Conic portion and neck sealing body for projecting tube

A sealing body and cone technology, applied in the sealing body field, can solve the problems of reducing the applied accelerating voltage, reducing the luminous brightness of the phosphor, and degrading the image quality, and achieving the effect of suppressing the deflection electric power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Refer below Figure 1 to Figure 6 , to illustrate the embodiments of the present invention.

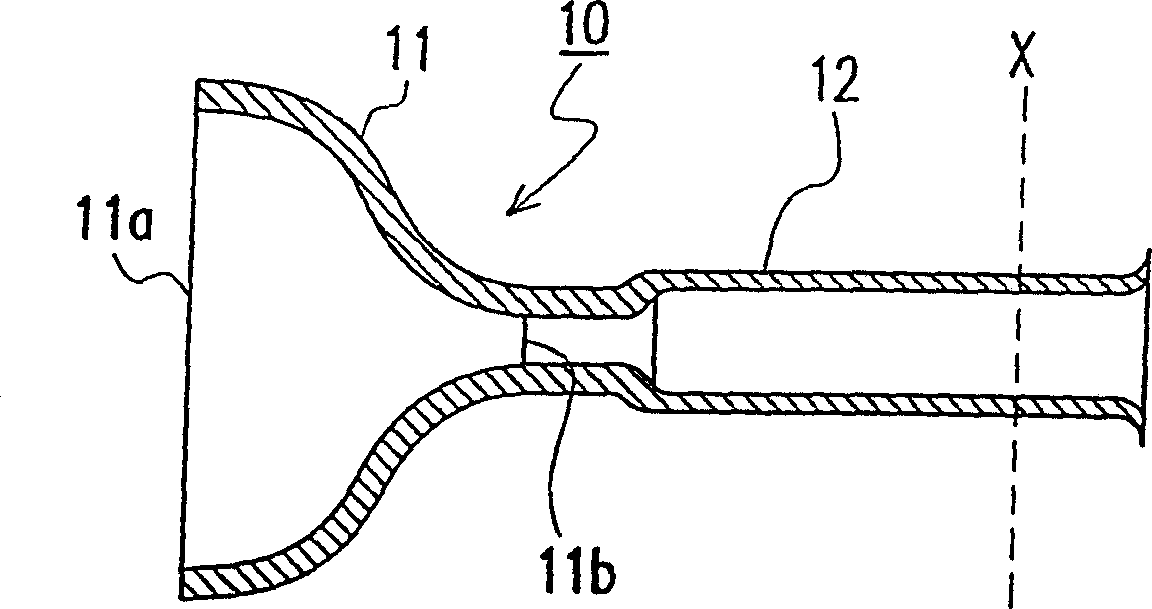

[0026] The composition of the projection tube cone and the neck sealing body 10 includes: a funnel-shaped cone 11 with a substantially rectangular large opening 11a and a circular small opening 11b; A cylindrical neck tube 12 .

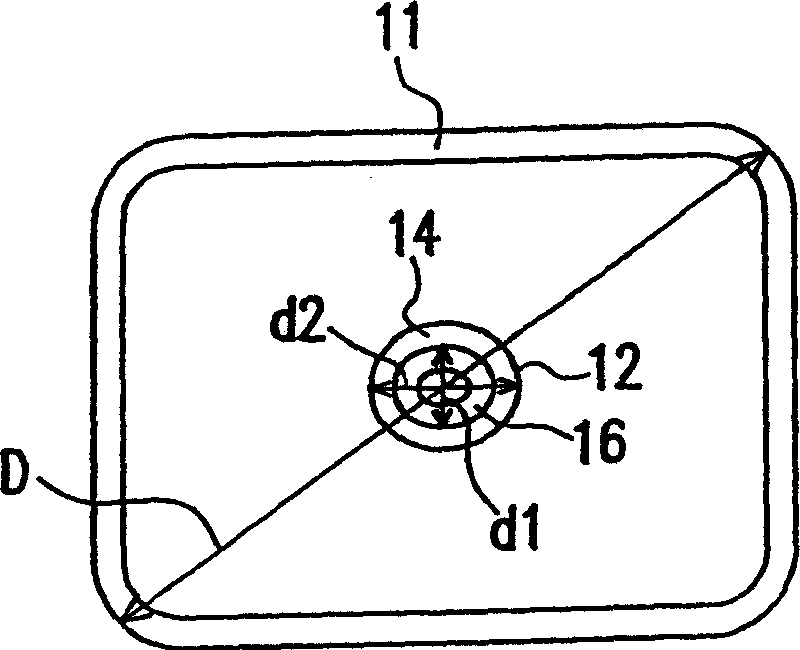

[0027]On the substantially rectangular large opening 11a of the cone 11, since the panel 18 for the projection tube is installed later, the diagonal outer diameter D of the large opening rear portion 11a of the cone 11 is the diagonal outer diameter of the panel 18 for the projection tube. The same size is 175mm.

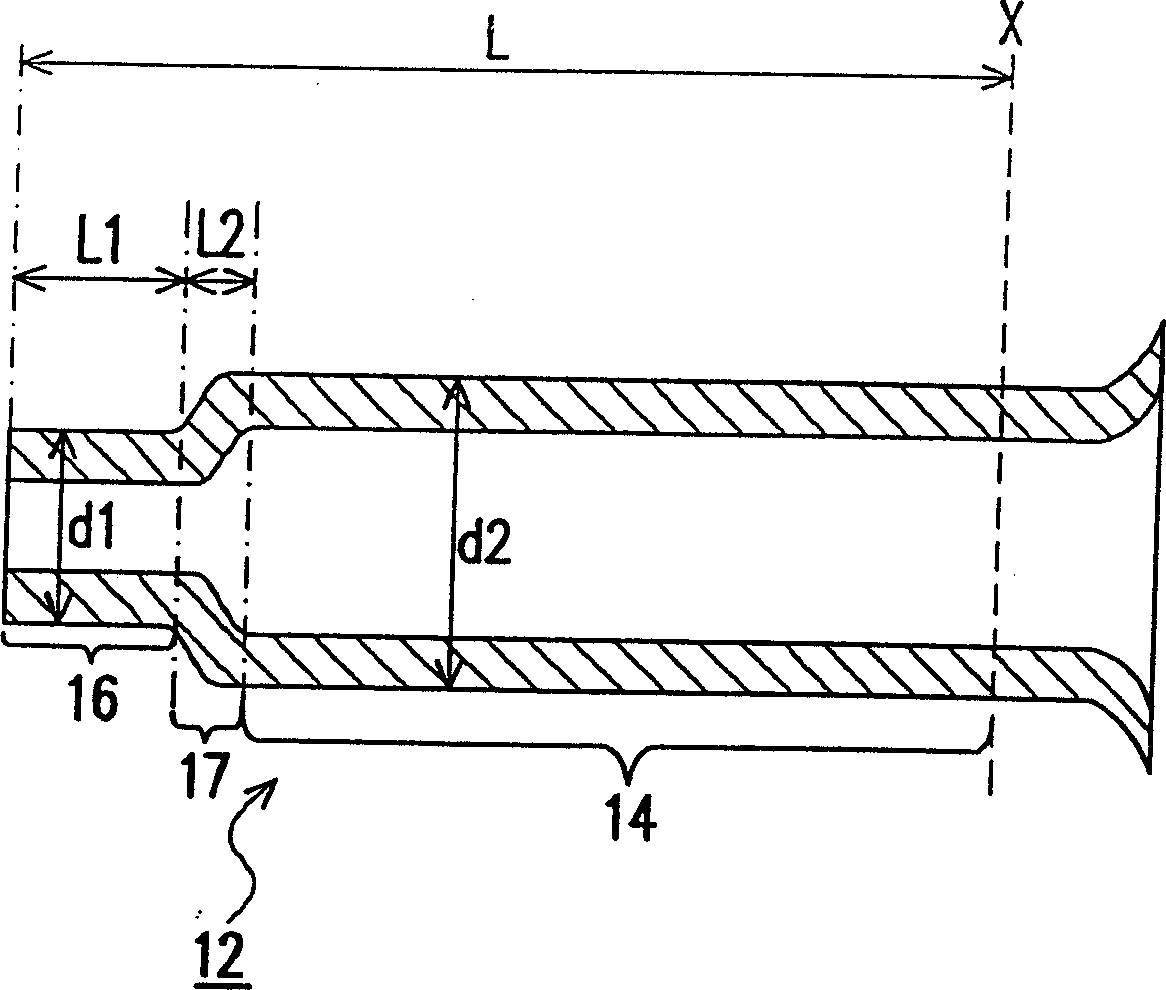

[0028] The neck tube 12 has an electron gun installation area 14 for installing an electron gun 13 inside and a deflection coil installation area 16 for installing a deflection coil 15 outside. The glass wall thickness of the neck tube 12 is 2.5mm, and the outer diameter d1 of the deflection coil installation area 16 is 29.1 mm. mm, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com