High-efficient electric desalting apparatus

An electrical desalination and equipment technology, applied in the direction of electricity/magnetic dehydration/demulsification, etc., can solve the problems of increased power consumption, poor dehydration effect, large power consumption, etc. Current adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

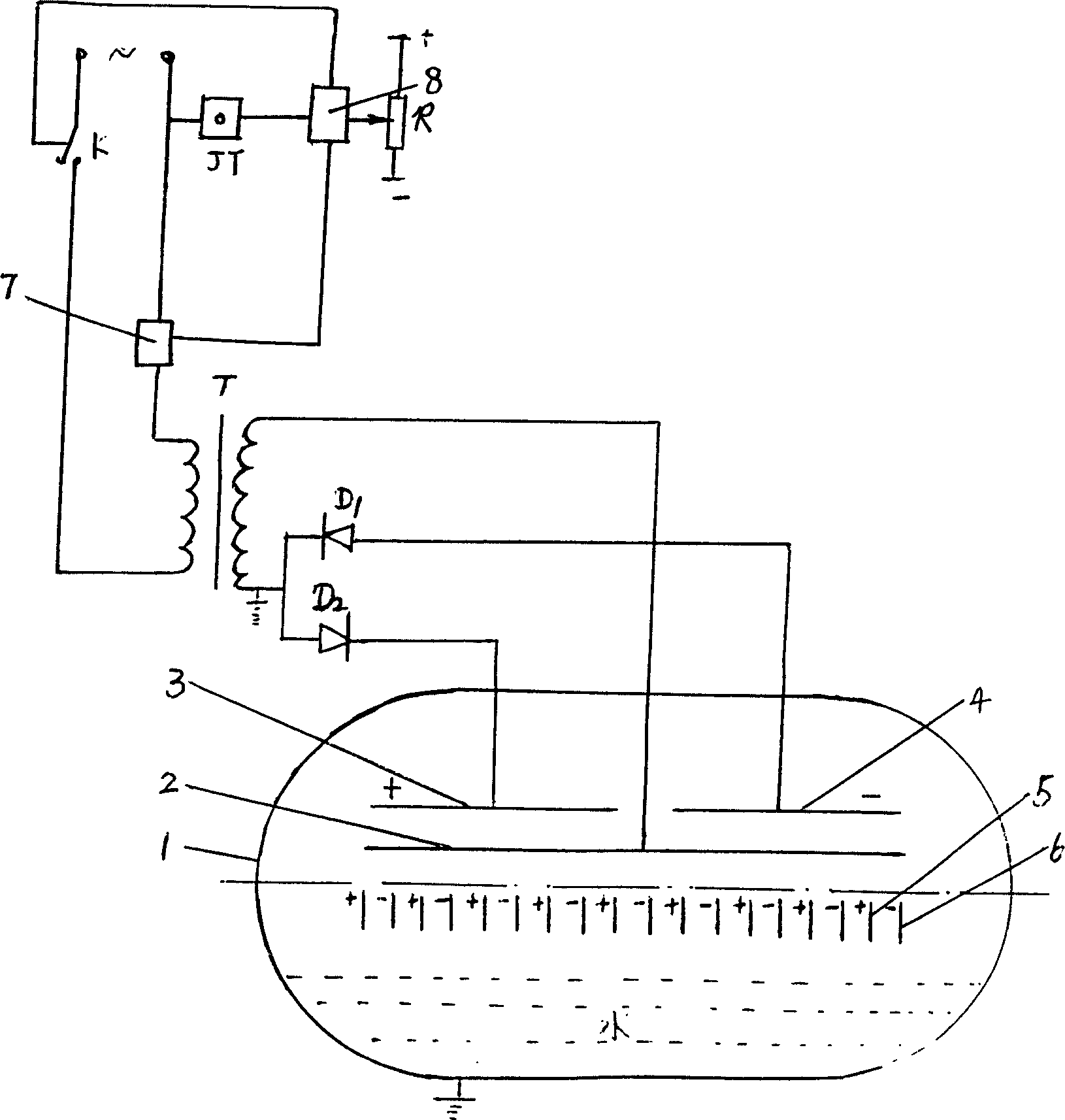

[0017] as attached image 3 shown.

[0018] exist image 3 , the horizontal large plate 2 in the electric desalination tank 1 is connected to the secondary output terminal of the transformer T, the unidirectional diodes D1 and D2 are connected to the secondary ground terminal of the transformer T, the thyristor switch 7, the AC contactor K and the transformer T The vertical positive plate 5 in the electric desalination tank 1 is connected with the horizontal positive plate 3 in the electric desalination tank 1, and the vertical negative plate 6 in the electric desalination tank 1 is connected with the horizontal negative plate 4 in the electric desalination tank 1 . The working current is set through the adjustable resistor R, when the working current reaches or exceeds the set current, the Hall current sensor JT in the circuit outputs the current driving circuit 8 to work to make the thyristor switch 7 and the AC contactor K act, cut off the power supply, and protect The d...

Embodiment 2

[0020] as attached Figure 4 shown.

[0021] exist Figure 4 In the shown embodiment, the horizontal large plate 2 in the electric desalination tank 1 is connected to the secondary output terminal of the transformer T, the unidirectional diodes D1 and D2 are connected to the secondary ground terminal of the transformer T, and the thyristor JZG (the specific model is MTXD600A, the same below) and AC contactor K2 are connected to the primary coil of transformer T, the vertical positive plate 5 in the electric desalination tank 1 is connected to the horizontal positive plate 3 in the electric desalination tank 1, and the vertical negative plate in the electric desalination tank 1 6 is connected with the horizontal negative plate 4 in the electric desalination tank 1. The working current of the present invention is set in this way. Adjust the adjustable resistors R1 and R2 according to the needs to adjust the set current within the rated current range. When the actual current re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com