Coated optical fibers

An optical fiber and coating technology, applied in the direction of light guide, cladding optical fiber, glass optical fiber, etc., can solve problems such as high stress and abnormal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

comparative test A

[0301] The coating was prepared using 50% by weight of polyether urethane acrylate (theoretical molecular weight about 9000), about 20% by weight of 8 ethoxylated nonylphenol acrylates, 20% by weight of lauryl acrylate, 6% N-vinylcaprolactam, 1.5% by weight of Lucirine TPO, 0.8% by weight of Irganox 1035, 0.1% by weight of diethanolamine and 0.3% by weight of Seesorb 102.

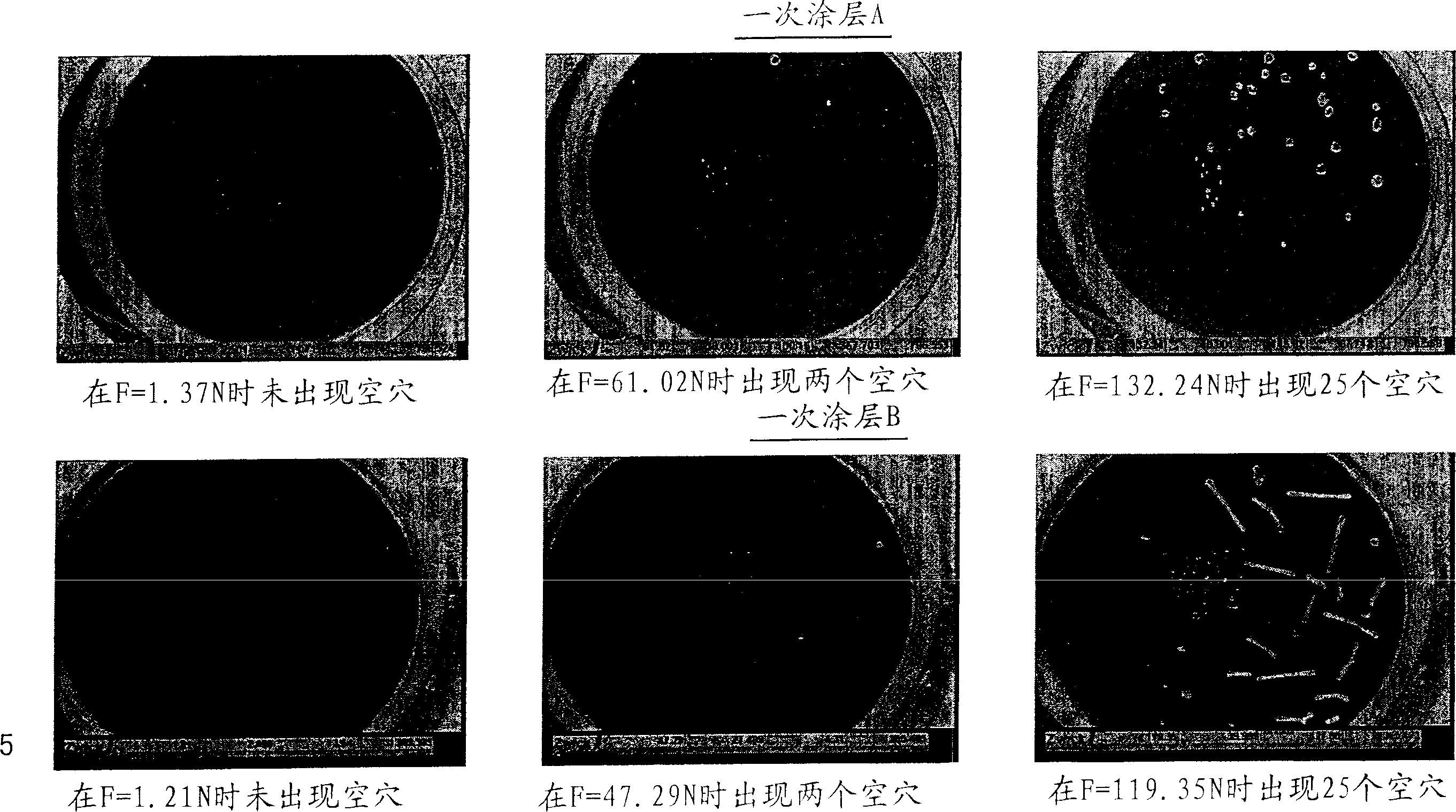

[0302] The measurement results are as follows: the equilibrium modulus is 0.4MPa, E' 23 It is 0.5MPa, the strain hardening is very small, Go=26J / m 2 . Use 1J / cm 2 The amount of radiation for curing. In the relative Mooney graph of Figure 4, this coating is represented by the graph of Comparative Example A. The hole intensity σ where the tenth hole appears 10 It is 0.96MPa (see Figure 3).

[0303] Compare Test B and Example 1

[0304] A general-purpose coating with an equilibrium modulus of 1.0 MPa is used. In comparative test B, the sample was used with 1J / cm 2 The amount of radiation for curing. ...

comparative test C

[0315] Prepare the coating with 60% by weight of polyether urethane acrylate (theoretical molecular weight is about 4000), 18.6% by weight of 4 ethoxylated nonylphenol acrylates, 4% by weight of 1-2-hydroxypropyl Phenoxyacrylate, 7% by weight lauryl acrylate, 7.8% by weight N-vinylcaprolactam, 1.2% by weight Lucirine TPO, 0.3% by weight Irganox 1035 and 1% by weight diethanolamine.

[0316] The test results are as follows: the equilibrium modulus is 1.2 MPa. Calculated volumetric thermal expansion coefficient α 23 is 7.15×10 -4 K -1 .

[0317] The comparison between the primary coating of Example 3 and the coating of Comparative Test C shows that the coating of Example 3 (its α 23 The actual stress level in the claims) is reduced. In the primary coating, the gain in stress reduction depends on the volumetric thermal expansion coefficient of the secondary coating. In general, for α 23 3.0×10 -4 K -1 The stress on the primary coating of Example 3 is about 20% lower than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com