Reactor with anaerobic suspension bed

A reactor and suspended bed technology, applied in the field of anaerobic bioreactors, can solve the problems of slow start-up, high operating costs, and easy acidification of anaerobic reactors, so as to improve impact resistance and operational stability, and shorten the start-up period , the effect of high operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Various embodiments of the present invention and their working process will be further described below in conjunction with the accompanying drawings.

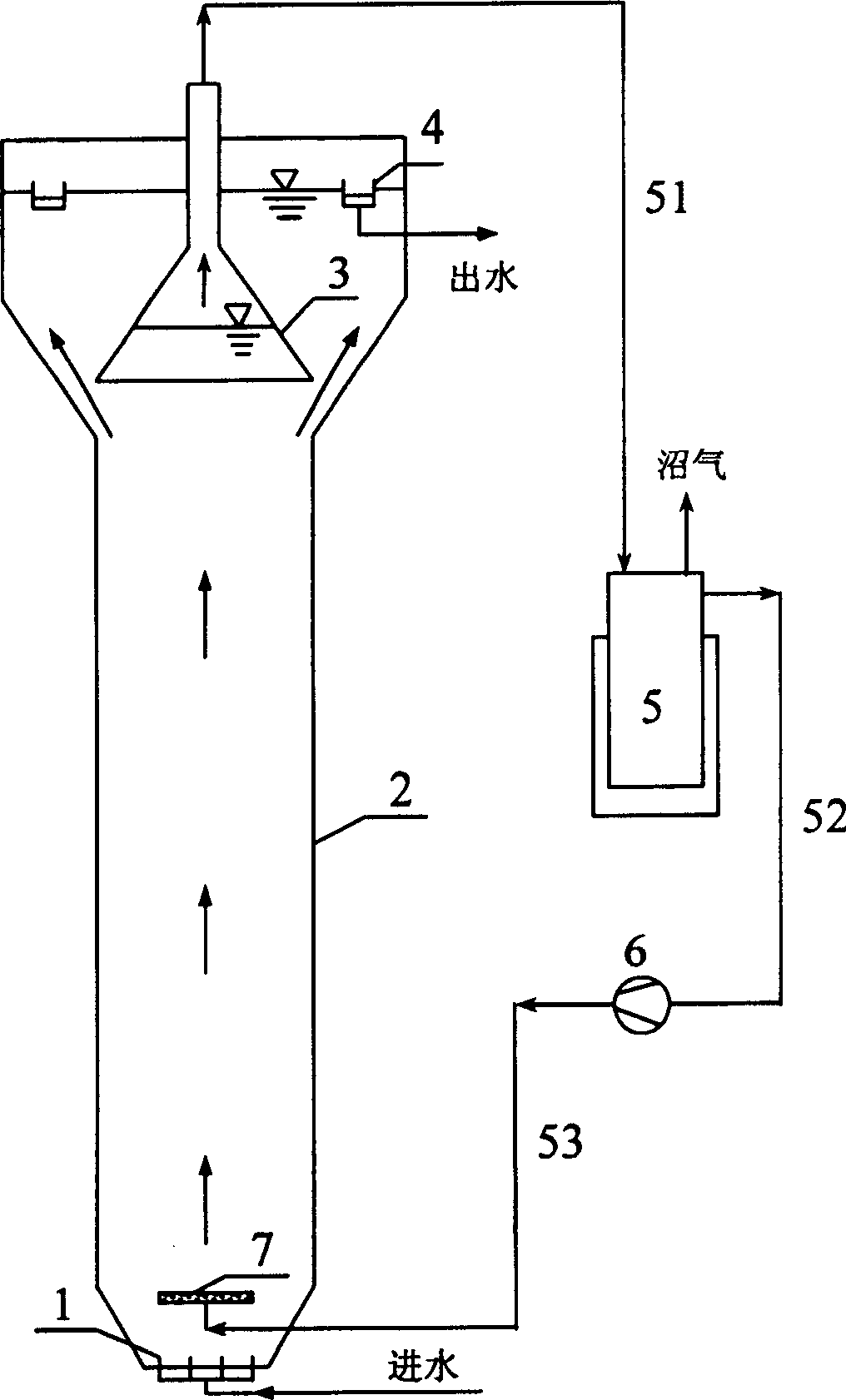

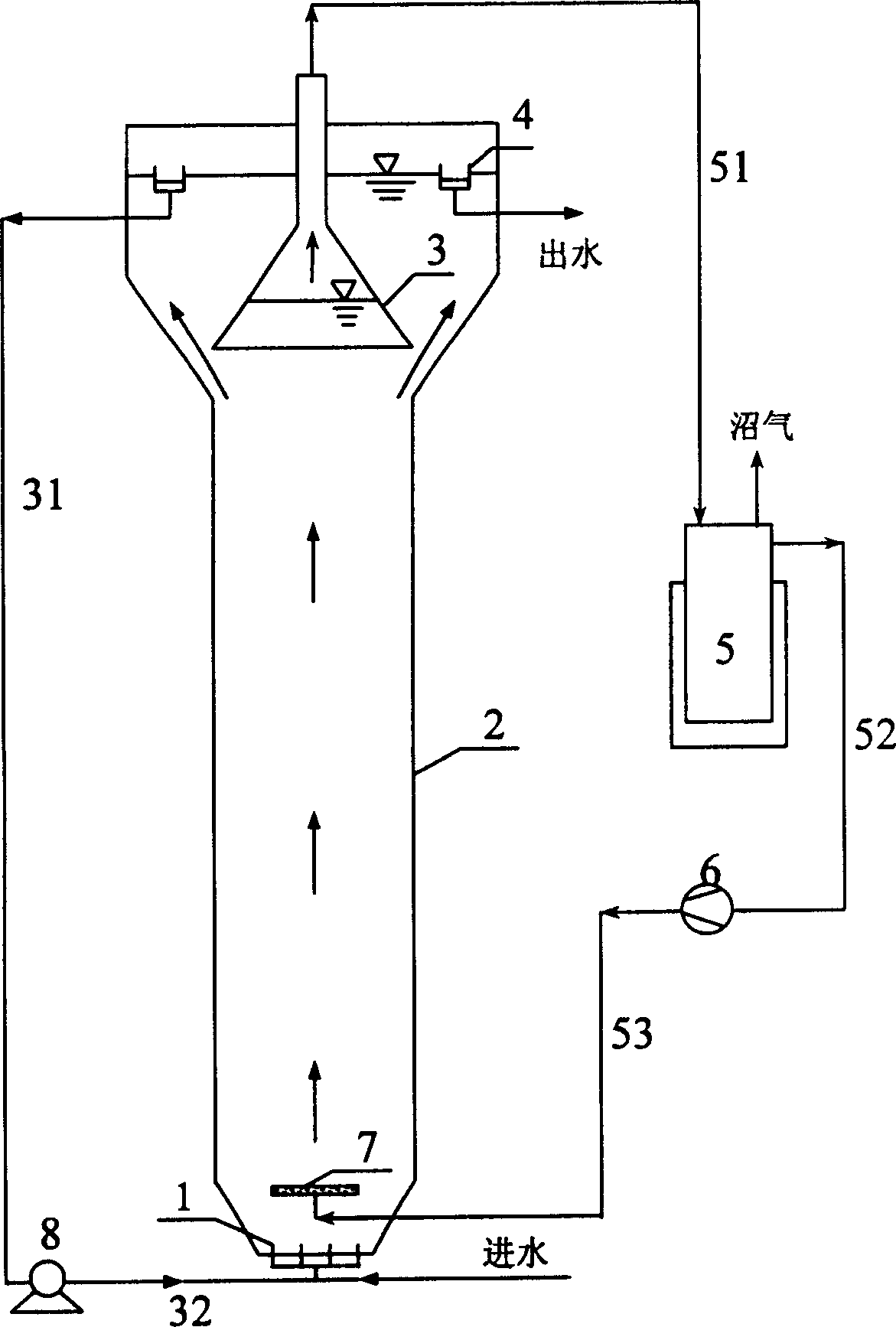

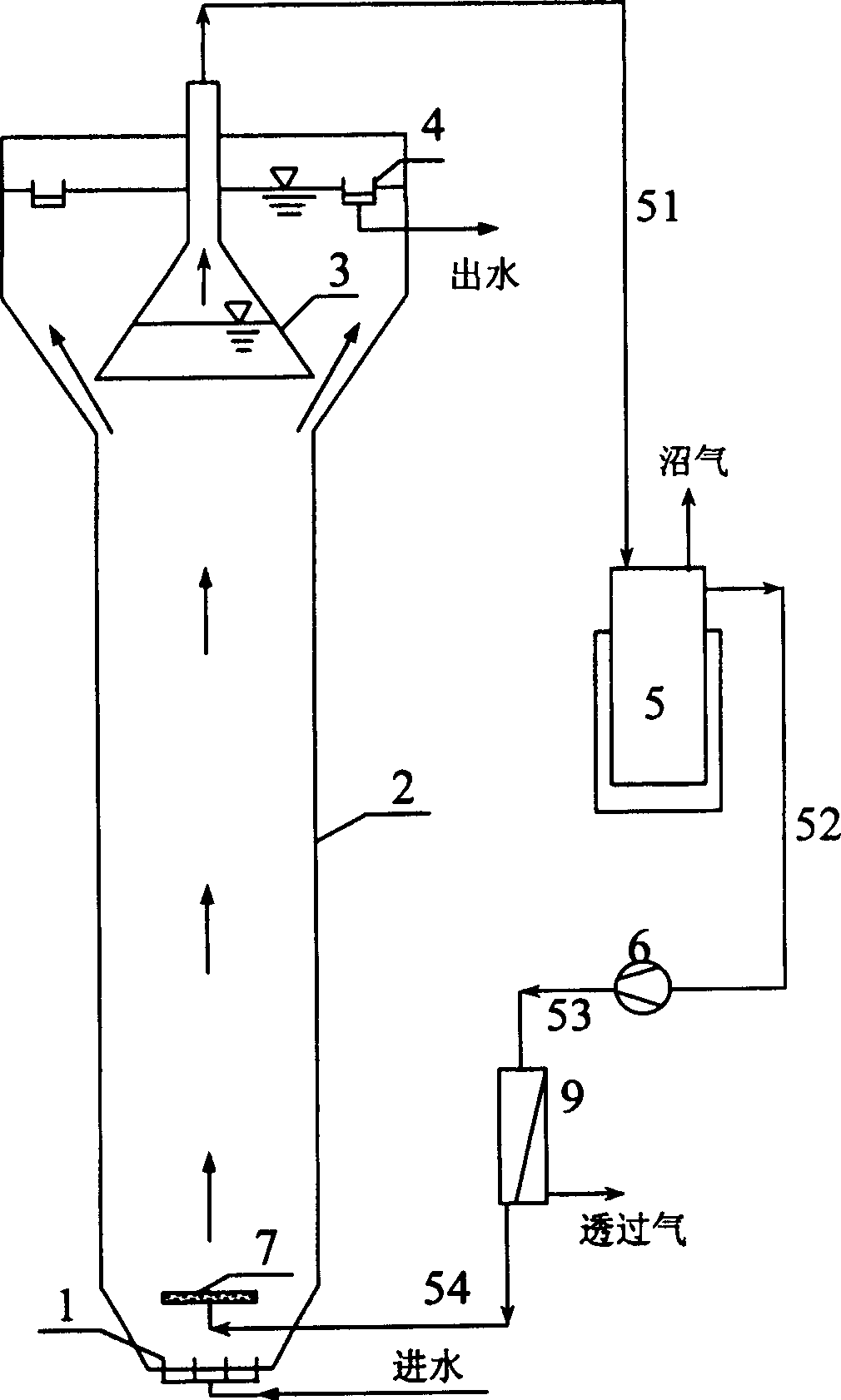

[0015] Such as figure 1 As shown, the reactor described in the first embodiment of the present invention includes a biological reaction unit and a biogas circulation unit, wherein the biological reaction unit includes a water distributor 1, a biological reaction tower 2, a three-phase separator 3 and an outlet weir 4, and the biogas The circulation unit includes a biogas buffer cabinet 5 , an air pump 6 and an air distributor 7 .

[0016] The water distributor 1 and the air distributor 7 are all arranged at the bottom of the biological reaction tower 2, the air distributor 7 is arranged above the water distributor 1, the three-phase separator 3 is arranged on the top of the biological reaction tower 2, and the water outlet weir 4 is arranged on the top of biological reaction tower 2. The three-phase separator 3 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com