Two arm shoulder joint mechanism of two arm robot and two leg hip joint mechanism of two leg walking robot

A shoulder joint and hip joint technology is applied in the field of the double-arm shoulder joint mechanism of the double-arm robot and the double-leg hip joint mechanism of the biped walking robot, and can solve the problems of increasing the degree of freedom and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

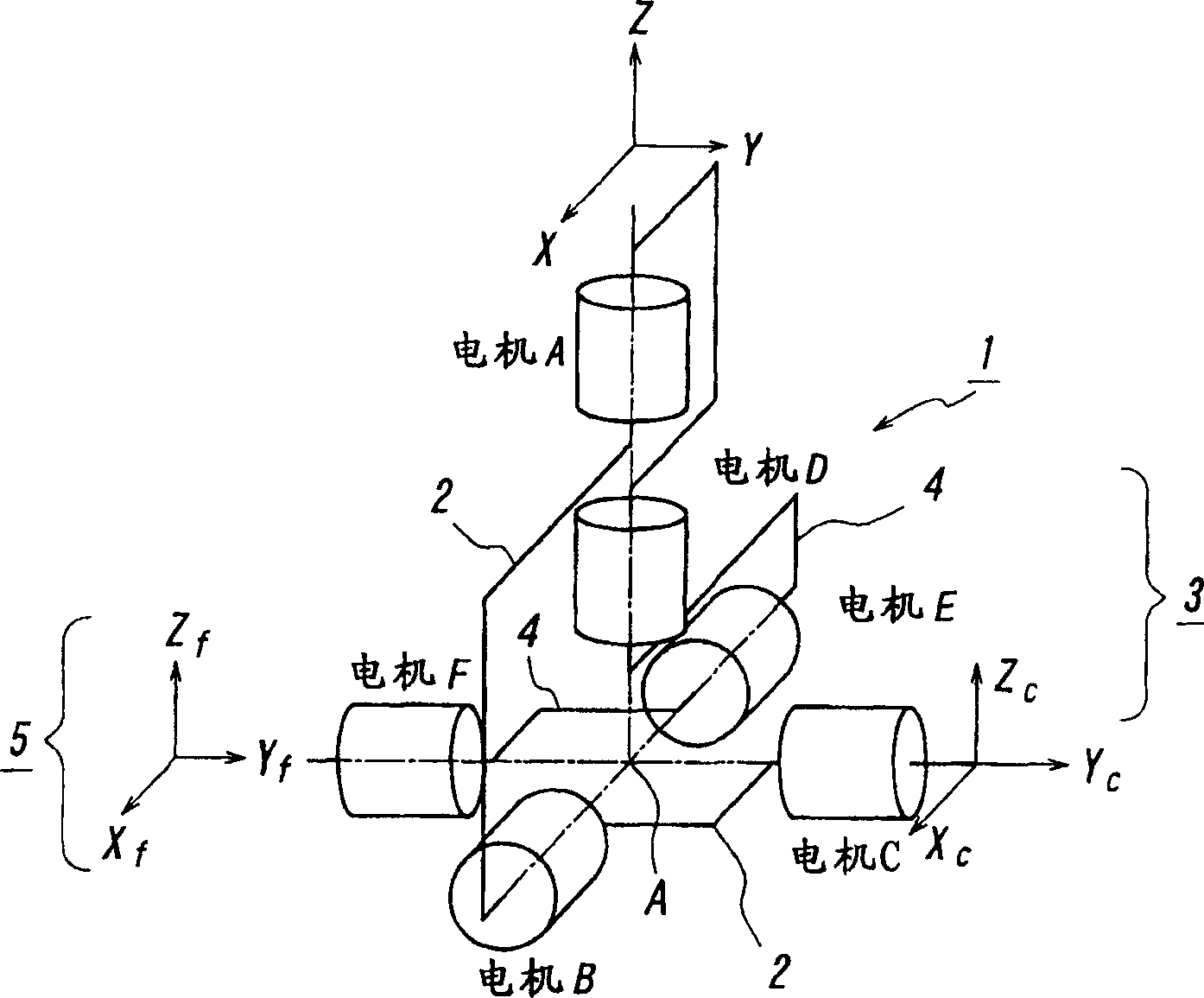

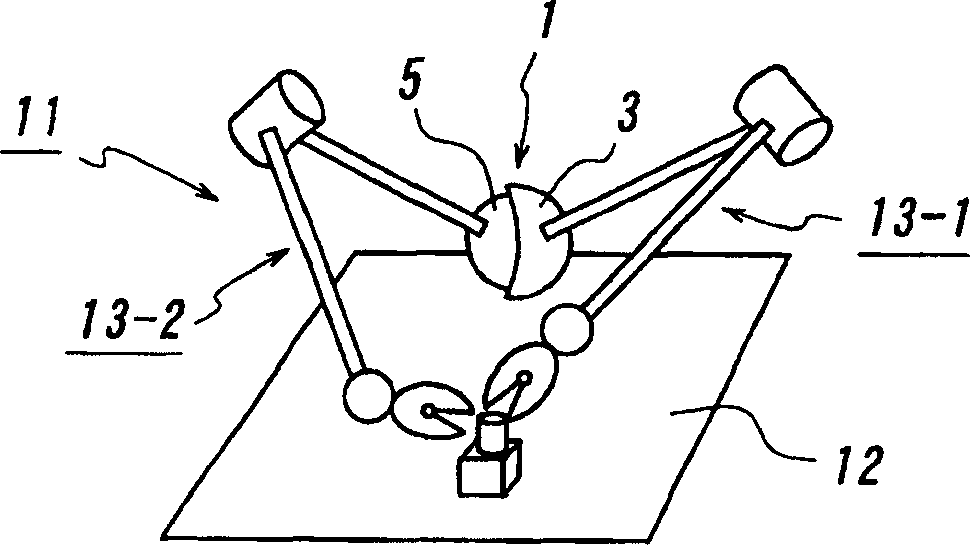

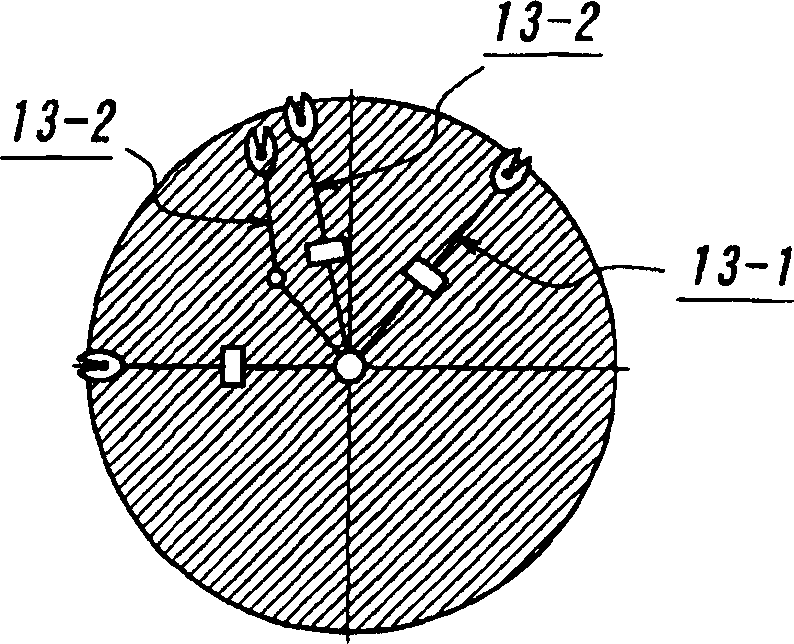

[0027] figure 1 It is a schematic diagram showing an embodiment of a double ball joint used in a double-arm shoulder joint mechanism and a double-leg hip joint mechanism according to the present invention. exist figure 1 In the illustrated embodiment, a double ball joint 1 comprises: a first ball joint 3 consisting of motors A, B and C used as actuators and a link used to connect the respective axes of rotation of said motors 2; and a second ball joint 5 consisting of motors D, E, and F used as actuators and a link 4 used to connect the respective rotating shafts of said motors. Also, in the double ball joint 1, the rotation centers of the first ball joint 3 and the second ball joint 5 are connected to a point A. As shown in FIG. In the above institutions, also in the Figure 8 In the mechanism shown, a coordinate system XcYcZc is established for motor C, and a coordinate system XfYfZf is established for motor F, which coordinate systems can express arbitrary postures ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com