Device used for circular comb

A technology of circular comb and comb brush, applied in the field of circular comb devices, can solve problems such as damage of combing results, and achieve the effects of preventing excessive fiber damage, large length and good combing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

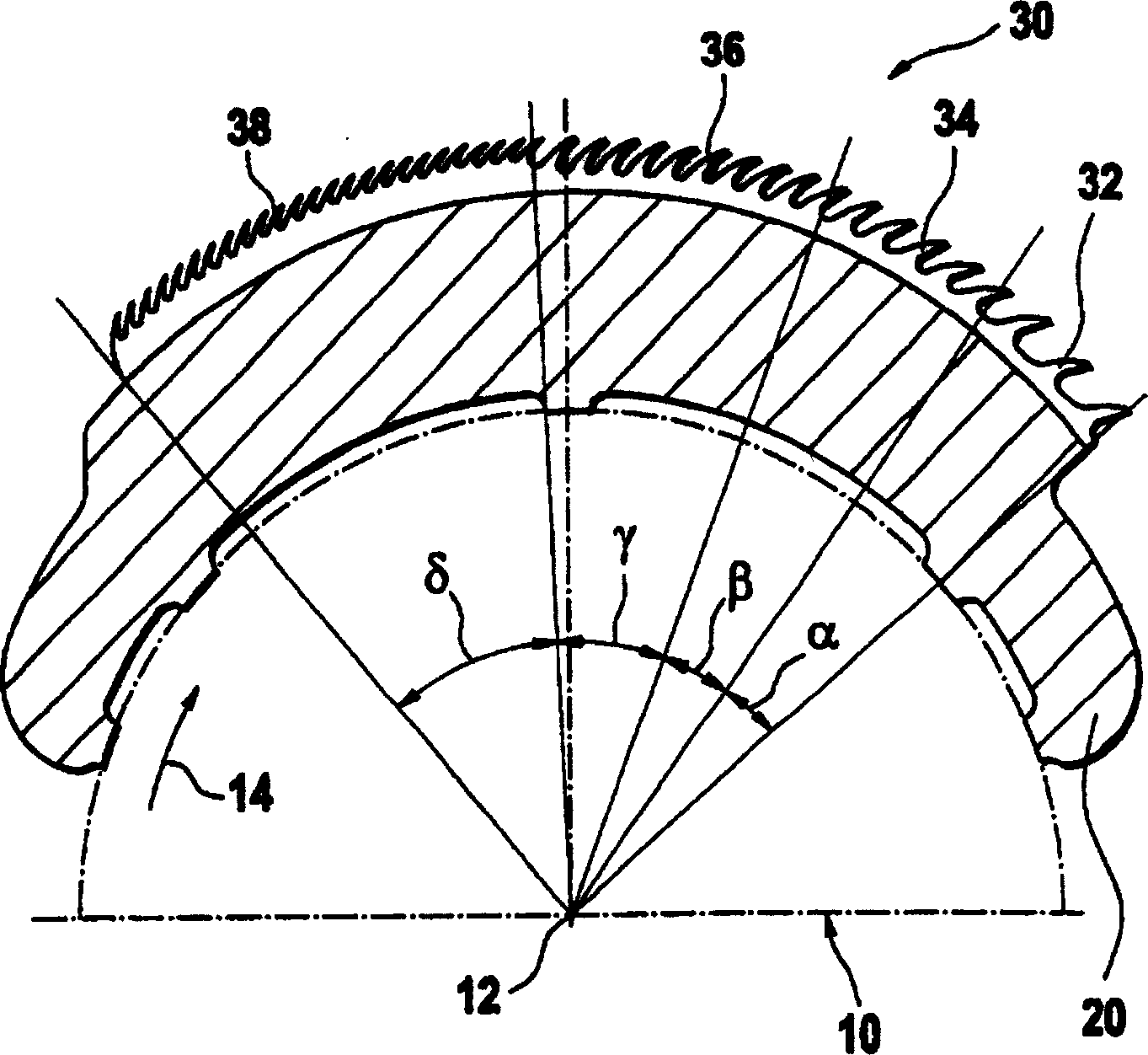

[0024] figure 1The illustrated circular comb comprises a substantially cylindrical support body 10, a base body 20, and an all-metal sawtooth combing device generally indicated at 30, the base body extending along the circumference of the cylindrical support body 10. Extending on a part of the outer surface of the base body 20 and expanding the latter in the radial direction, while the all-metal sawtooth combing device is arranged on the outer surface of the base body 20 . The entire structure including the carding device 30 , the base body 20 and the support body 10 is rotatable about the cylindrical axis 12 of the support body 10 as indicated by the arrow 14 . Combing device 30 comprises four combing segments 32, 34, 36 and 38 in total, and these combing segments follow one another on the circumferential direction, wherein combing segment 32, referred to as engaging segment hereinafter, when rotating along the direction shown by arrow 14 , first engage with the fiber pile t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com