Method for open-end rotor spinning

A technology of air spinning and spinning cup, which is applied in the direction of spinning machine, open end spinning machine, continuous winding spinning machine, etc. It can solve the problem of damage to yarn structure or fiber orientation and fiber draft, and limit air spinning Yarn application range and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

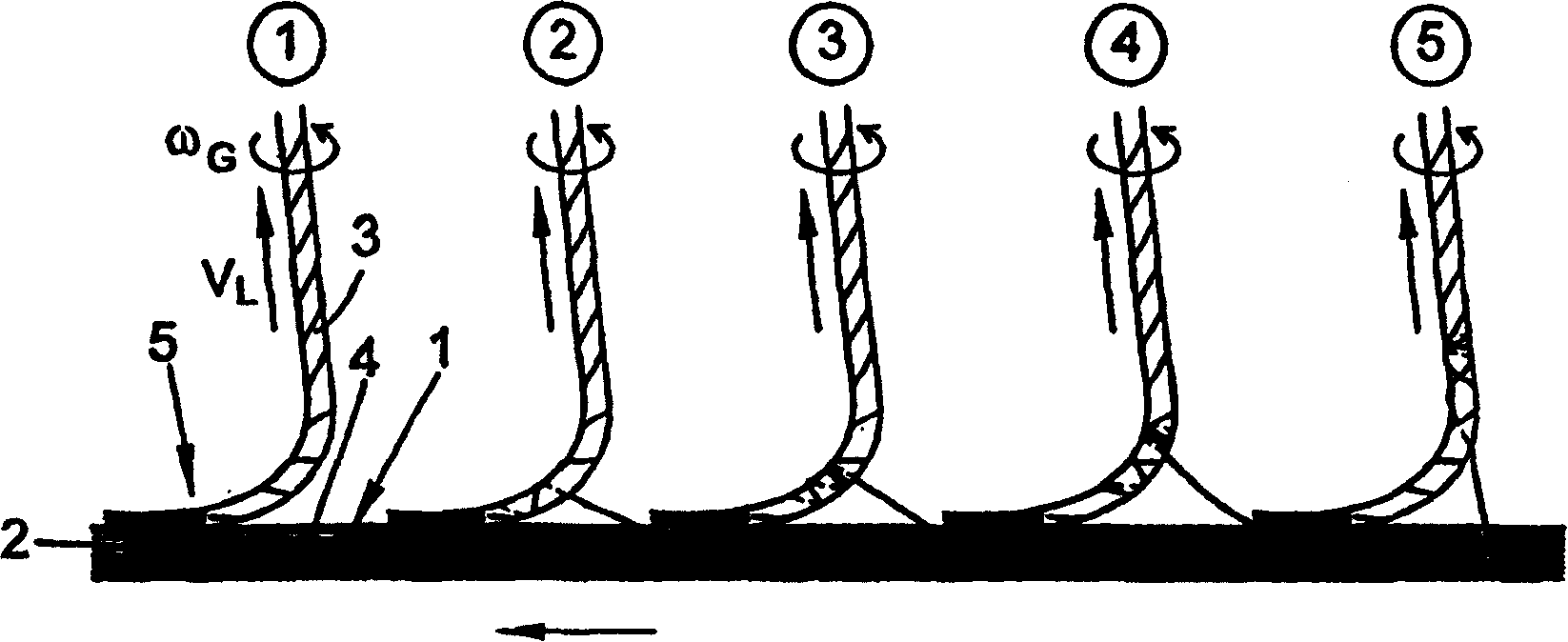

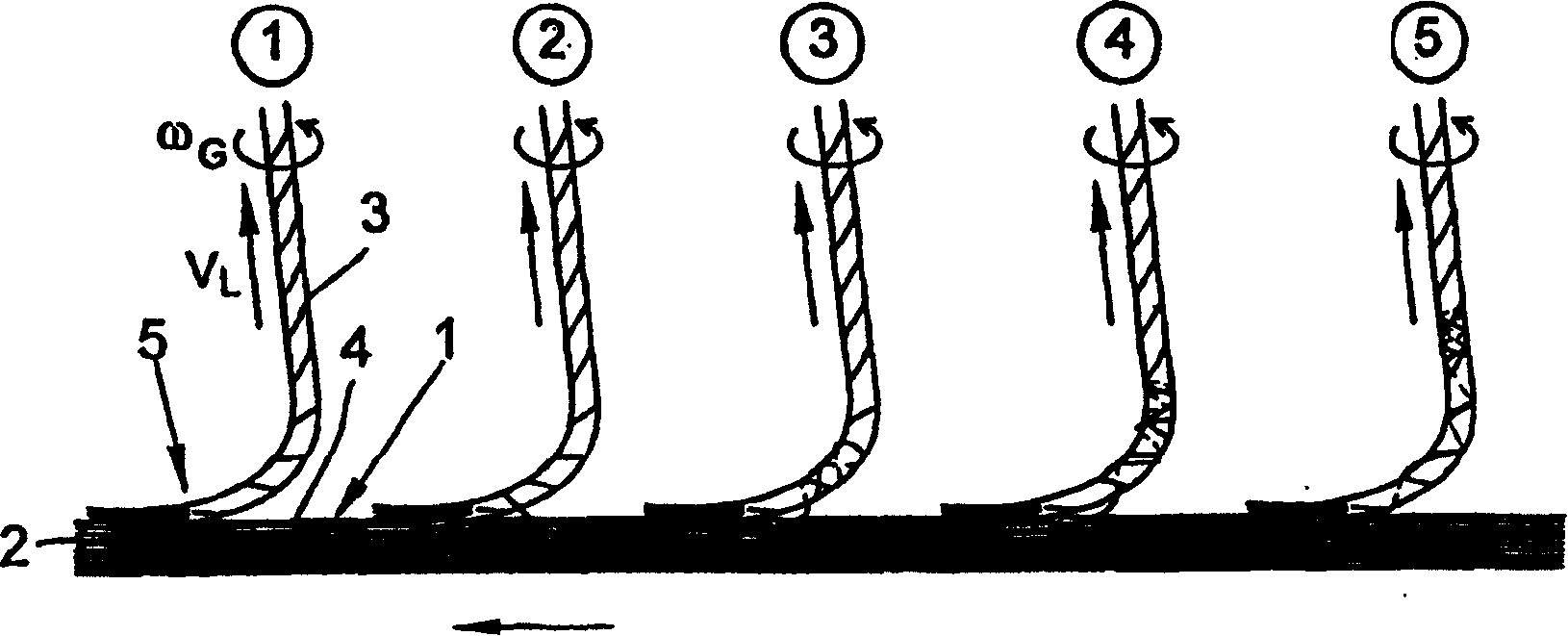

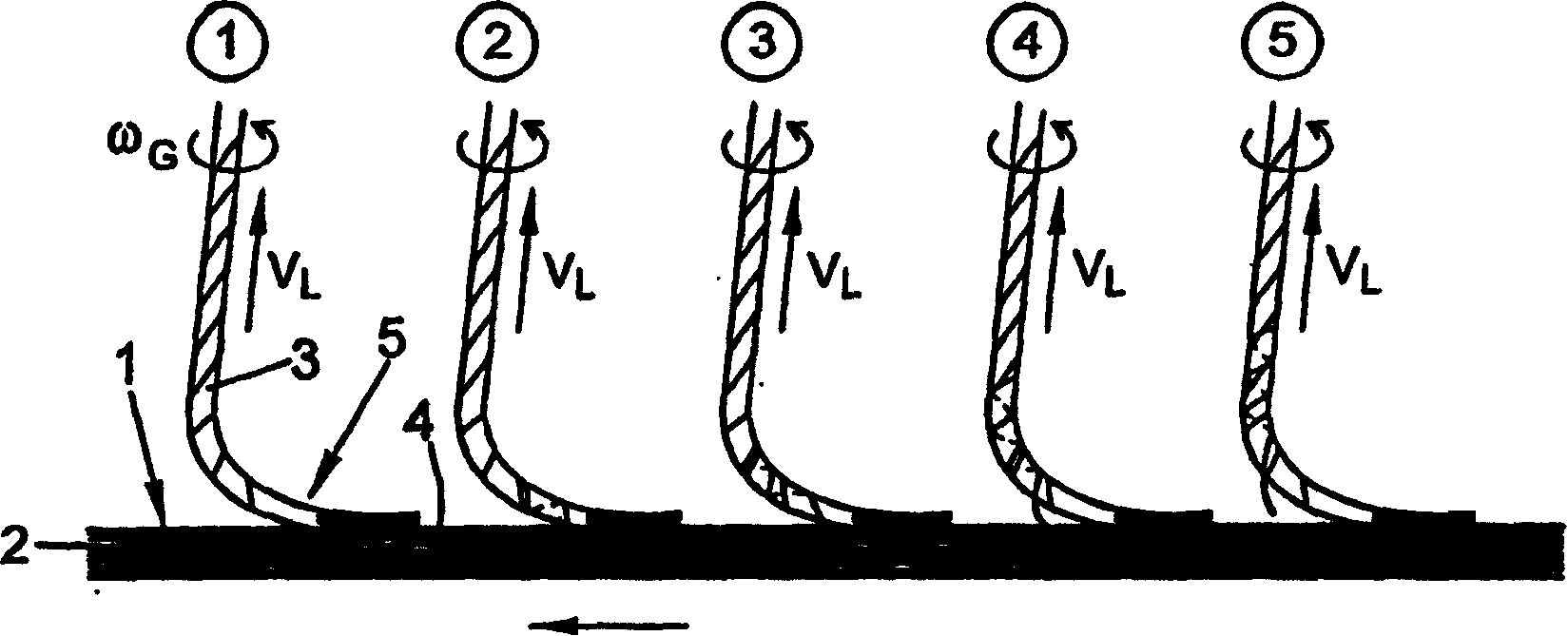

[0040] in Figure 1a , Shows the splicing stage of a single fiber 4 when spinning using the front access zone, that is, when the shank 3 is aligned with the spinning cup, and the single fiber 4 is caught by the yarn shank 3 at its front end. When entering zone 5, it reaches the rotor groove 1 from the fiber sliding surface 2 (the first stage). It can be clearly seen that in the yarn handle 3, the fiber turning direction is the Z twist direction. On the contrary, as can be seen in the second stage, the fiber 4 whose head is grasped is first wound around the outer layer of yarn in the S twist direction. As the doffing VL advances, the 4 ends of the fiber approach the point where other parts of the fiber are instantaneously wound around the outer layer of the yarn. In the fourth stage, the direction of the fiber 4 changes from S to Z, in which multiple concentrated turns may occur. Together, these loops bind the yarn and form so-called loops, which may interfere with subsequent proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com