Terminal structure of electric cable and treating method thereof

A technology of end structure and end treatment, applied in the direction of coaxial cable/analog cable, cable terminal, electrical components, etc., can solve the problems of differential transmission signal line characteristic impedance mismatch, multiple working hours and cost, signal reflection, etc. , to achieve low cost, reduce reflection, and achieve the effect of impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

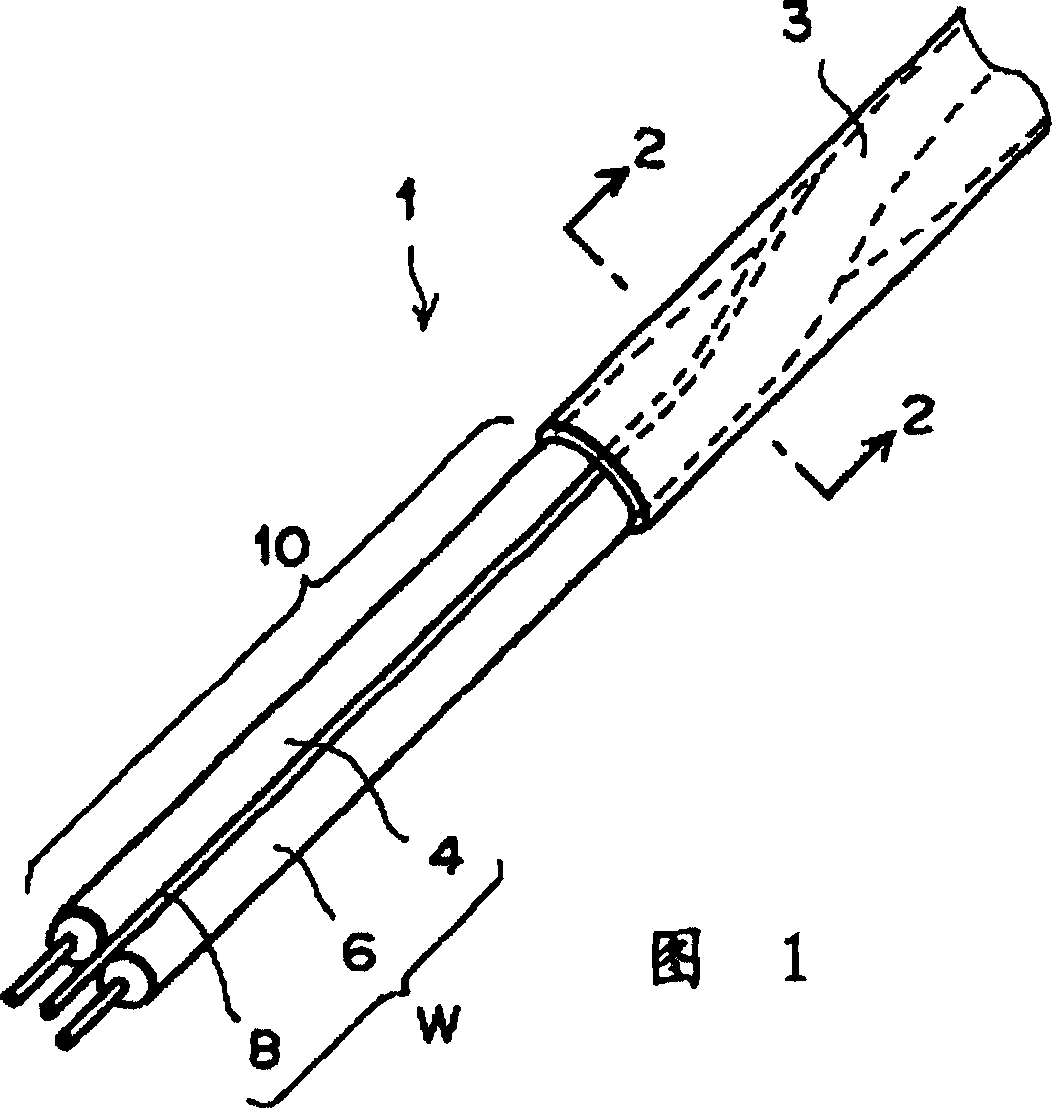

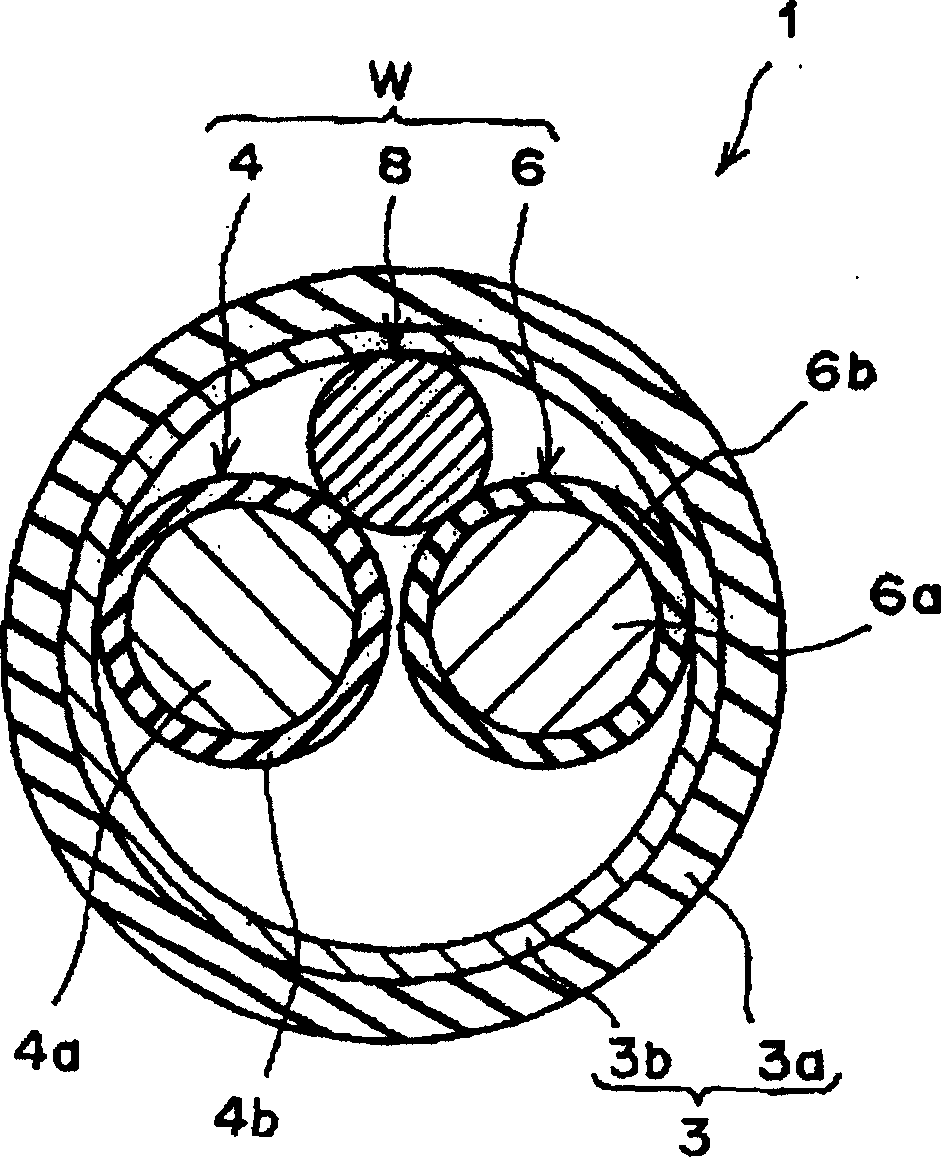

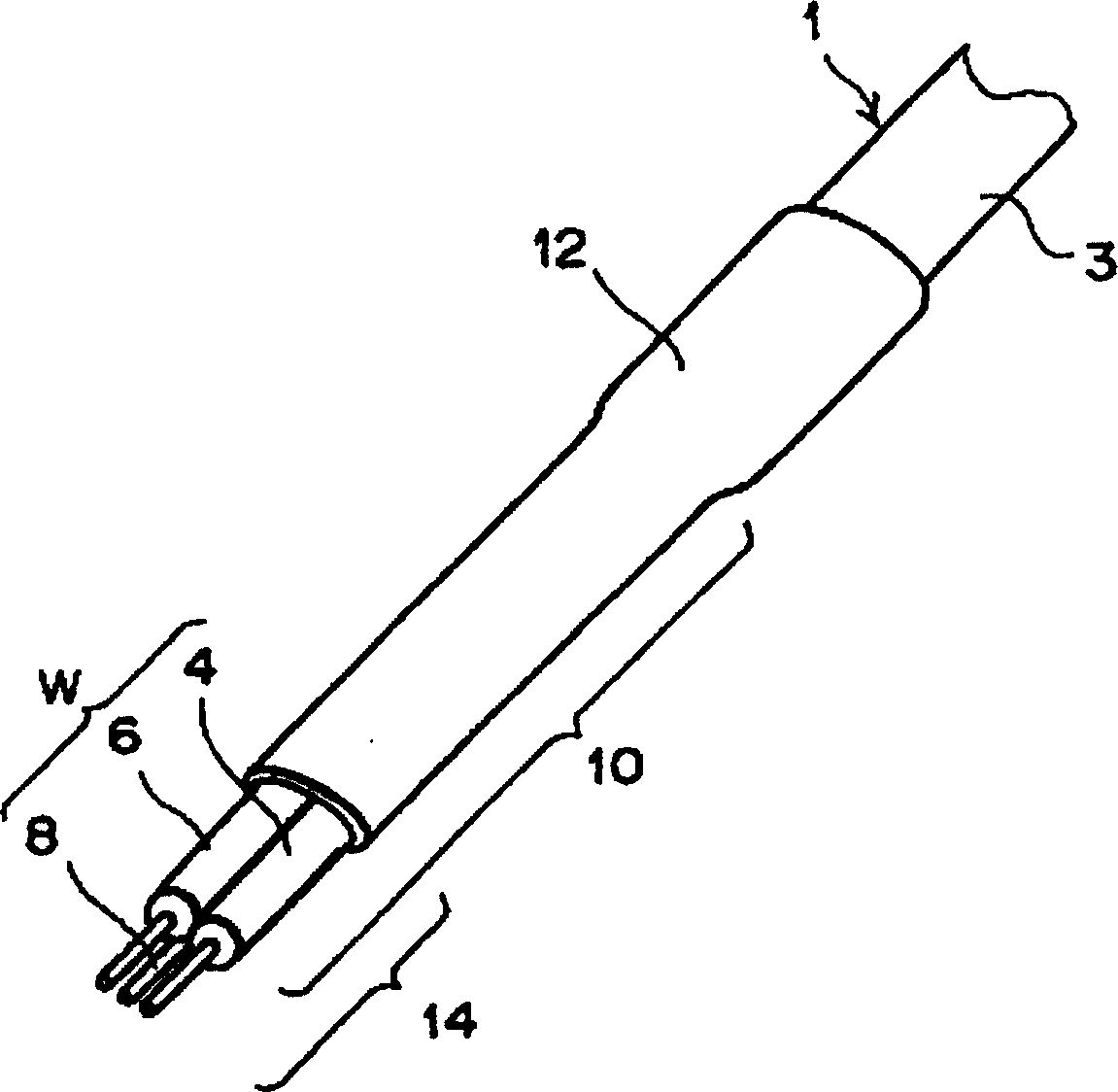

[0022] Below, the best implementation forms of the cable end structure and the electric cable end treatment method of the present invention will be described in detail with reference to the accompanying drawings.

[0023] Fig. 1 is a perspective view of an end portion of an electric cable (hereinafter simply referred to as a cable) adopting the cable end structure of the present invention, showing the condition after part of the shielding coating is stripped off. figure 2 It is a 2-2 cross-sectional view of the cable showing a cross-section taken along the 2-2 line at the end of the cable shown in FIG. 1 . image 3 It is the perspective view similar to FIG. 1 after the end part of the cable shown in FIG. 1 is tightly covered with the heat-shrinkable tube.

[0024] Below, combined with Figure 1 to image 3 Be explained. As shown in FIG. 1 , generally, the cable 1 is a cable of the type called "shielded twisted pair cable" suitable for high-speed digital differential transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com