Mucor mould for production of preserved beancurd

A technology of mucor and strains, applied in applications, fungi, food preparation, etc., can solve the problems of large human and material resources and disadvantages, and achieve the effects of improving quality, reducing labor intensity and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

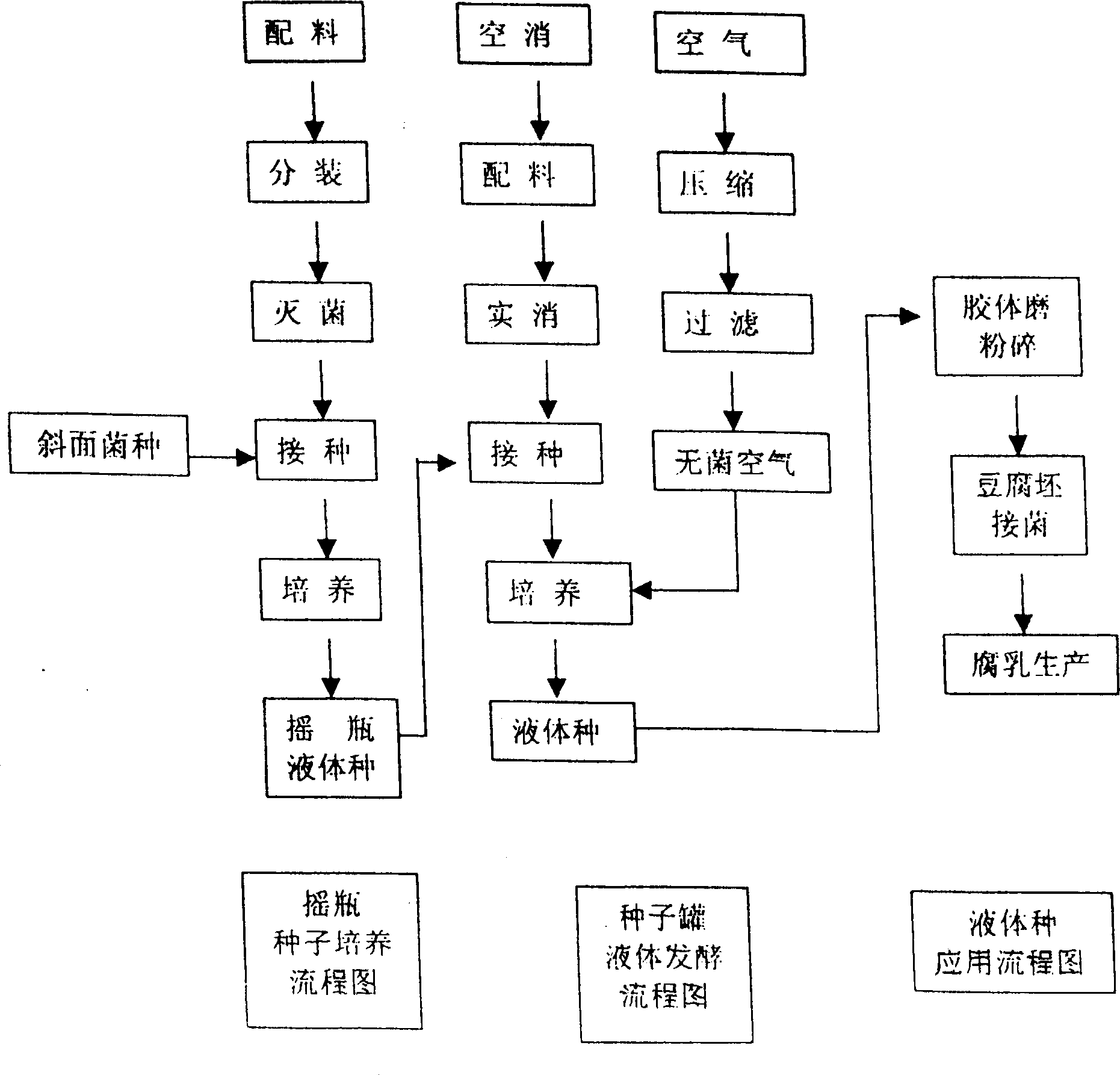

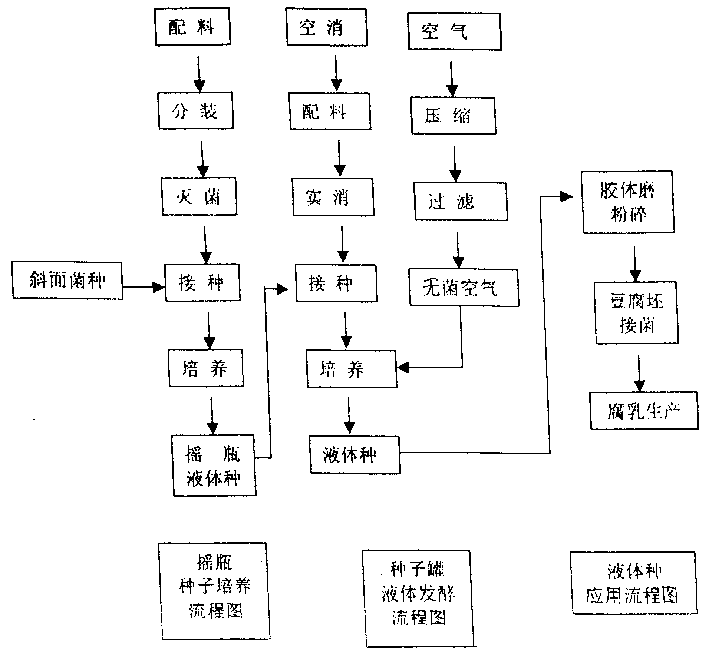

Image

Examples

Embodiment 1

[0025] a. Preparation of slant strains: activate the refrigerated slant strains and inoculate them on the slant medium, and cultivate them in an incubator at 25-28°C for 2-3 days until the slant is covered with hyphae. The slant medium is ordinary PDA Medium.

[0026] b. Shake flask seed culture: put 250ml of shake flask culture medium in a 500ml Erlenmeyer flask, sterilize at 121°C for 30 minutes, and then cool to room temperature. Insert fresh slant strains about 1cm under sterile conditions 2 , cultivated on a shaking table at 28°C for 40 hours, the shaking table was reciprocating, and the rotating speed was 180rpm. After the cultivation was completed and confirmed that it was free of bacteria contamination, it was poured into an inoculation bottle under aseptic conditions for subsequent use.

[0027] The ingredients of the shake flask culture medium are: 35% of soybean milk, 0.1% of magnesium sulfate, 0.2% of potassium dihydrogen phosphate, 0.1% of yeast extract, constant...

Embodiment 2

[0032] a. Preparation of slant strains: activate the refrigerated slant strains and inoculate them on the slant medium, and cultivate them in an incubator at 25-28°C for 2-3 days until the slant is covered with hyphae. The slant medium is ordinary PDA Medium.

[0033] b. Shake flask seed culture: put 500ml shake flask culture medium in a 1000ml Erlenmeyer flask, sterilize at 121°C for 30 minutes, then cool to room temperature. Insert fresh slant strains about 2cm under aseptic conditions 2 , cultivated on a shaking table at 25°C for 30 hours, the shaking table was a reciprocating type, and the rotating speed was 150rpm. After the cultivation was completed and it was confirmed that there was no bacterial contamination, it was poured into an inoculation bottle under aseptic conditions for subsequent use.

[0034] The ingredients of the shake flask culture medium are: 20% soybean milk, 0.3% magnesium sulfate, 0.1% potassium dihydrogen phosphate, 0.5% yeast extract, constant volu...

Embodiment 3

[0039] a. Preparation of slant strains: activate the refrigerated slant strains and inoculate them on the slant medium, and cultivate them in an incubator at 25-28°C for 2-3 days until the slant is covered with hyphae. The slant medium is ordinary PDA Medium.

[0040] b. Shake flask seed culture: put 250ml of shake flask culture medium in a 500ml Erlenmeyer flask, sterilize at 121°C for 30 minutes, and then cool to room temperature. Insert fresh slant strains about 1cm under sterile conditions 2 , cultivated on a shaking table at 28°C for 24 hours, the shaking table was reciprocating, and the rotating speed was 200rpm. After the end of the cultivation, it was confirmed that there was no bacterial contamination, and it was poured into an inoculation bottle under aseptic conditions for subsequent use.

[0041] The ingredients of the shake flask culture medium are: 20% soybean milk, 0.2% magnesium sulfate, 0.3% potassium dihydrogen phosphate, 0.3% yeast extract, constant volume ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap