Breaking-resistant vertical storehouse

An anti-breakage, silo body technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of reducing coal impact speed, difficult lump coal rate, and high cost, preventing lump coal from breaking, improving lump coal rate, operating handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

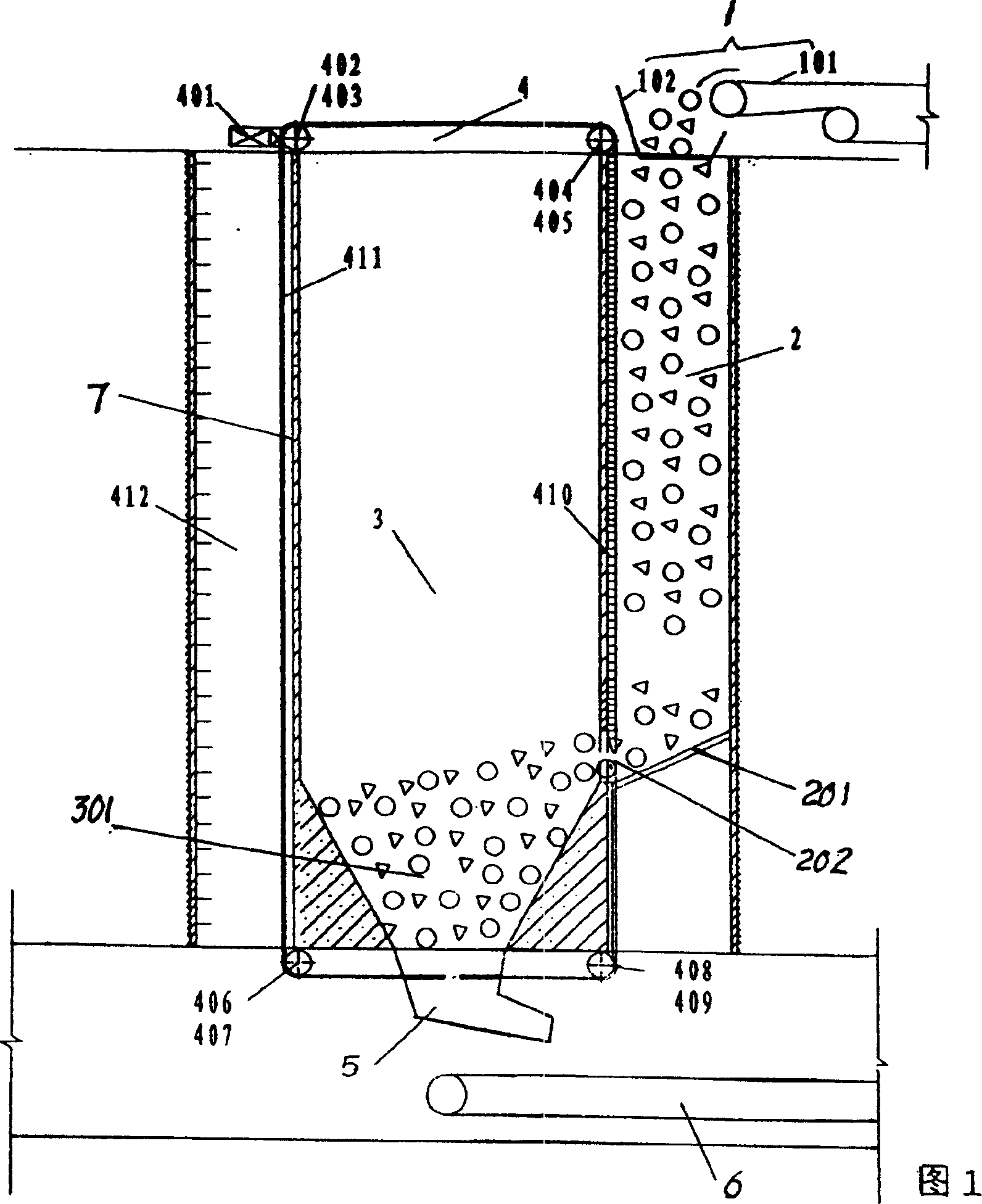

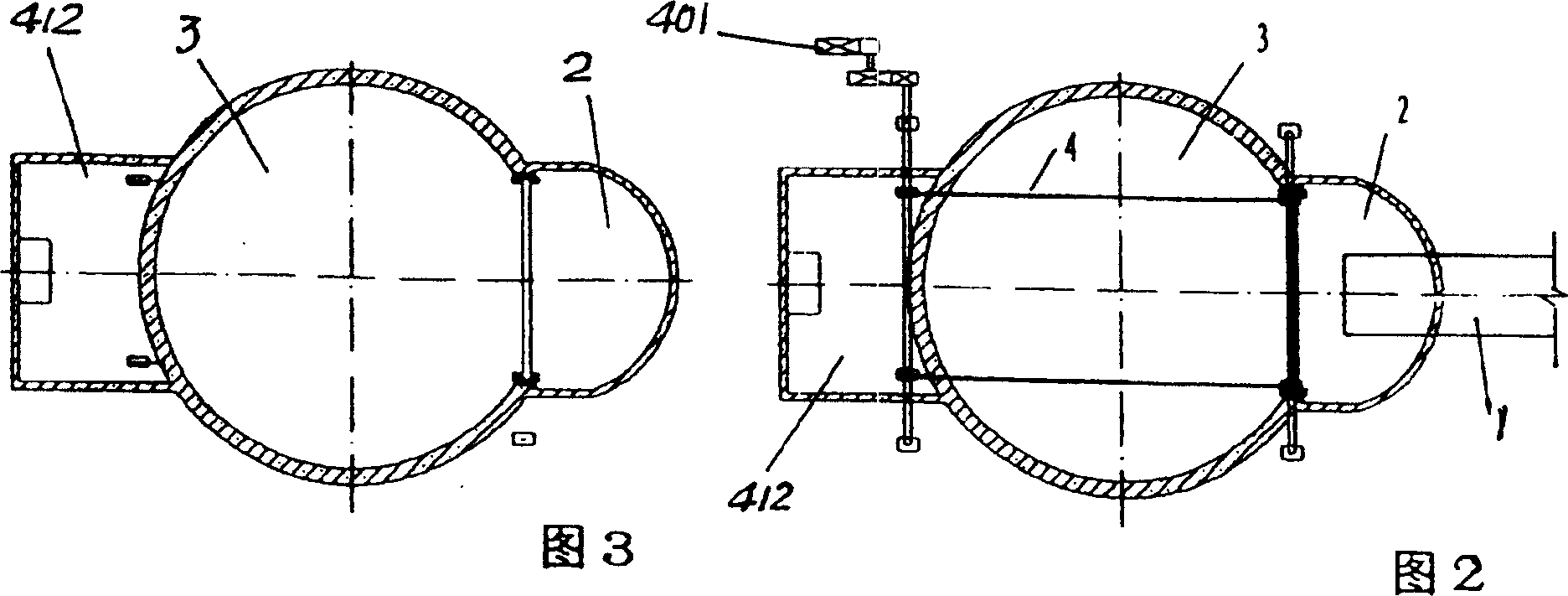

[0033] Please refer to Fig. 1, Fig. 2 and Fig. 3, the present invention is an anti-breakage vertical silo, including a power system, a conveyor, and a coal feeder;

[0034] The warehouse body is composed of the mother warehouse 3 and the sub-compartment 2 connected to both sides of the mother warehouse and the back curtain room 412; The end is aligned with the material inlet 202 of the mother warehouse 3, and the material inlet is connected to the funnel-shaped bottom chamber 301 of the mother warehouse 3. The lower outlet of the bottom chamber is connected to the coal feeder 5, and the lower part of the outlet of the coal feeder is provided with Conveyor 6,

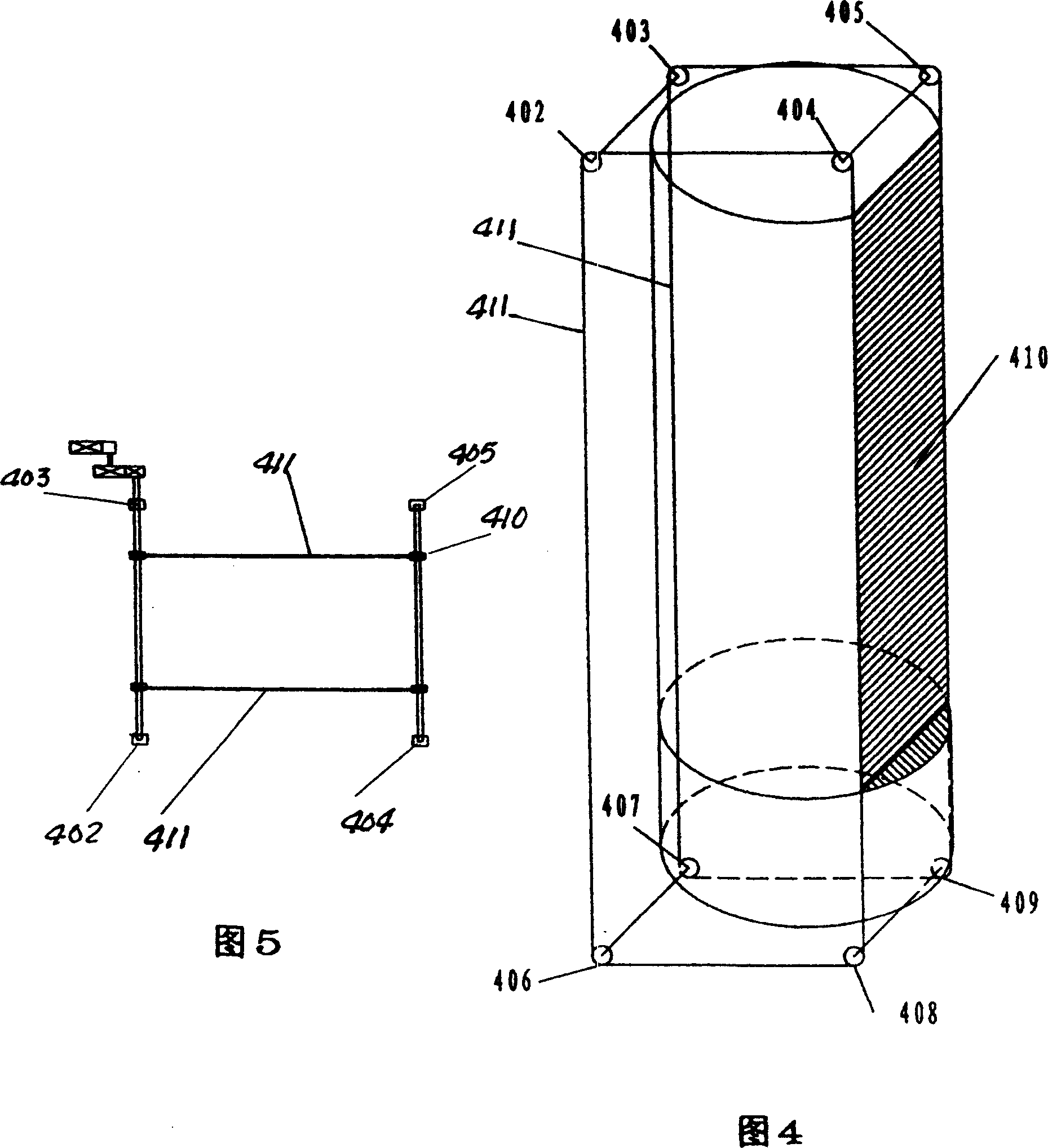

[0035] The structure of the curtain device 4 is as follows: a curtain 410 is arranged on the vertical wall of the sub-compartment 2 adjacent to the mother warehouse 3, and the material inlet 202 is opened or closed when the curtain is raised and lowered, and the upper and lower ends of the curtain are respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com