Structure for preventing centrifugal compressor from reverse rotation

A compressor, centrifugal technology, applied in mechanical equipment, machine/engine, pump control, etc., can solve the problem of component damage, reduce the first radial bearing 9A and the second radial bearing 9B, large noise, etc., to achieve The effect of improving overall longevity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

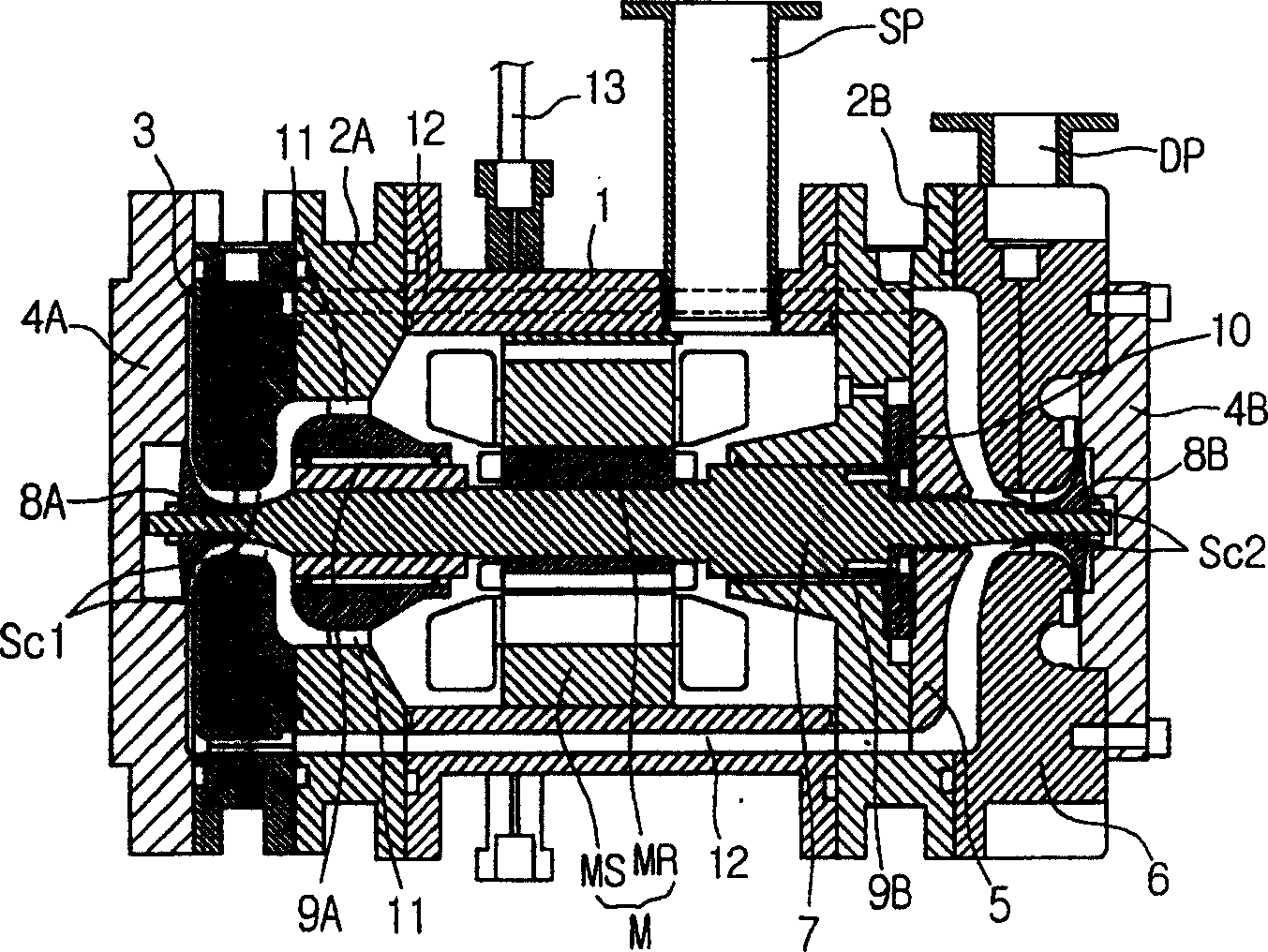

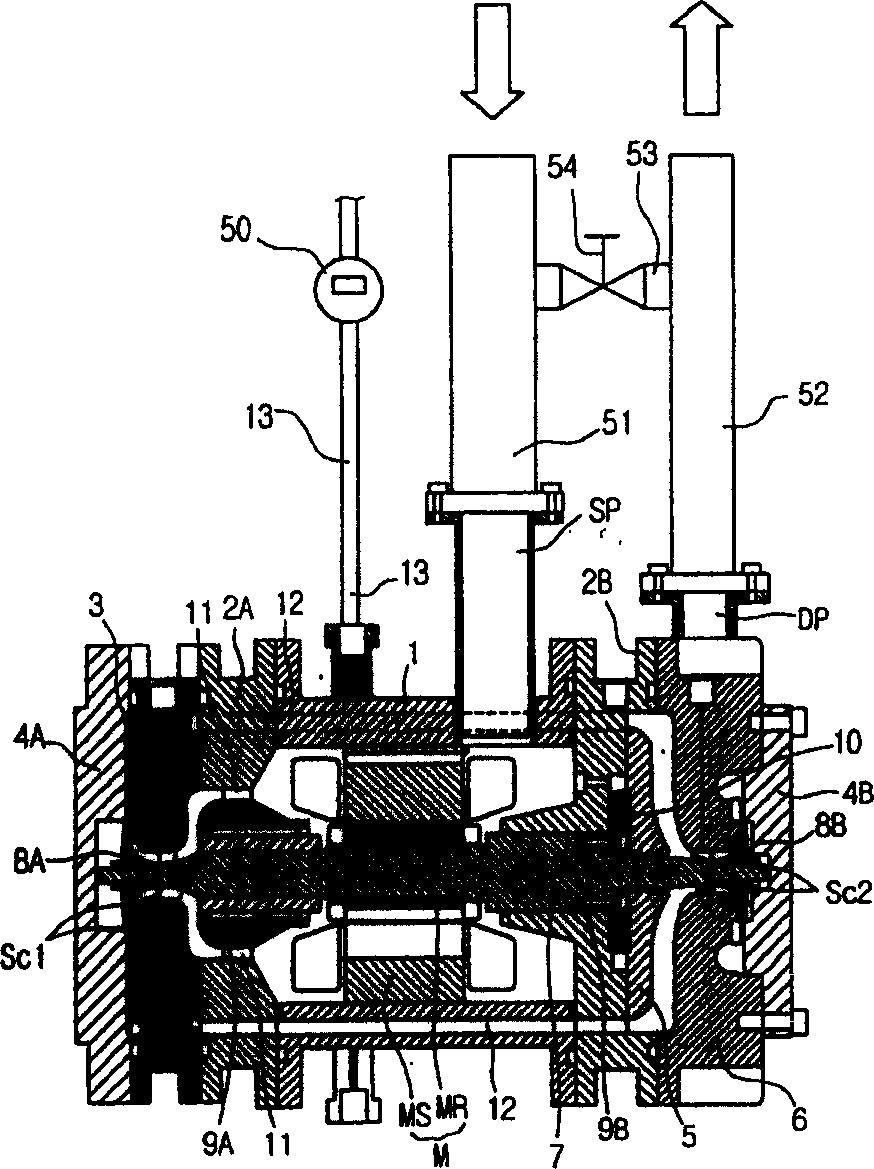

[0017] The structure for preventing reverse rotation of the centrifugal compressor of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

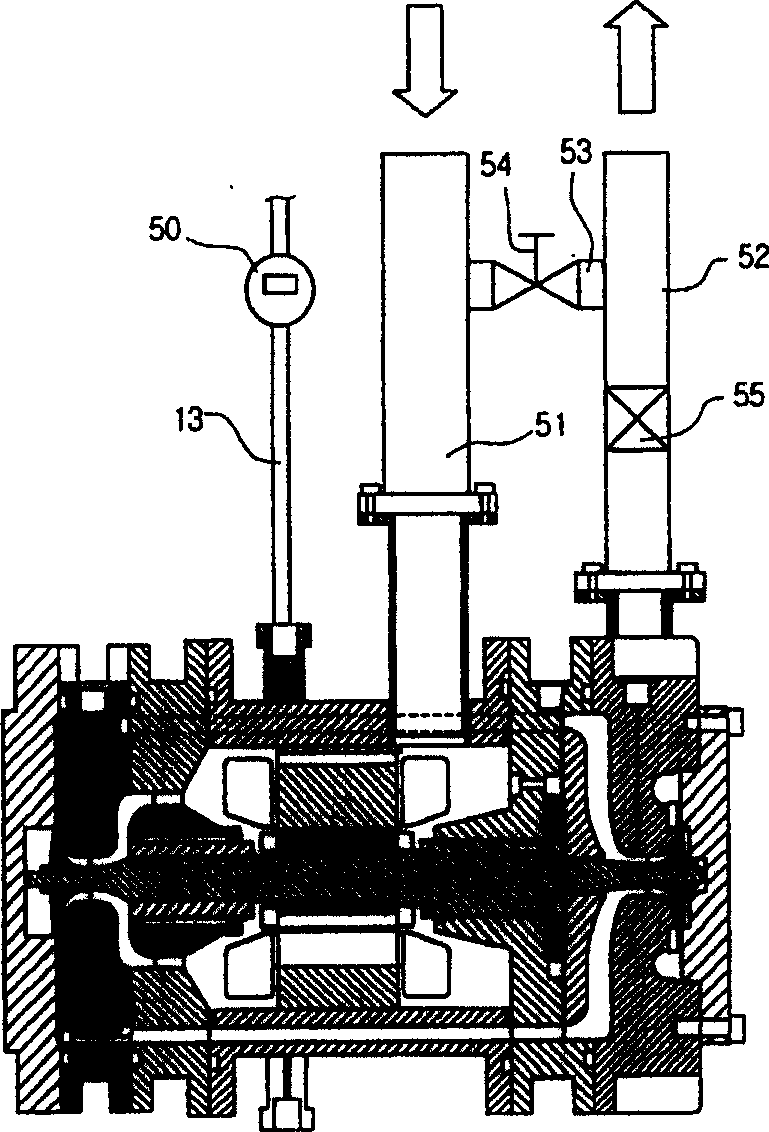

[0018] Such as figure 2 As shown, for the low-temperature and low-pressure medium that flows in through the suction port SP, it is compressed to a high-temperature and high-pressure state by the secondary compression and compression action of the primary compression impeller 8A and the secondary compression impeller 8B, and then discharged through the discharge port DP. , the structure of the compression part is the same as that of the prior art, the difference is that the suction pipe 51 is connected on the suction port SP of the compressor, the discharge pipe 52 is connected on the discharge port DP of the compressor, and the flow pipe with the diverter valve 54 is installed 53 is arranged between the suction pipe 51 and the discharge pipe 52, so that they com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com