Method and tool for producing a press joint connection

A connection method and a technology of connectors, which are applied in connection, manufacturing tools, metal processing equipment, etc., can solve problems such as elastic limitations of connection points, and achieve the effect of high working capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

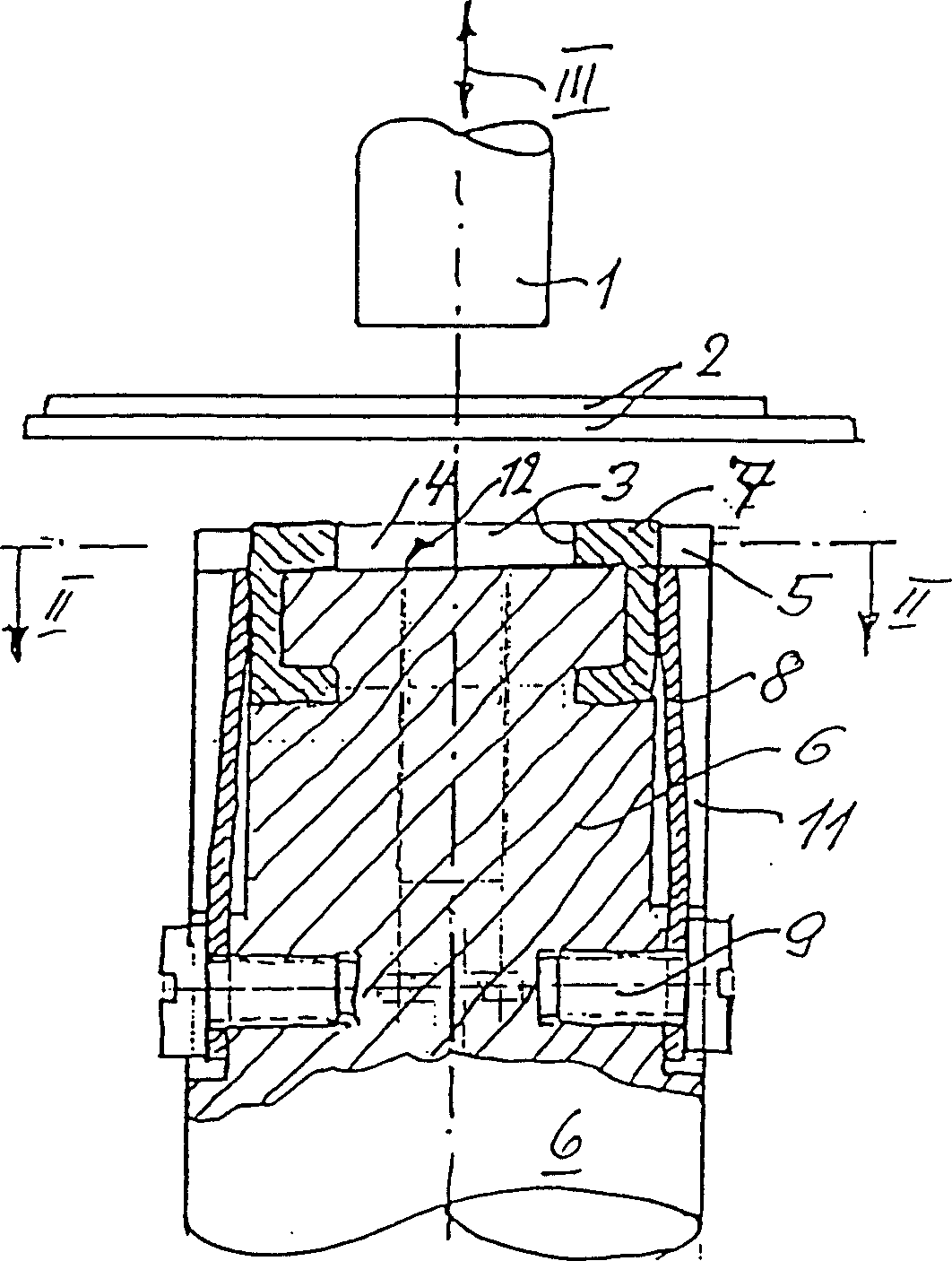

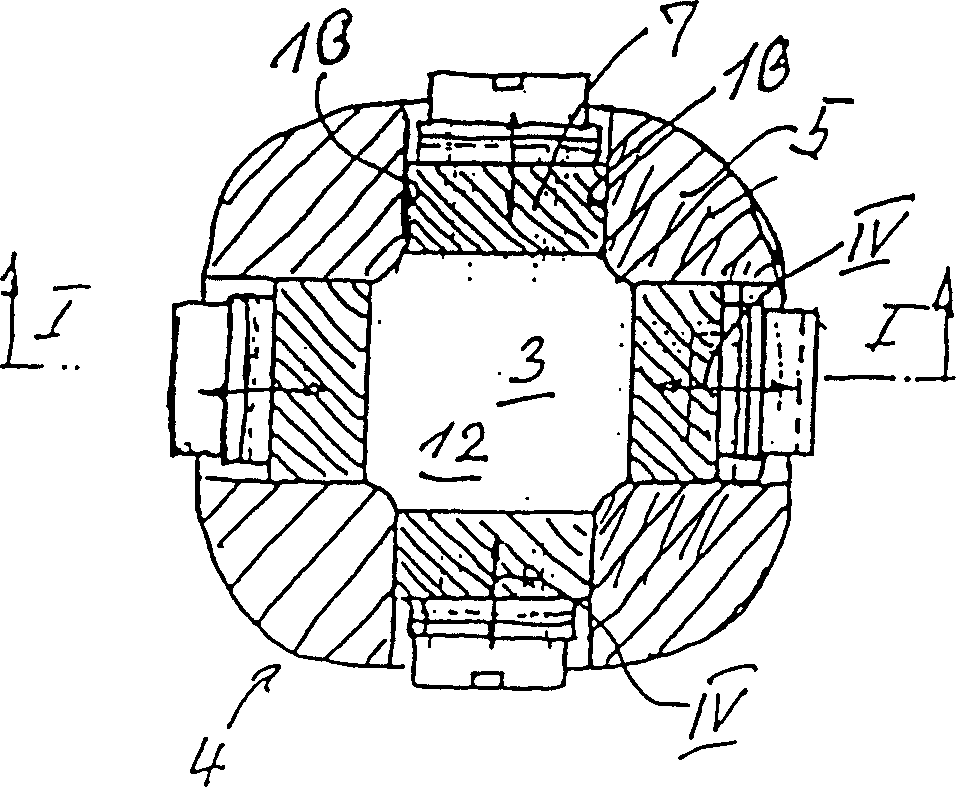

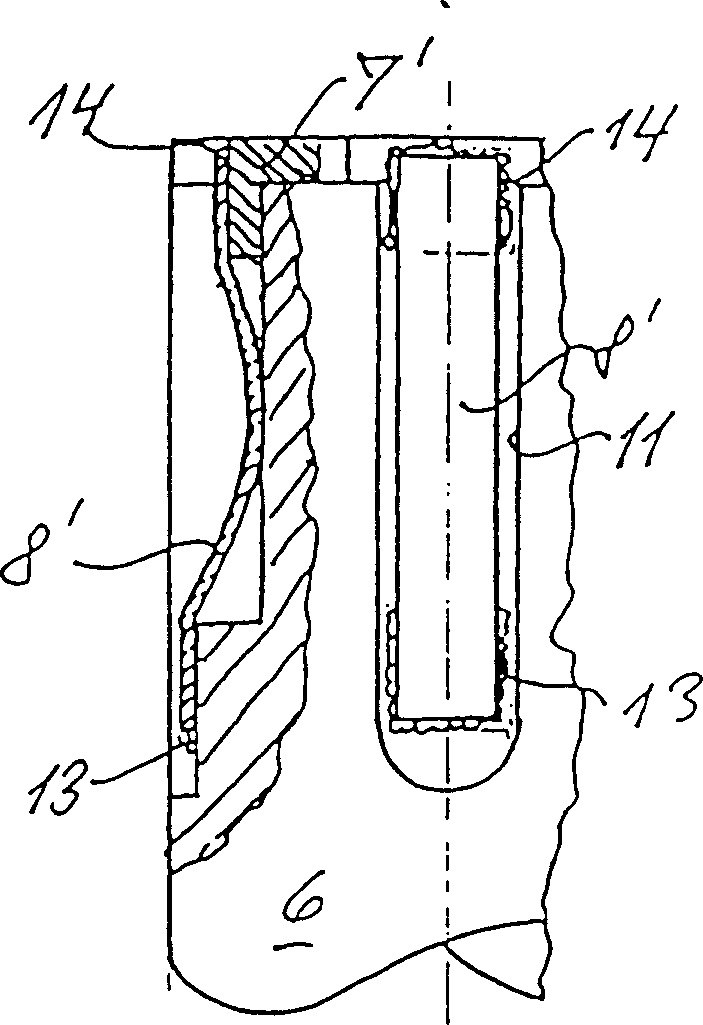

[0026] figure 1 Shown according to the tool of the present invention in the explosion stroke diagram, that is, the punch 1 corresponding to the arrow III can control its working stroke, and can press two mutually overlapping plates 2 into the die 4 in a hole 3. The die is formed by a stationary wall section 5 of the forging die 6 and by a radially outwardly movable bracket 7 which is moved by means of a leaf spring 8 into the starting position shown in the figure. The leaf spring 8 is fixed on the forging die 6 with screws 9 and is arranged in the longitudinal groove 11 of the forging die 6 . Bore 3 is bounded downwards by a base plate 12 formed by die 6 .

[0027] like figure 2 As shown, the bow 7 between the fixed wall plates 5 of the forging die 6 can be moved axially. The guide wall 13 on the fixed wall section 5 thus serves as a die. During movement, the bracket 7 slides onto the bottom 12 of the blind hole 3 . During the displacement, the bracket 7 moves correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com