Soft tissue paper having surface deposited softening agent

A technology of tissue paper and softener, which is applied in the direction of papermaking, paper, patterned paper, etc., and can solve the problems of loss of tensile strength and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

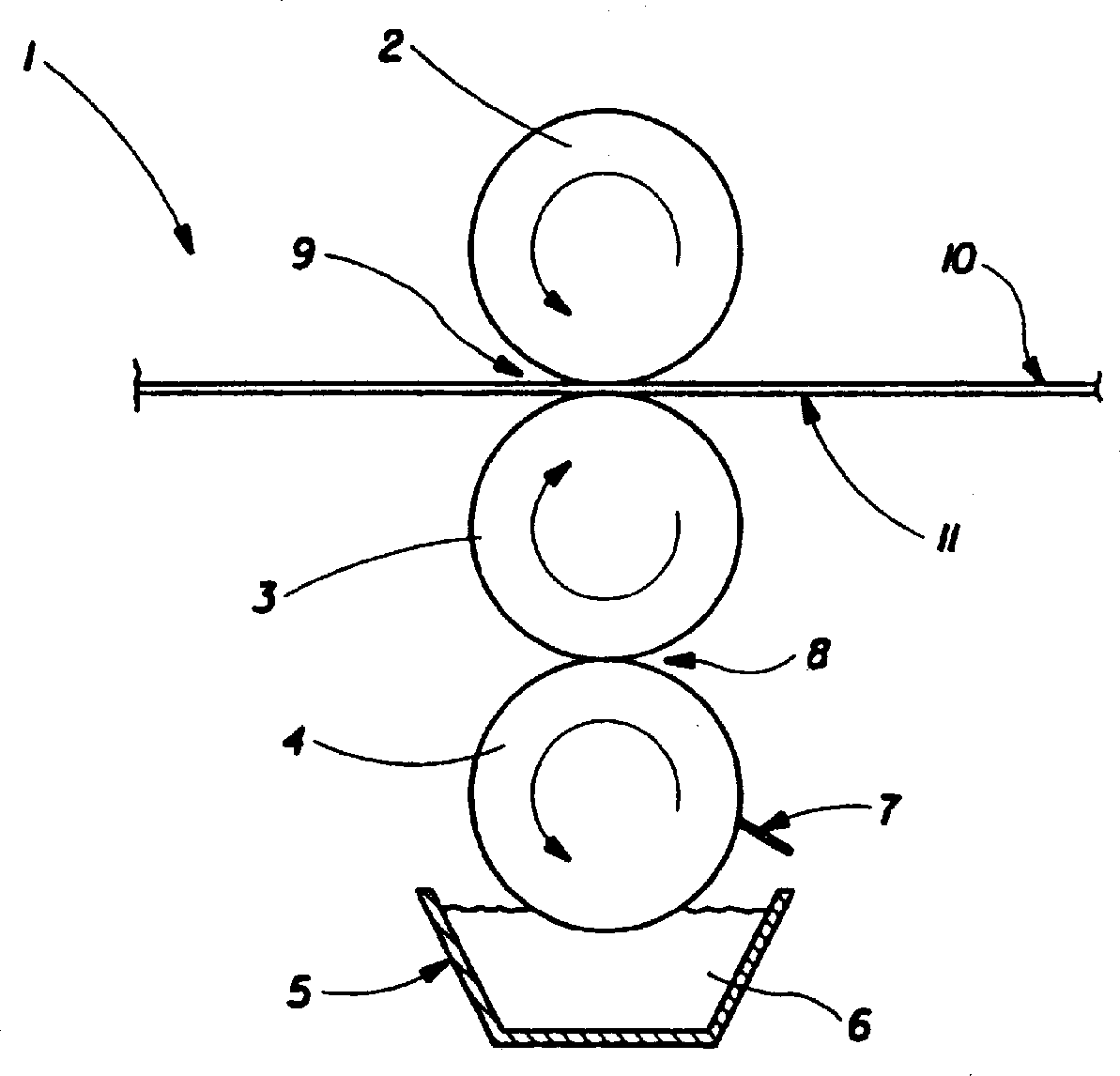

[0233] This example illustrates the use of an offset rotogravure press to produce a two-ply bath tissue with a uniform, discrete deposit of directly immobilized chemical softener.

[0234] The reagents to prepare a soft solution are:

[0235] 1. Tallow diester chloride quaternary ammonium salt (ADOGEN SDMC) available from WITCO Chemical Company of Greenwich, CT.

[0236] 2. Polyethylene glycol 400 available from J.T. Baker Company of Phillipsburg, NJ.

[0237] 3. Isostearic acid (Century 1105, available from Union Camp, Wayne, NJ).

[0238] Melt and stir 75% tallow diester chloride quaternary ammonium salt, 20% polyethylene glycol 400, and 5% isostearic acid in a 140°F thermostatic vessel to make a soft solution, which is then loaded into a gravure tank , so that the softening solution fills the recessed area of the rotogravure cylinder.

[0239] The gravure cylinder structure included a central void for circulation of heated fluid to maintain the roll surface temperature...

Embodiment 2

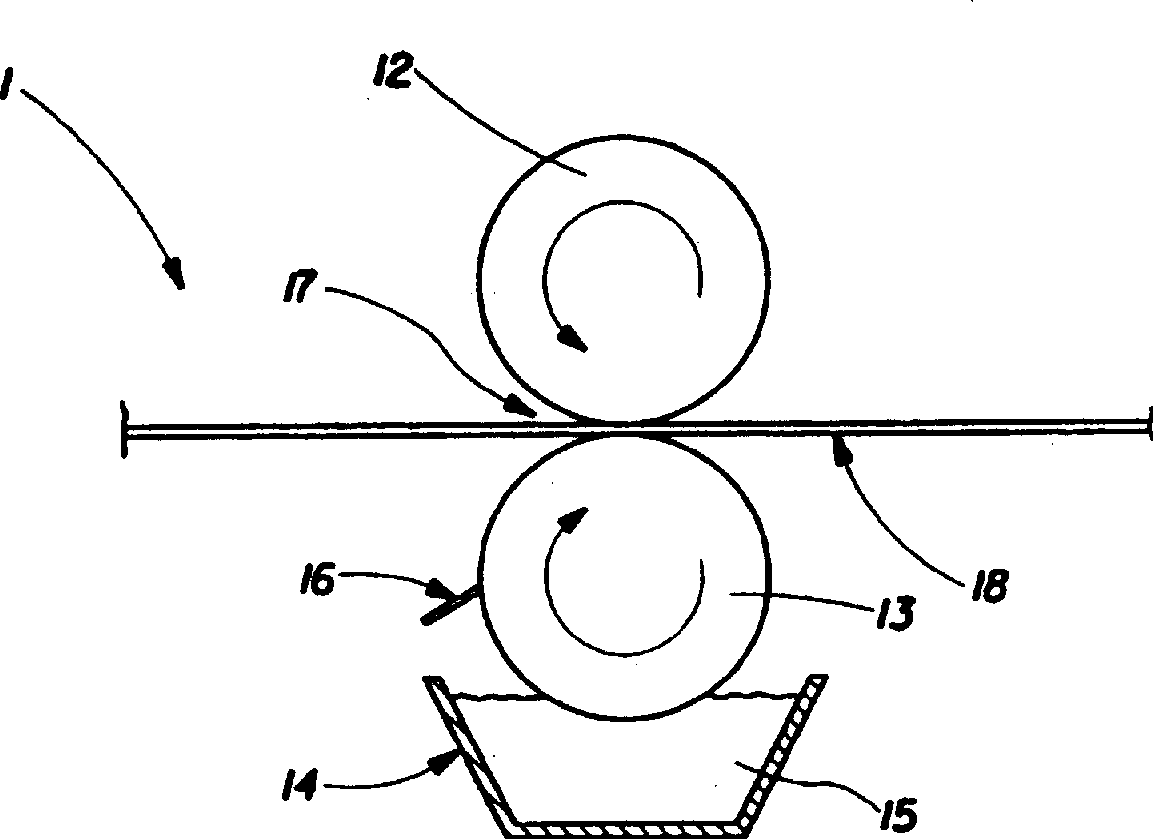

[0247] This example illustrates the use of an offset rotogravure press to produce a two-ply bath tissue with a uniform, discrete deposit of directly immobilized chemical softener.

[0248] The reagents to prepare a soft solution are:

[0249] 1. Tallow diester chloride quaternary ammonium salt (ADOGEN SDMC) available from WITCO Chemical Company of Greenwich, CT.

[0250] 2. Polyethylene glycol 400 available from J.T. Baker Company of Phillipsburg, NJ.

[0251] 3. Isostearic acid (Century 1105, available from Union Camp, Wayne, NJ).

[0252] 4. Amodimethicone (SF1921, available from GE Silicones of Waterford, NY).

[0253] Melt and stir 33.8% tallow diester chloride quaternary ammonium salt, 9% polyethylene glycol 400, 2.3% isostearic acid, and 55% SF1921 in a 140°F thermostatic vessel to make a soft solution, then fill On the gravure tank, the soft solution fills the recessed area of the rotogravure cylinder.

[0254] The gravure cylinder structure included a central voi...

Embodiment 3

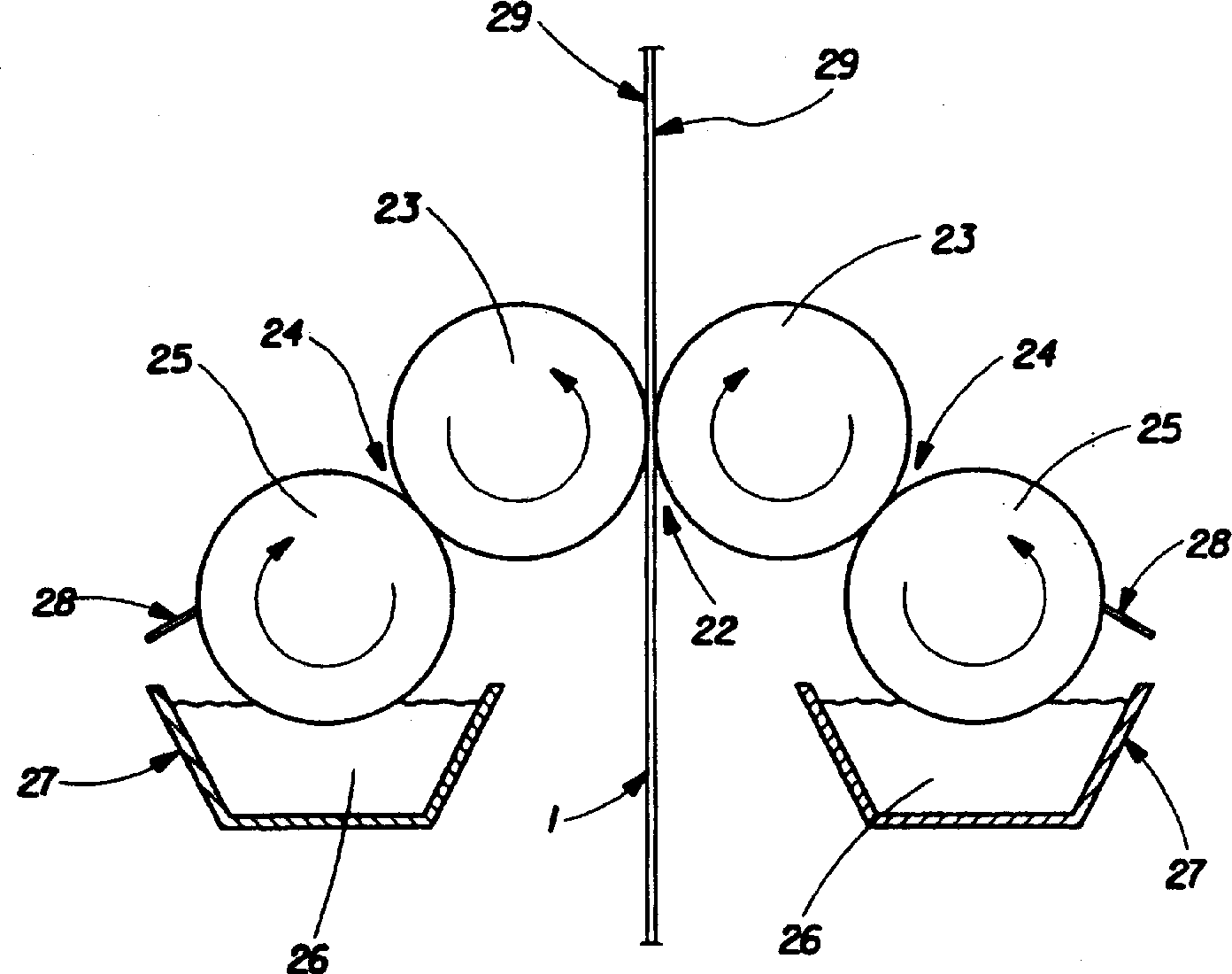

[0262] This example illustrates the use of an offset rotogravure press to produce a two-ply bath tissue with a uniform, discrete deposit of directly immobilized chemical softener.

[0263] The reagents to prepare a soft solution are:

[0264] 1. Tallow diester chloride quaternary ammonium salt (ADOGEN SDMC) available from WITCO Chemical Company of Greenwich, CT.

[0265] 2. Polyethylene glycol 400 available from J.T. Baker Company of Phillipsburg, NJ.

[0266] 3. Isostearic acid (Century 1105, available from Union Camp, Wayne, NJ).

[0267] A soft solution was prepared by melting and stirring 76% tallow diester chloride quat, 20% polyethylene glycol 400, and 4% isostearic acid in a 140°F thermostatic vessel, then loaded onto the gravure tank , so that the softening solution fills the recessed area of the rotogravure cylinder.

[0268] The gravure cylinder structure included a central void for circulation of heated fluid to maintain the roll surface temperature at 140°F. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com