Wedge shaped reaction tube in use for equipment of metal organic chemical vapor deposition

A metal-organic chemistry and vapor deposition technology, applied in the field of reaction tubes, can solve problems such as difficult to achieve, reduce pre-reaction, and uniform mixing of reaction gases, and achieve the effects of improving uniformity, reducing pre-reaction, and convenient sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

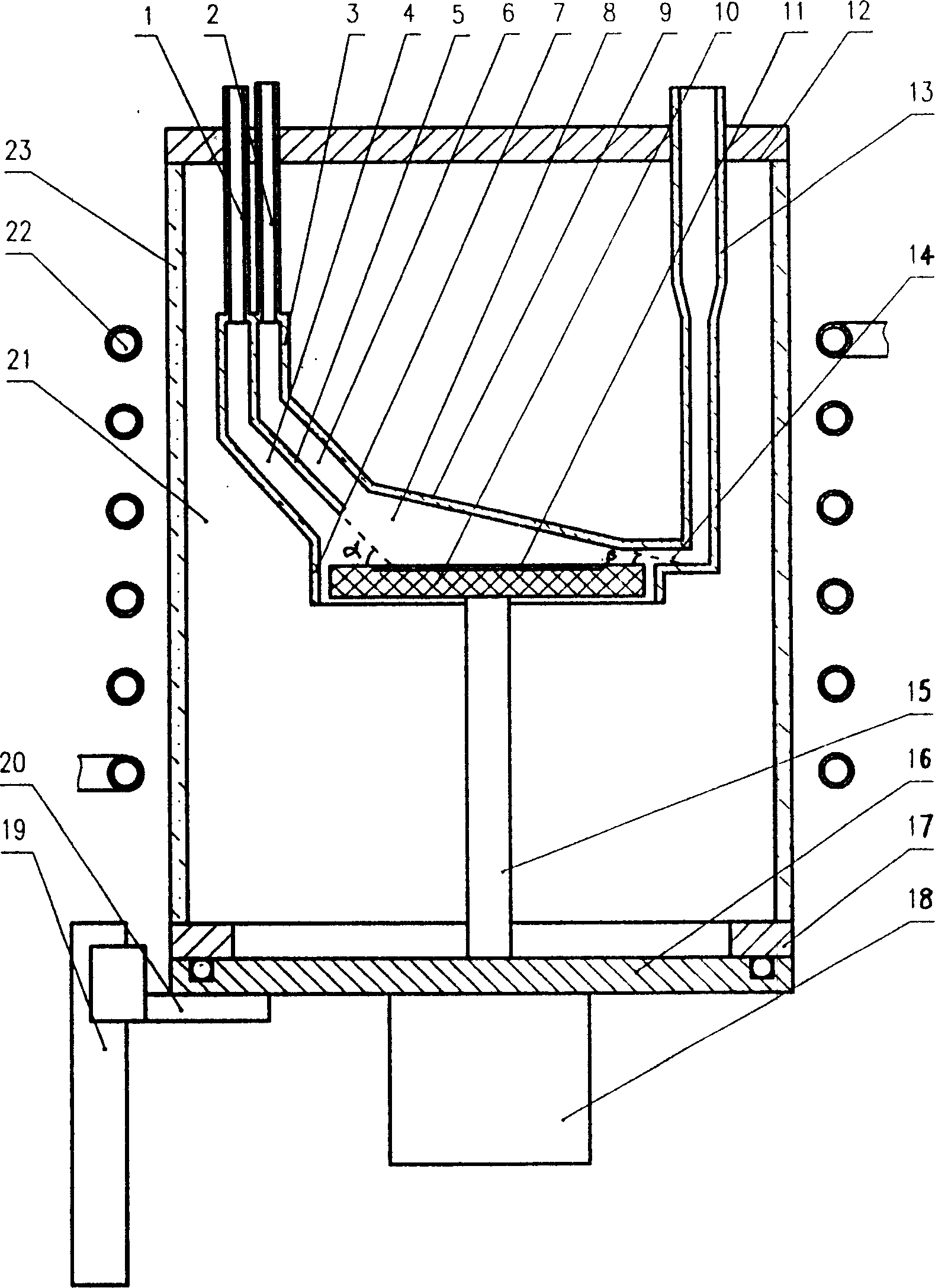

[0010] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0011] The present invention includes a quartz tube 23, an induction coil 22, a left air inlet pipe 1, a right air inlet pipe 2, an air outlet pipe 13, a substrate 11, a graphite boat 10, an upper flange 12, an annular lower flange 17 and a lower sealing plate 16 , the upper and lower ends of the quartz tube 23 are respectively the upper flange 12 and the lower flange 17 and are in sealing contact with the upper flange 12 and the lower flange 17, and there is a reaction between the upper flange 12, the lower flange 17 and the quartz tube 23 Chamber 21, the quartz tube 23 is covered with a cylindrical helical tubular induction coil 22 with cooling water in the middle, and the left inlet pipe 1, right inlet pipe 2 and outlet pipe 13 are installed on the upper flange 12, and are installed in the reaction chamber 21. There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com