Grinding fluid in use for superhard abrasive grinding wheel of metal binding agent electrolyzable online, and preparation method

A metal bond and superabrasive technology, applied in the field of grinding fluid, can solve the problems of short service life and poor geometric shape retention of the working surface, and achieve the effect of fast speed, strong adhesion and uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: implementation condition: M7130 type horizontal shaft rectangular platform surface grinder, each piece of metal bond CBN grinding wheel and vitrified bond CBN grinding wheel that can be electrolyzed online, the granularity of grinding wheel is 120#, the linear velocity Vs=20m / s of grinding wheel , table feed speed f = 10m / min, grinding wheel feed a p =0.0025mm, the workpiece material is HR-1 hydrogen-resistant stainless steel. The metal bond CBN grinding wheel 1 that can be electrolyzed online is made as follows:

[0033] Abrasive: 120# particle size, 100% concentration of CBN

[0034] Binder: It is made of 80% iron powder, 10% copper powder, 5% nickel powder and 5% ferric oxide powder. Wherein percentage is mass percent.

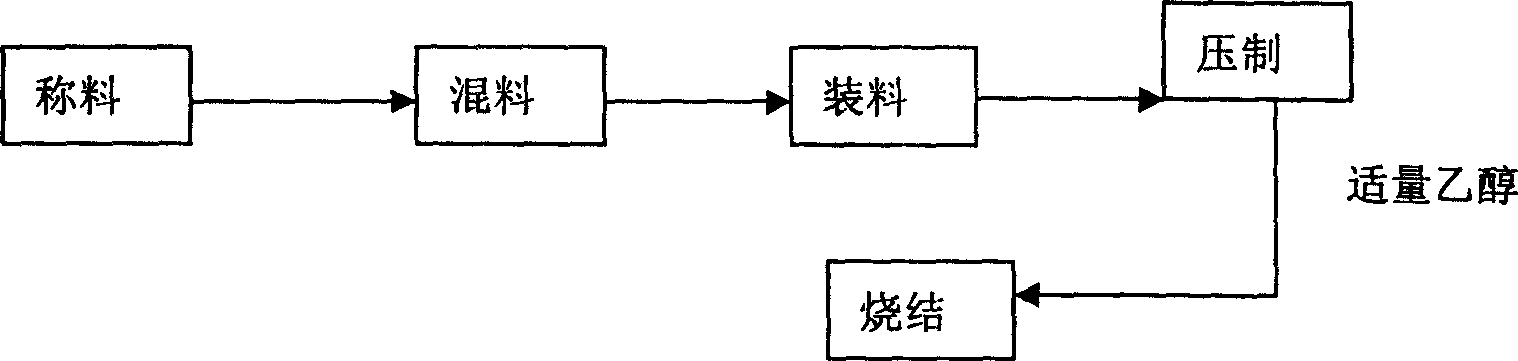

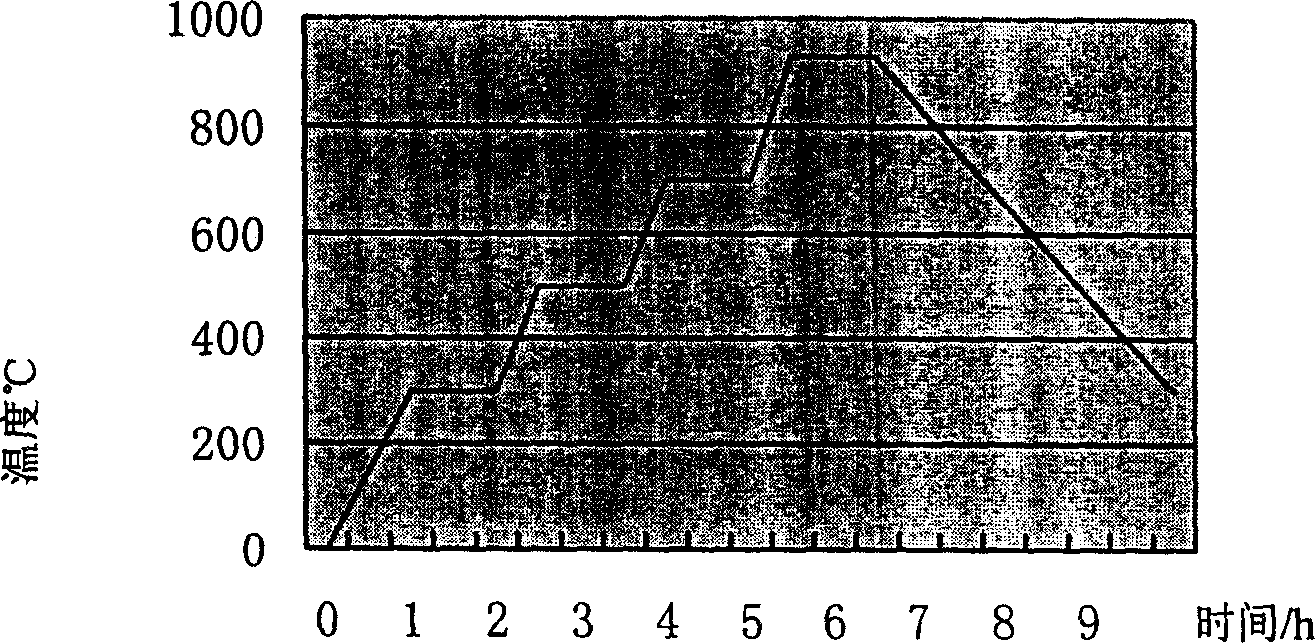

[0035] Sintering method: use the above-mentioned cold pressing sintering method to make the grinding wheel.

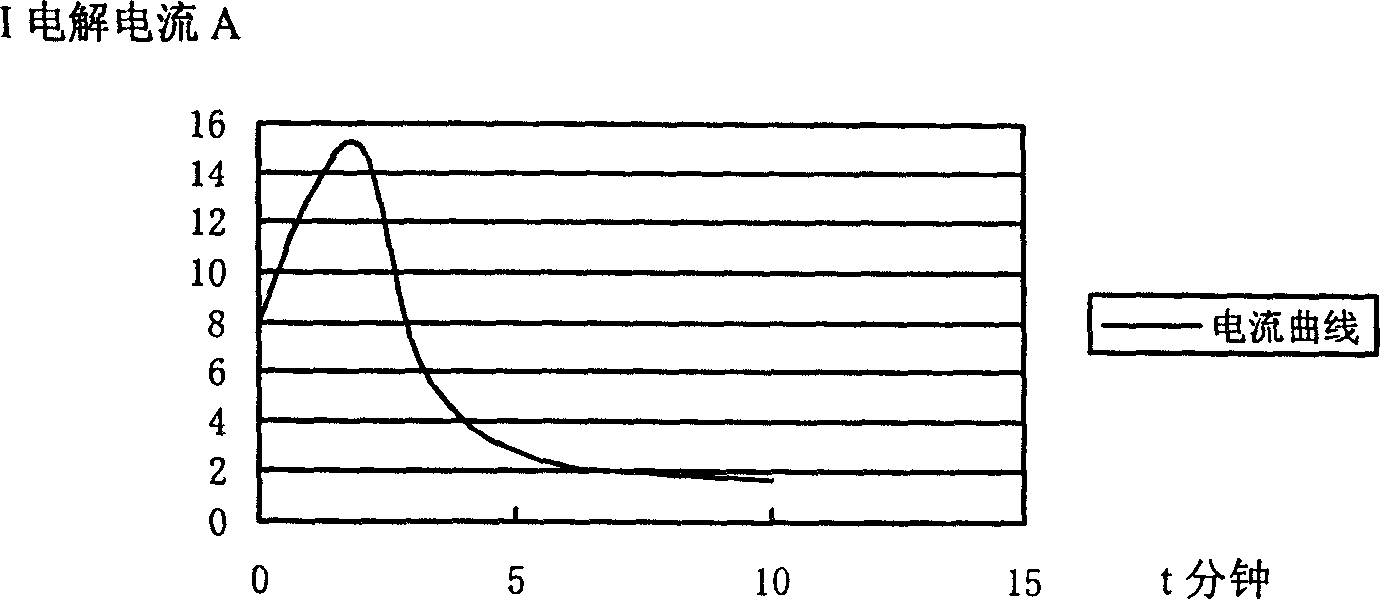

[0036] The preparation method of the grinding fluid used in conjunction with the above grinding wheel is as follows:

[0...

Embodiment 2

[0044] Embodiment 2: implementation conditions: M7130 type horizontal shaft rectangular table surface grinder, each piece of metal bond CBN emery wheel and vitrified bond CBN emery wheel that can be electrolyzed online, the granularity of emery wheel is 120#, and the grinding consumption of use is the line of emery wheel Speed Vs=20m / s, table feed speed f=10m / min, grinding wheel feed a p =0.0025mm, the workpiece material is steel bonded carbide.

[0045]The manufacturing method of metal-based diamond and CBN mixed abrasive grinding wheel 2 is as follows:

[0046] Abrasive: 120# particle size, 100% concentration of diamond and CBN mixed abrasive.

[0047] Binder: It is made of 70% iron powder, 10% copper powder, 10% silver powder, 2% tin powder, 3% zinc powder and 5% ferric oxide powder. Wherein percentage is mass percent.

[0048] Sintering method: use the above-mentioned cold pressing sintering method to make the grinding wheel.

[0049] The preparation method of the gr...

Embodiment 3

[0057] Embodiment 3: implementation conditions: M7130 type horizontal shaft rectangular table surface grinder, each piece of metal bond CBN emery wheel and vitrified bond CBN emery wheel that can be electrolyzed online, the granularity of emery wheel is 120#, and the grinding consumption that uses is the line of emery wheel Speed Vs=20m / s, table feed speed f=10m / min, grinding wheel feed a p =0.0025mm, the workpiece material is cemented carbide. The manufacture method of metal-based diamond abrasive grinding wheel 3 is as follows:

[0058] Abrasive: 120# particle size, 100% concentration of diamond abrasive.

[0059] Binder: It is made of 60% iron powder, 15% copper powder, 15% tin powder, 5% zinc powder and 5% graphite powder. Wherein percentage is mass percent.

[0060] Sintering method: use the above-mentioned cold pressing sintering method to make the grinding wheel.

[0061] The preparation method of the grinding fluid used in conjunction with the above grinding whee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap