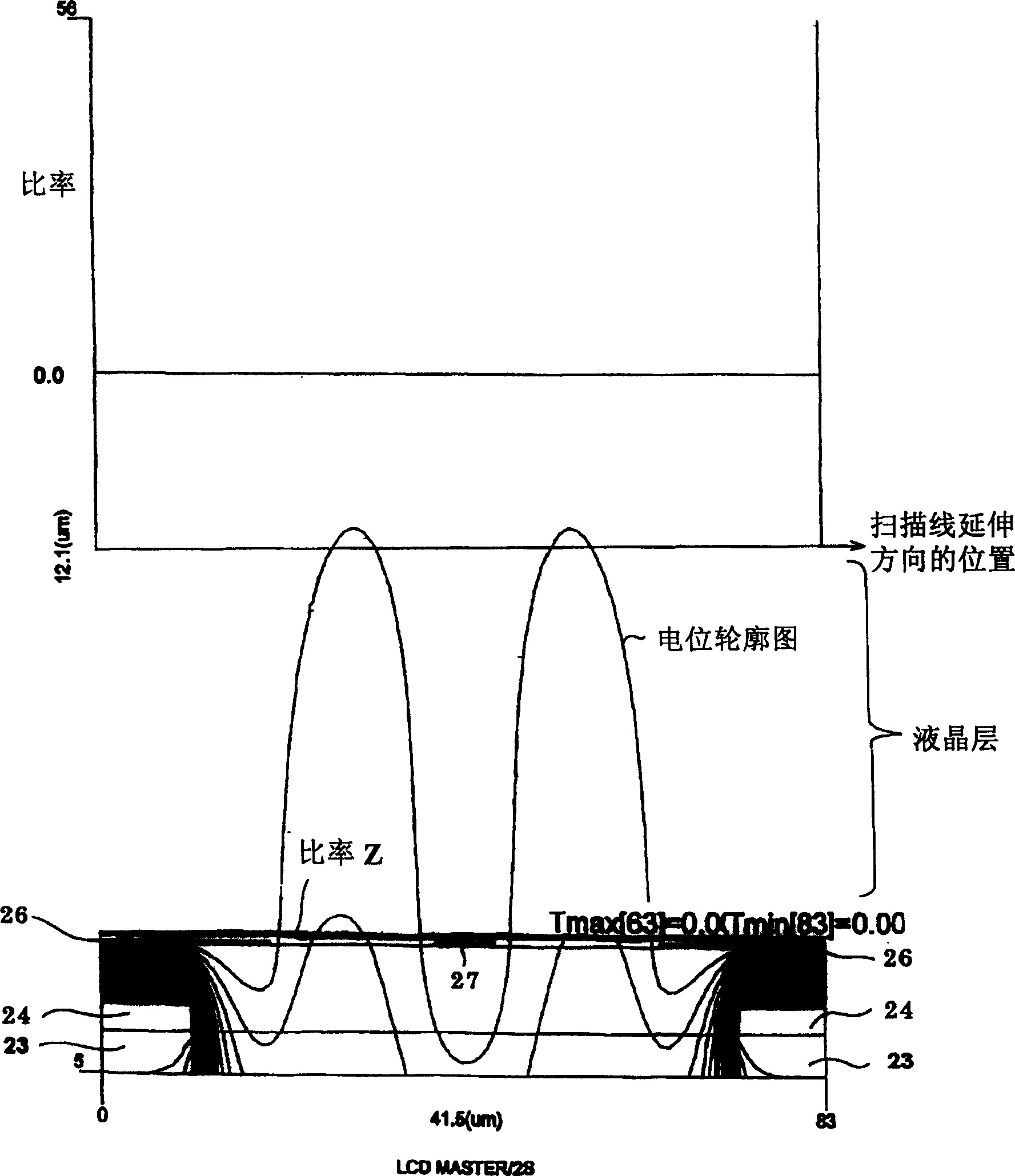

[0307] Figure 4 , 5 and 6 exemplify the planar switching mode active matrix type liquid crystal display device employed based on the first embodiment of the present invention. Figure 4 is a plan view of the liquid crystal display device 10 employed based on the first embodiment, Figure 5 is in Figure 4 The sectional view taken along the V-V line in the middle, and at the same time Image 6 is a circuit diagram of a unit pixel.

[0308] Such as Figure 5 As shown, the liquid crystal display device 10 is composed of an active device substrate 11 , an opposite substrate 12 and a liquid crystal layer 13 interposed between the active device substrate 11 and the opposite substrate 12 .

[0309] The opposing substrate 12 includes an electrically insulating transparent substrate 16, a black matrix layer 17 formed on the first surface of the electrically insulating transparent substrate 16 as an opaque film, and a colored layer formed on the first surface of the electrically i...

no. 1 example

[0430] 28A to 28K are sectional views of the liquid crystal display device 10 showing steps of a first example of the method of manufacturing the liquid crystal display device 10 including the second interlayer insulating film 25 having a multilayer structure of inorganic films and organic films.

[0431] First, as shown in FIG. 28A, a chromium layer as a first metal layer is formed on a glass substrate as an electrically insulating transparent substrate 22, and then, the chromium layer is made into a gate 30c and a common electrode by photolithography and dry etching. The pattern of lines 26a and 26b. Although only the common electrode line 26b is shown in FIGS. 28A to 30I, the common electrode line 26a will be described below together with the common electrode line 26b because the common electrode line 26a is formed together with the common electrode line 26b.

[0432] Then, as shown in FIG. 28B, a first interlayer insulating film 23 is formed over the entire transparent sub...

no. 2 example

[0443] 29A to 29I are cross-sectional views of the liquid crystal display device 10 showing steps of a second example of the method of manufacturing the liquid crystal display device 10 including the second interlayer insulating film 25 composed of a single organic film.

[0444] First, as shown in FIG. 29A, a chromium layer as a first metal layer is formed on a glass substrate as an electrically insulating transparent substrate 22, and then, the chromium layer is formed into a gate 30c and a common electrode by photolithography and dry etching. The pattern of lines 26a and 26b.

[0445] Then, as shown in FIG. 29B, the first interlayer insulating film 23 is formed over the entire transparent substrate 22, covering the gate electrode 30c and the common electrode lines 26a and 26b. The first interlayer insulating film 23 has a multilayer structure composed of a silicon dioxide (SiO2) film and a silicon nitride (SiNx) film.

[0446] Then, as shown in FIG. 29C , an amorphous sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com