Process for producing light-emitting and/or light-receiving semiconductor body

A semiconductor and body technology, applied in the field of semiconductor body manufacturing for light emission and/or reception, to reduce the risk of detachment and improve the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

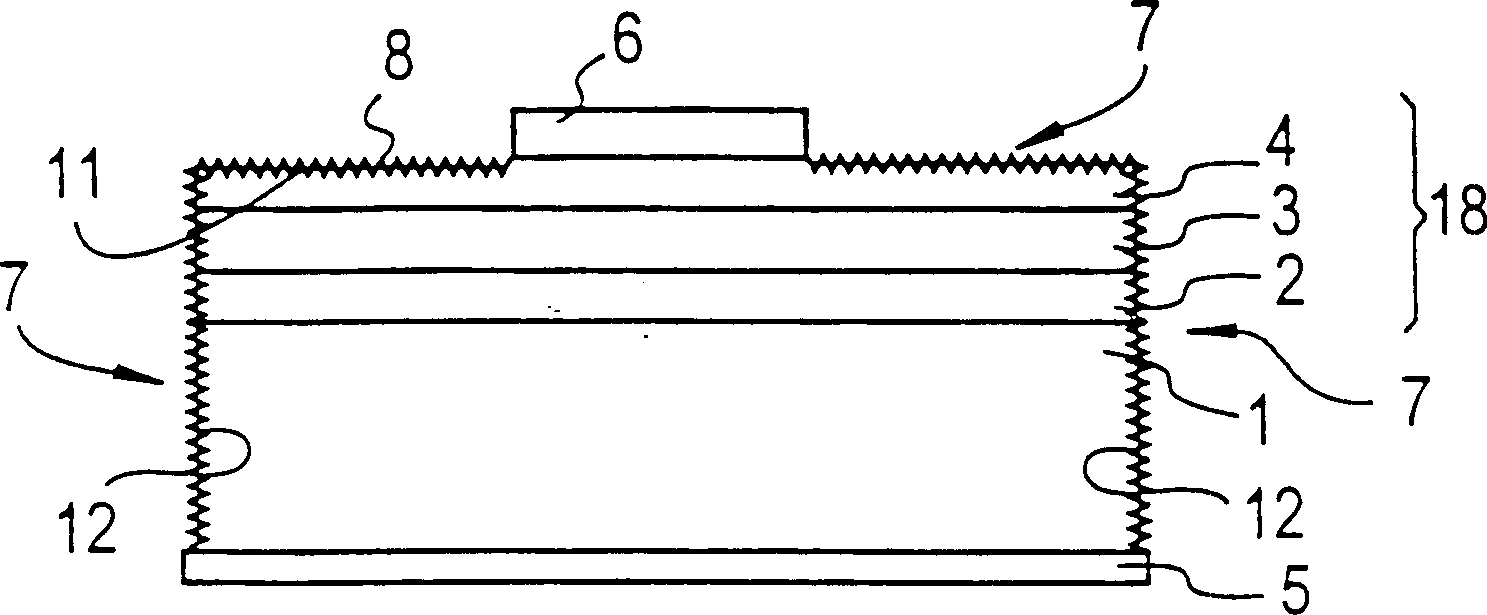

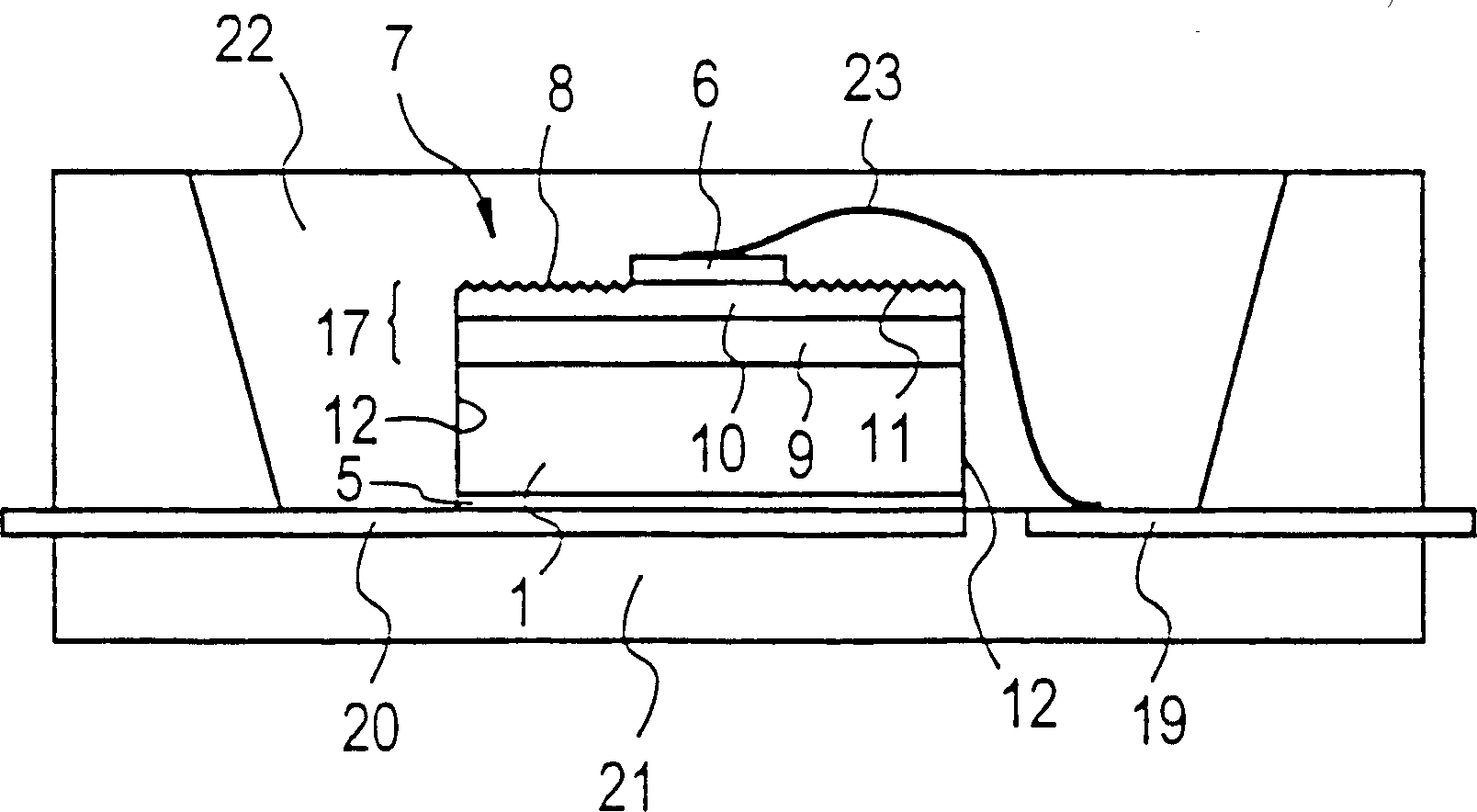

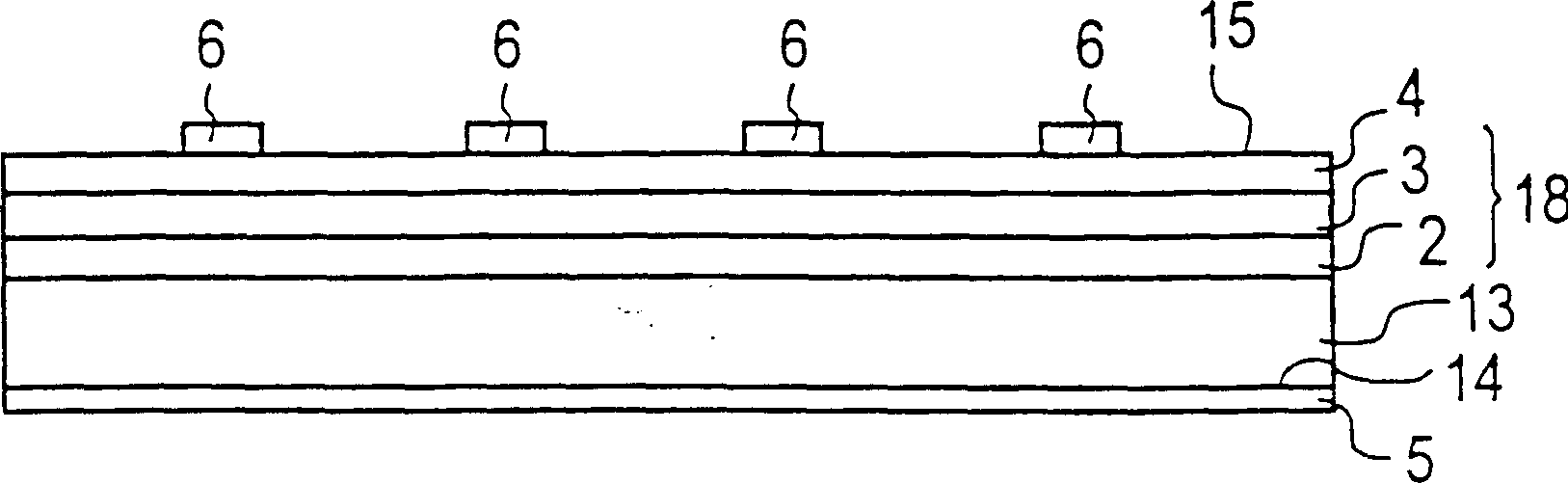

[0044] figure 1 The illustrated semiconductor body is a light-emitting semiconductor body, such as a light-emitting diode semiconductor body. In this case, a light-emitting layer sequence 18 is arranged on the GaP substrate 1 . On the GaP substrate 1 is, for example, a first GaAs x P 1-X Epitaxial layer 2, where 0≤xx P 1-X Epitaxial layer 3, where 0≤x<1. For example, Te or S can be used as n-type dopant material.

[0045] In the second GaAs x P 1-X The epitaxial layer 3 is coated with p-doped third GaAs x P 1-X The epitaxial layer 4, where 0≤xx P 1-X The epitaxial layer 2 has an increased As content, such as from x=0 until x=second GaAs x P 1-X As content of the epitaxial layer 4.

[0046] The bottom surface of the GaP substrate 1 is configured with a first contact metallization layer 5, which includes a layer sequence such as Au—Ge alloy / Ag / Au. In the third GaAs x P 1-X The top surface of the epitaxial layer 4 is configured with a second contact metallization l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com