Filter device

A filter and filter cartridge technology, applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of cost increase, troublesome replacement of filter cartridges, etc., to reduce production costs and benefit Ease of assembly and rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to clarify the present invention more specifically, the specific structure of the filter device of the present invention will be described in detail below with reference to the accompanying drawings.

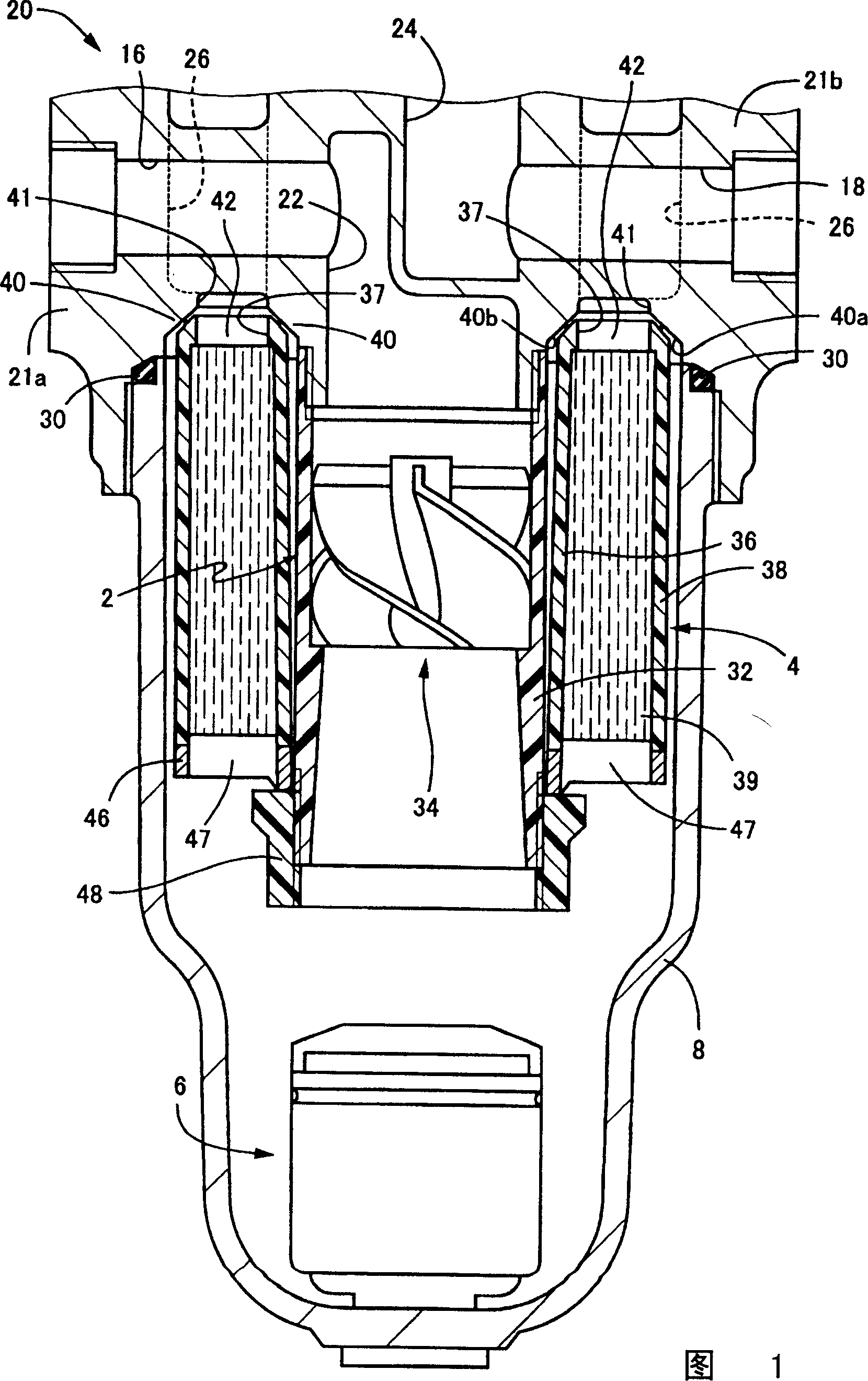

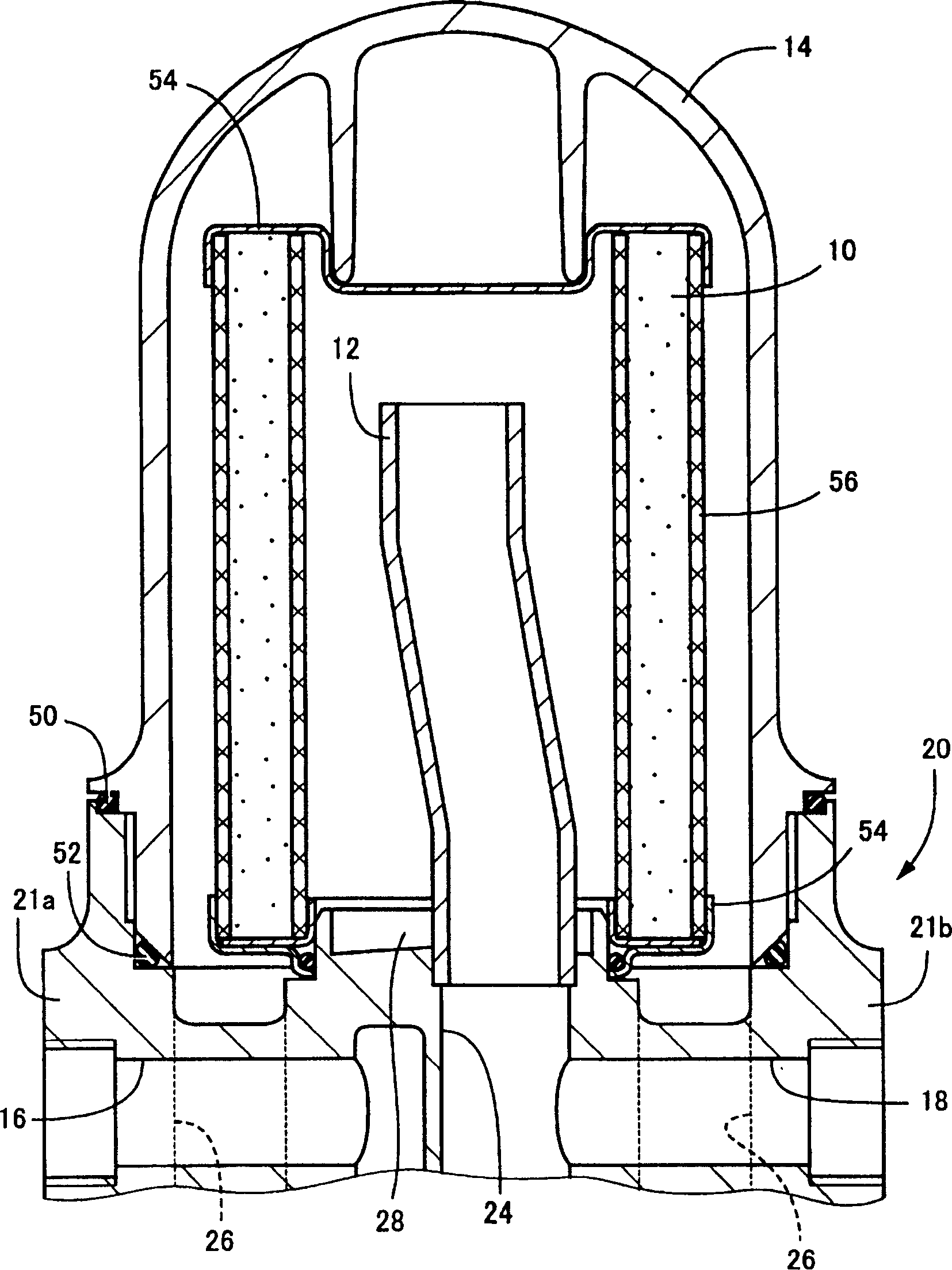

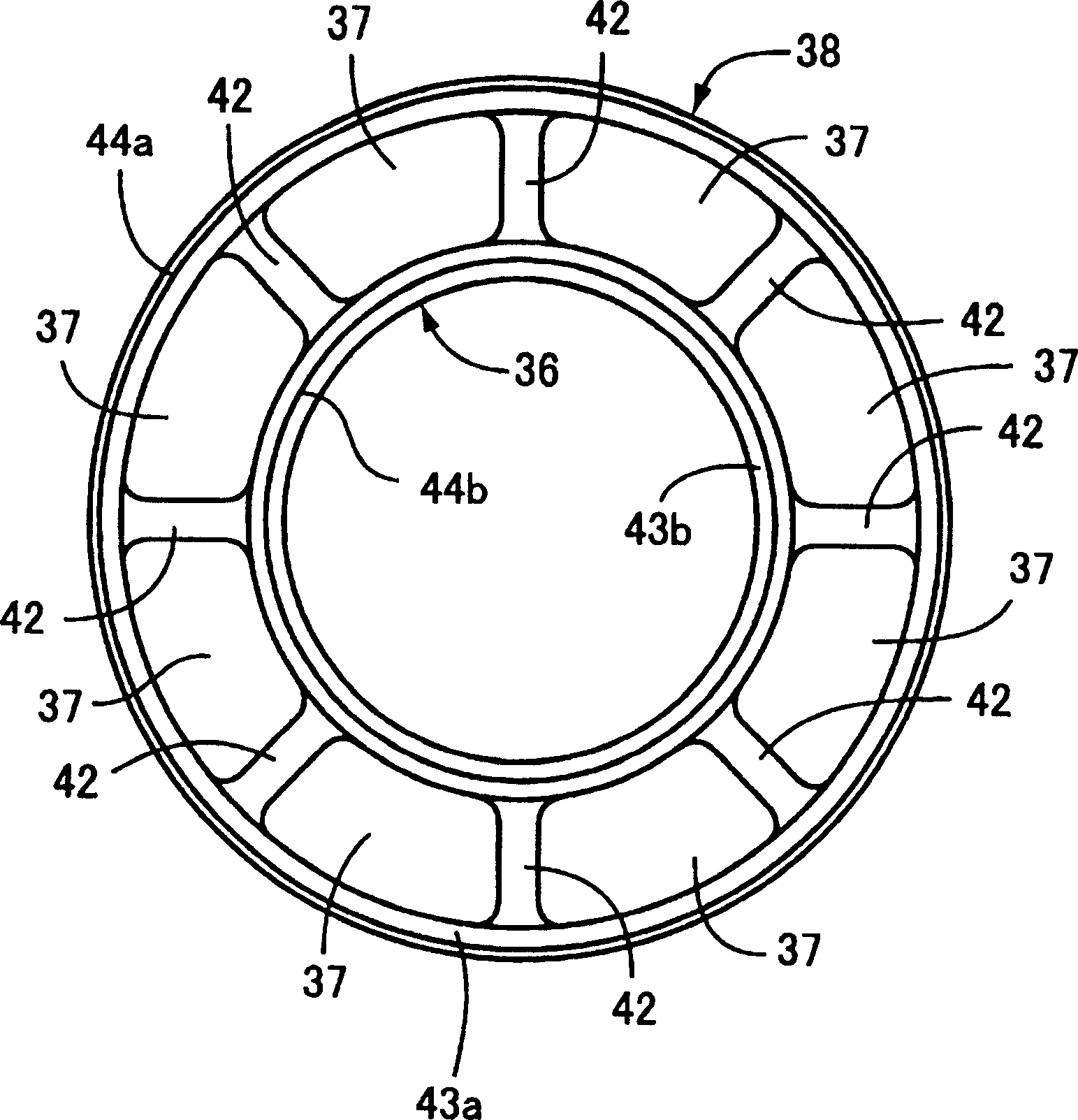

[0023] Figure 1 and figure 2 A specific example of introducing the structure of the present invention into the filter device for compressed air shown in Japanese Patent Application Laid-Open No. Hei 5-317630, Fig. 1 and figure 2 locally represent its lower and upper halves, respectively. Moreover, in these figures, this filter device consists of a lower housing 8 (refer to FIG. 1 ), an upper housing 14 (refer to figure 2) and a spacer member 20; the first filter cartridge 2, the second filter cartridge 4 and the discharge device 6 are accommodated in the lower housing 8, and the mist filter 10 and collector are accommodated in the upper housing 14. The air cylinder 12 and the above-mentioned spacer member 20 are arranged in the middle position between the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com