Photomultiplier

A photomultiplier tube and photoelectric technology, which is applied in the direction of dynode, electron multiplier details, electrode devices with multiple dynodes, etc., can solve the problems of dynode sloshing, easy loosening, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

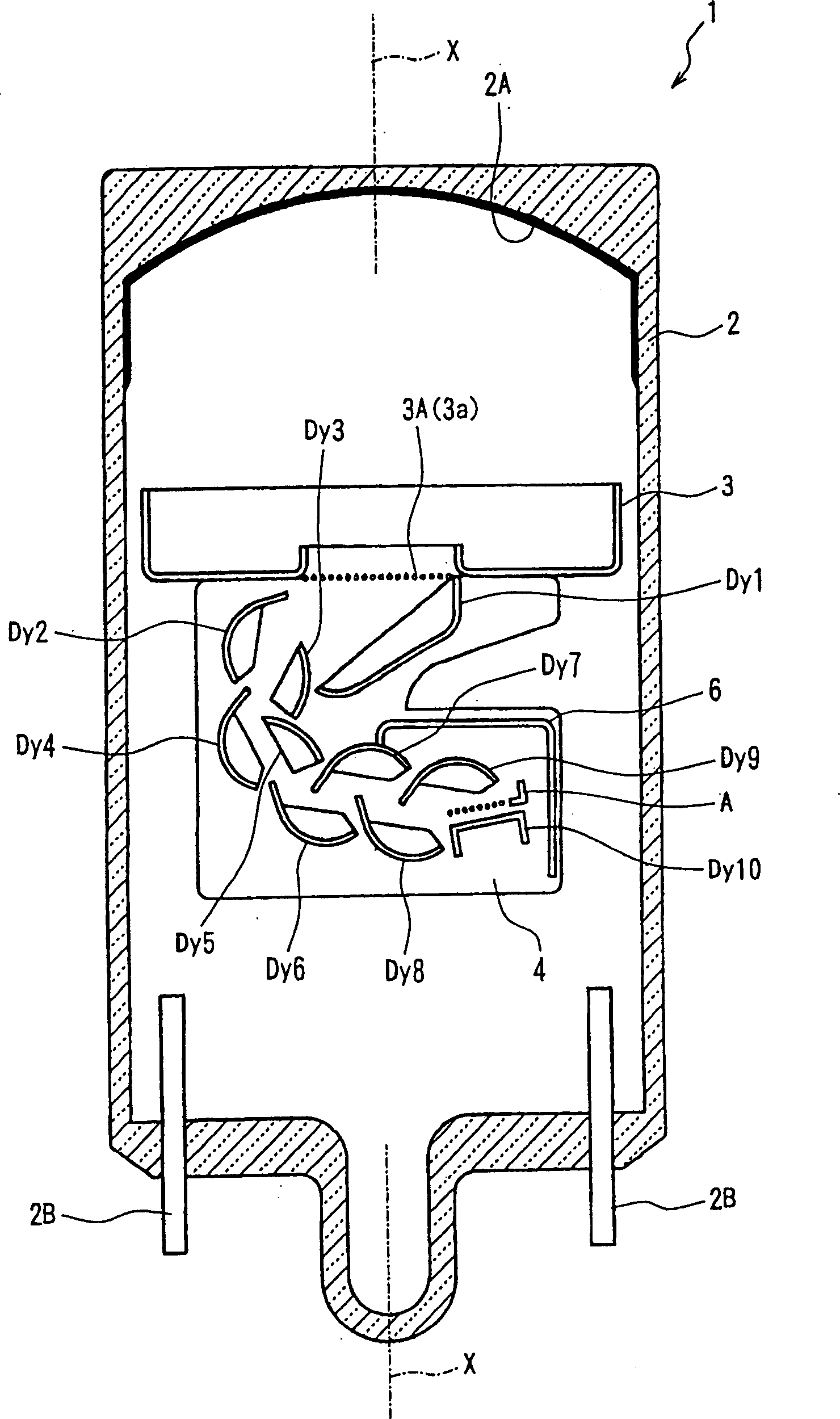

[0026] according to Figure 1-Figure 6 A photomultiplier tube according to an embodiment of the present invention will be described. The photomultiplier tube 1 of this embodiment includes a single tubular vacuum container 2 having a tube axis X. As shown in FIG. figure 1 It is a cross-sectional view showing a state where the photomultiplier tube 1 is cut along the tube axis X. FIG. The tubular vacuum vessel 2 is made of a material such as Kovar (cobalt) glass, for example.

[0027] Both ends of the tubular vacuum container 2 in the direction of the tube axis X are sealed, and one end is planar, and a photoelectric surface 2A that emits electrons upon receiving light is formed on the inner surface. The photoelectric surface 2A is formed, for example, by reacting alkali metal vapor on antimony deposited in advance on the inner surface of one end of the tubular vacuum container 2 . In addition, a plurality of conductive pins 2B are provided at the other end of the tubular vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com