Buttonhole serging machine and method for forming stitch thereof

A sewing machine and buttonhole technology, which is applied to sewing machine components, program-controlled sewing machines, sewing equipment, etc., can solve the problems of product quality degradation, fiber shedding and loosening, etc., and achieve the effect of improving quality and eliminating cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described below with reference to the drawings.

[0045] Further, details of the structure of the sewing machine and a method of forming buttonholes using the structure of the sewing machine are described in detail in Japanese Patent Application Laid-Open No. 11-9859 as an invention filed by the applicant earlier.

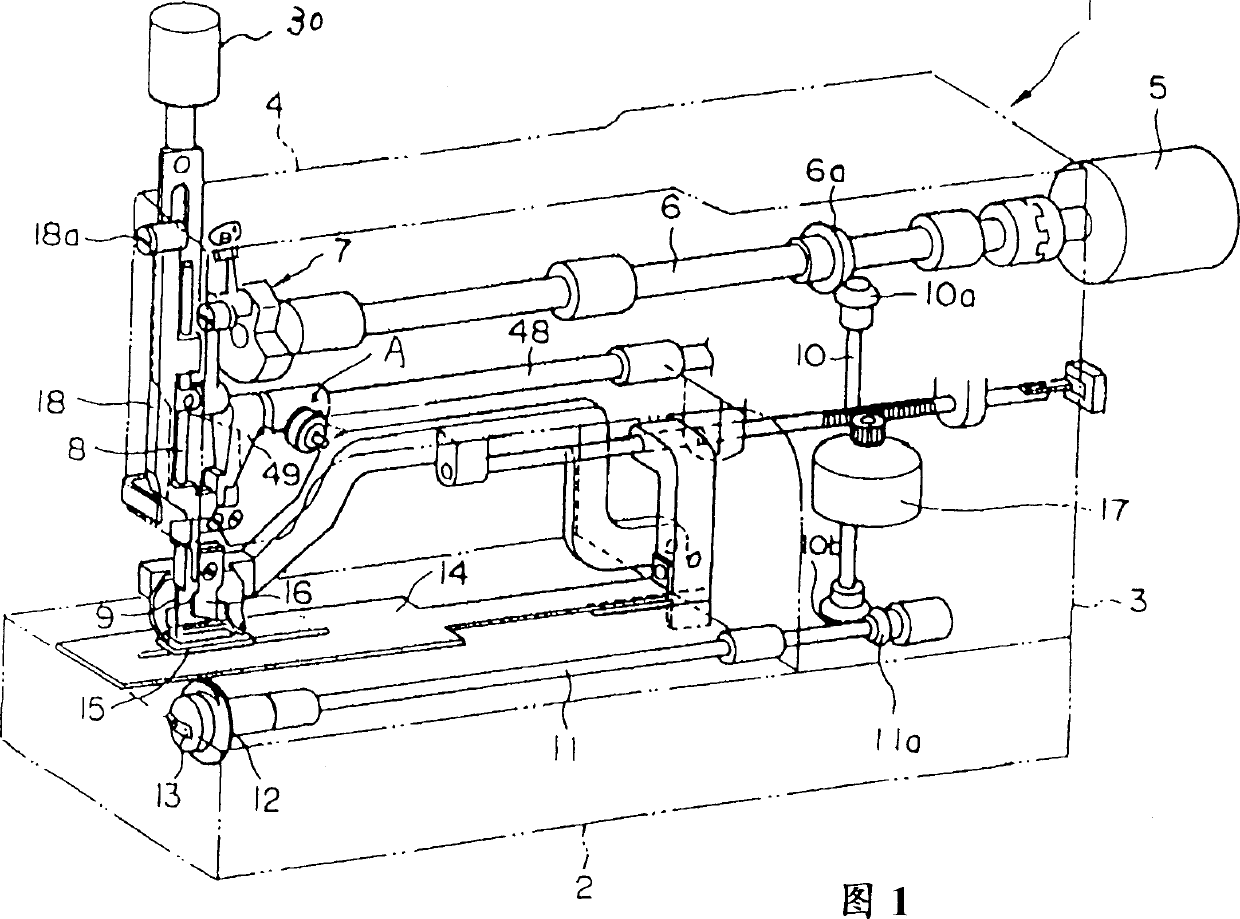

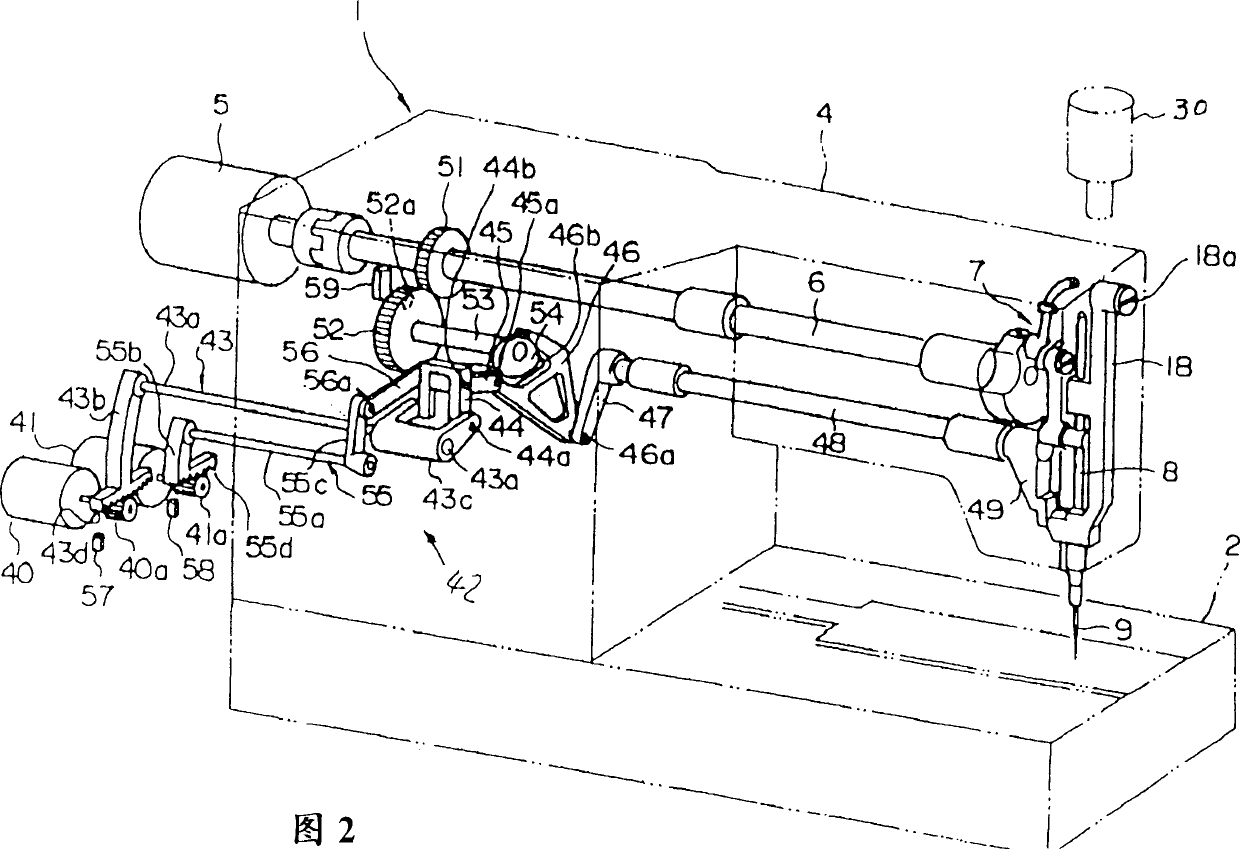

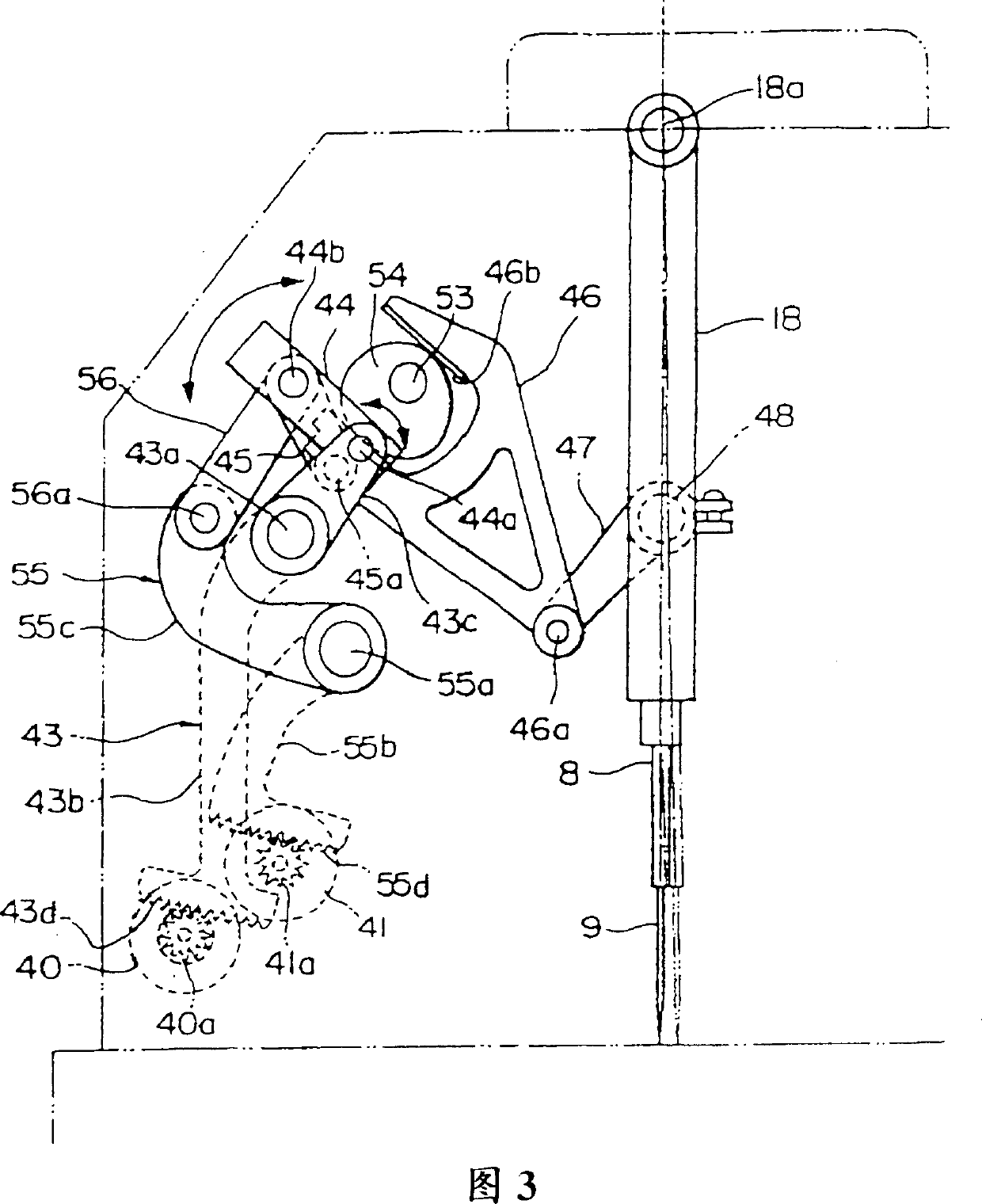

[0046] In FIGS. 1 to 3 , a sewing machine 1 consists of a base 2 with a flat base surface on the upper surface, a vertical body portion 3 erected on one end side of the base 2 , and a vertical body portion 3 from the vertical body portion 3 . It is formed along the arm portion 4 that extends substantially parallel to the base 2, and is substantially U-shaped when viewed from the side.

[0047] In the above-mentioned sewing machine 1, the main motor 5 is provided at one end of the vertical body part 3, and the needle bar 8 is connected to the upper shaft 6 driven to rotate by the main motor 5 via the crank mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com