Combine

A combine harvester, harvesting section technology, applied in the direction of harvesters, cutters, chassis of agricultural machinery, etc., can solve the problems of pre-dust collector damage, difficult cooling air dust removal, storage or truck transportation restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

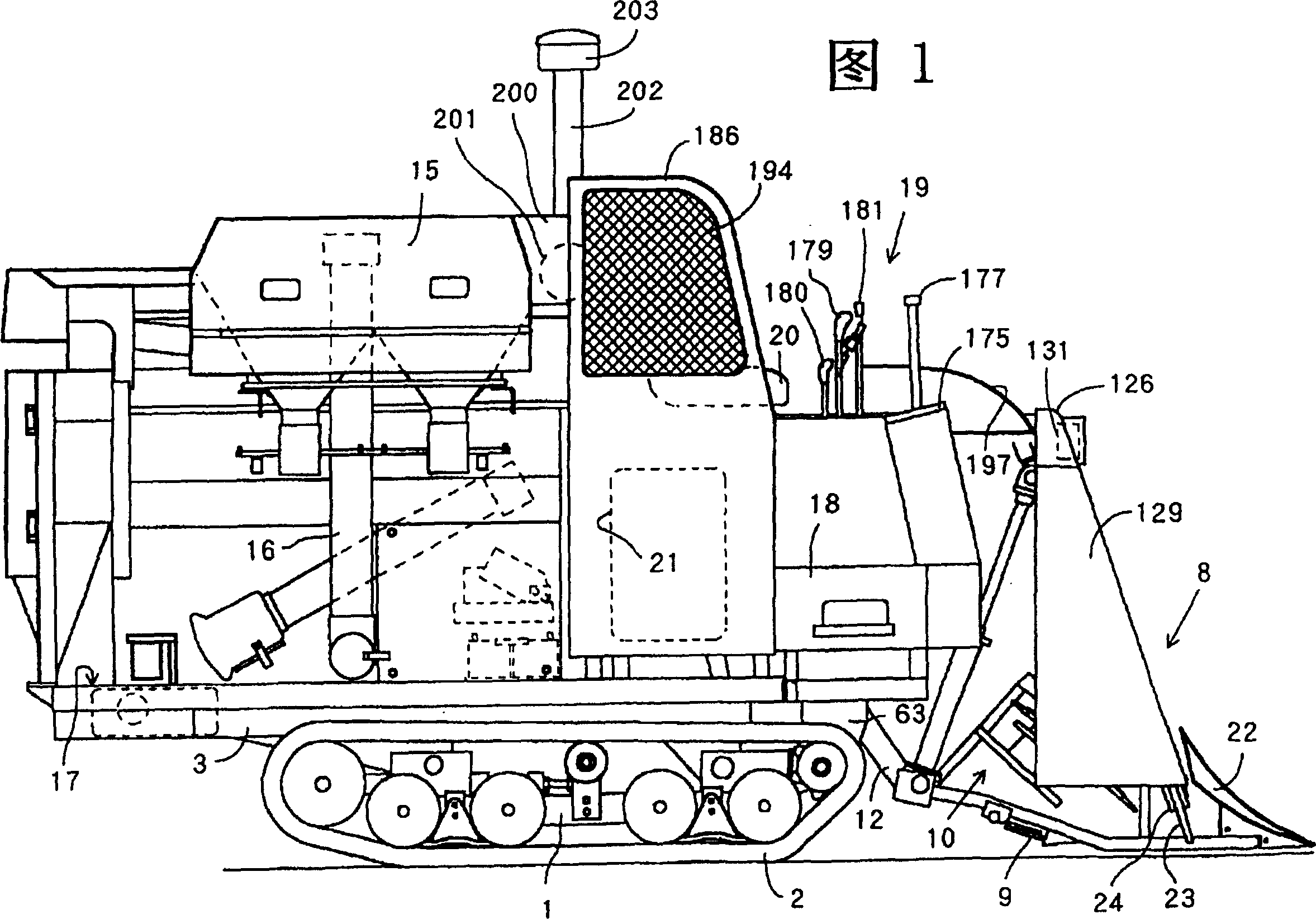

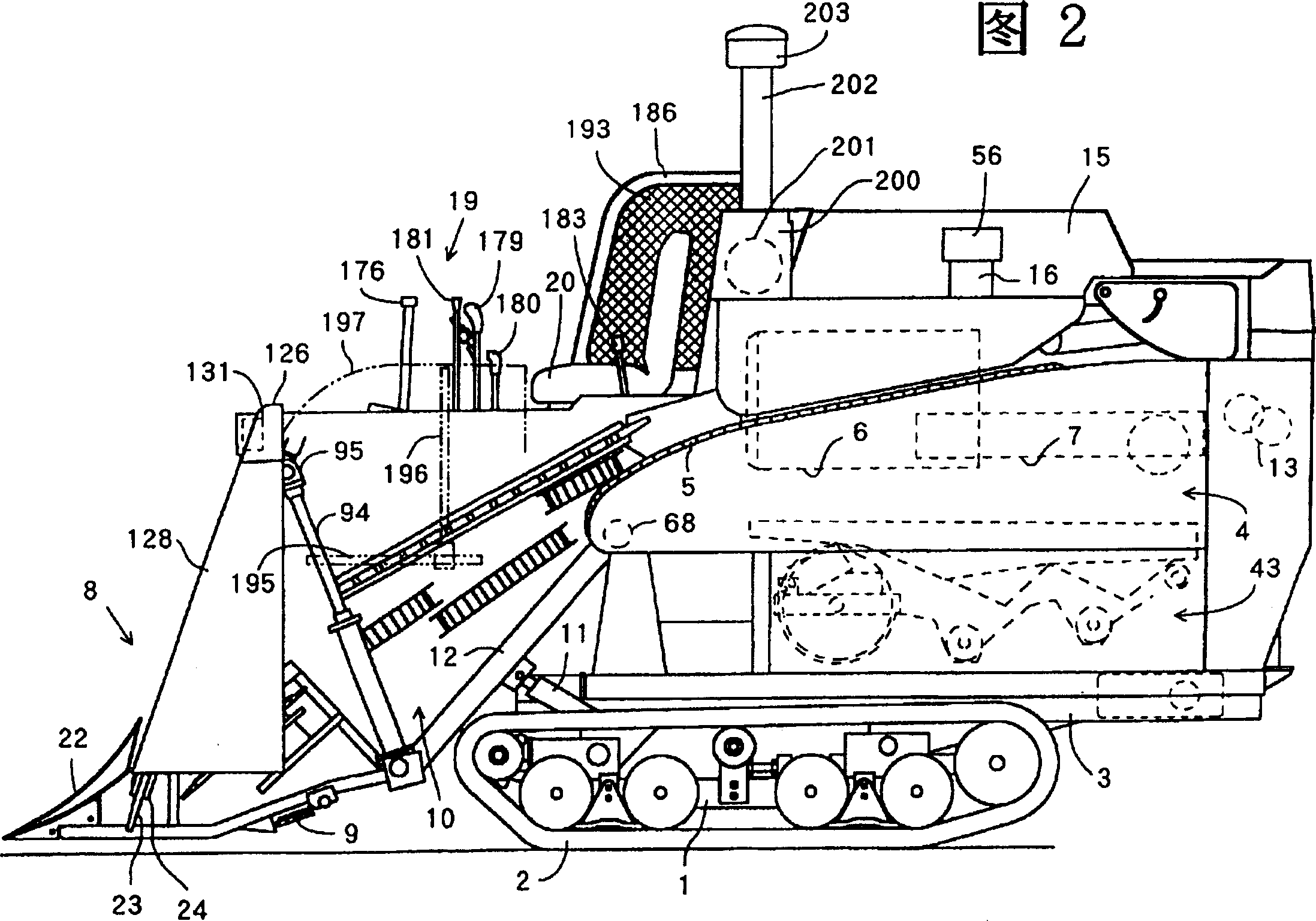

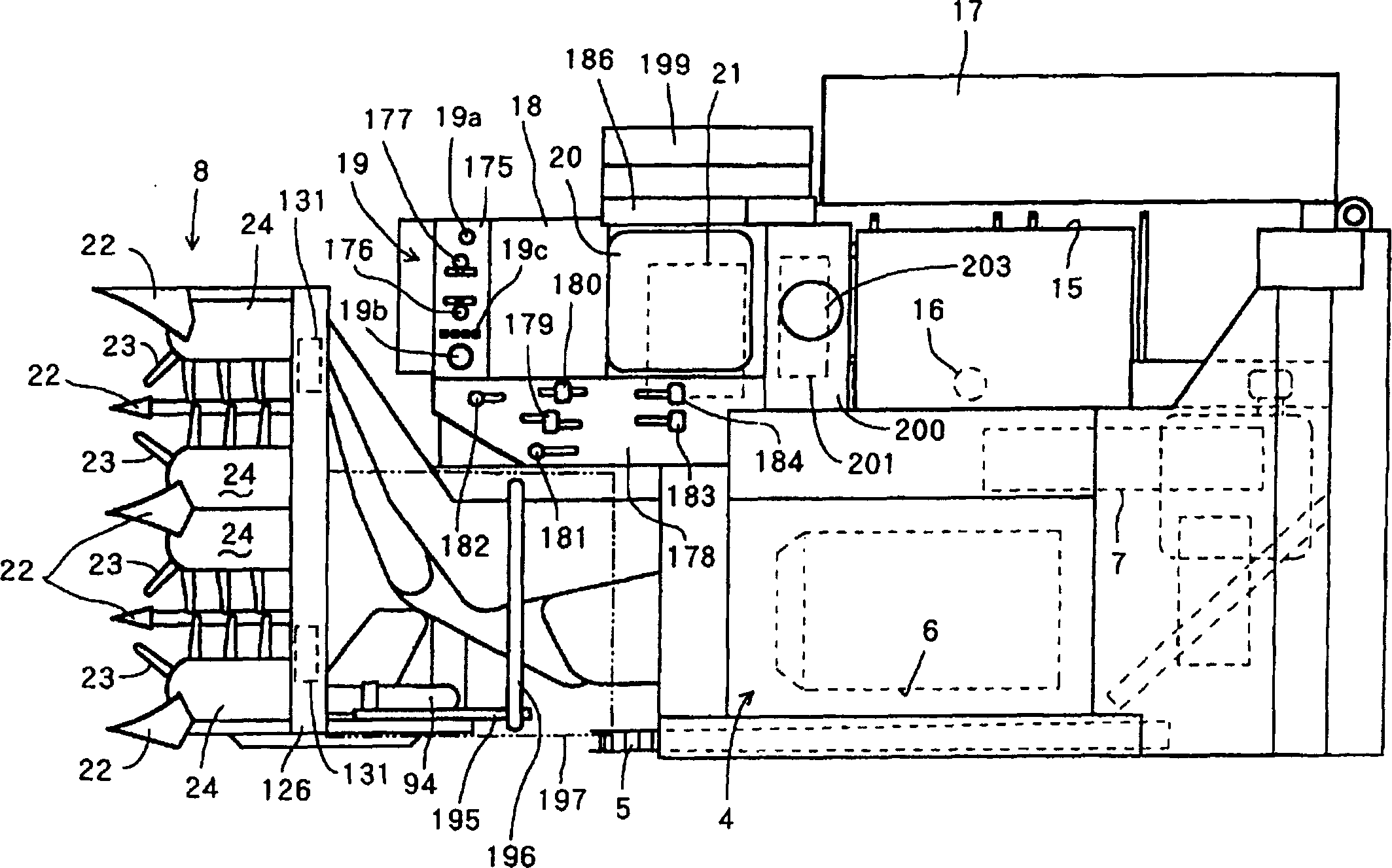

[0044] Embodiments of the present invention will be described below with reference to the drawings. Fig. 1 is a right side view of the combine harvester. Fig. 2 is a left side view of the combine shown in Fig. 1 . image 3 It is a plan view of the combine harvester shown in Fig. 1 . 1 among the figure is the crawler frame that left and right pair of walking track 2,2 are housed, and 3 is the machine platform that is erected on crawler frame 1 upper side. 4 is the threshing part where the feed chain 5 is stretched on the left side and the threshing drum 6 and the processing drum 7 are set inside. 8 is the reaping section for 4 row reaping equipped with cutting blade 9 and grain stalk conveying mechanism 10 etc. 11 is the oil pressure lift cylinder that harvesting section 8 is lifted by harvesting frame 12. The 13th, face the grass discharge cutter of the grass discharge chain 14 terminals. 15 is the grain box which carries in the grain from the threshing part 4 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com