Paper web honeycomb board

A honeycomb board and paper tube technology, applied in the field of board material processing, can solve the problems of limited cardboard thickness, poor cardboard strength uniformity, corrugated core honeycomb side length cannot be sufficiently small, etc., to achieve uniform strength and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

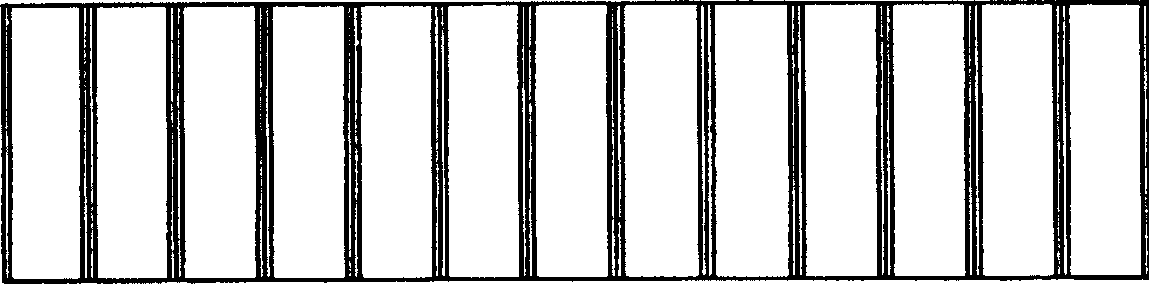

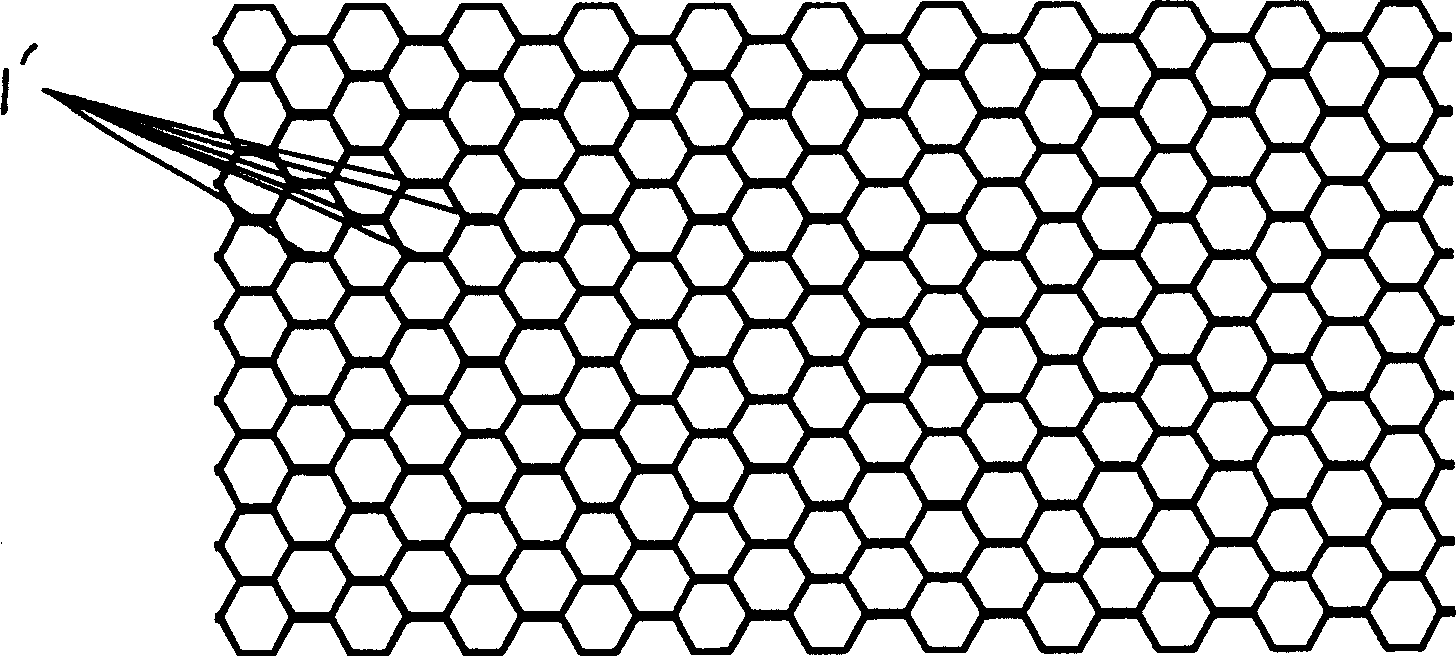

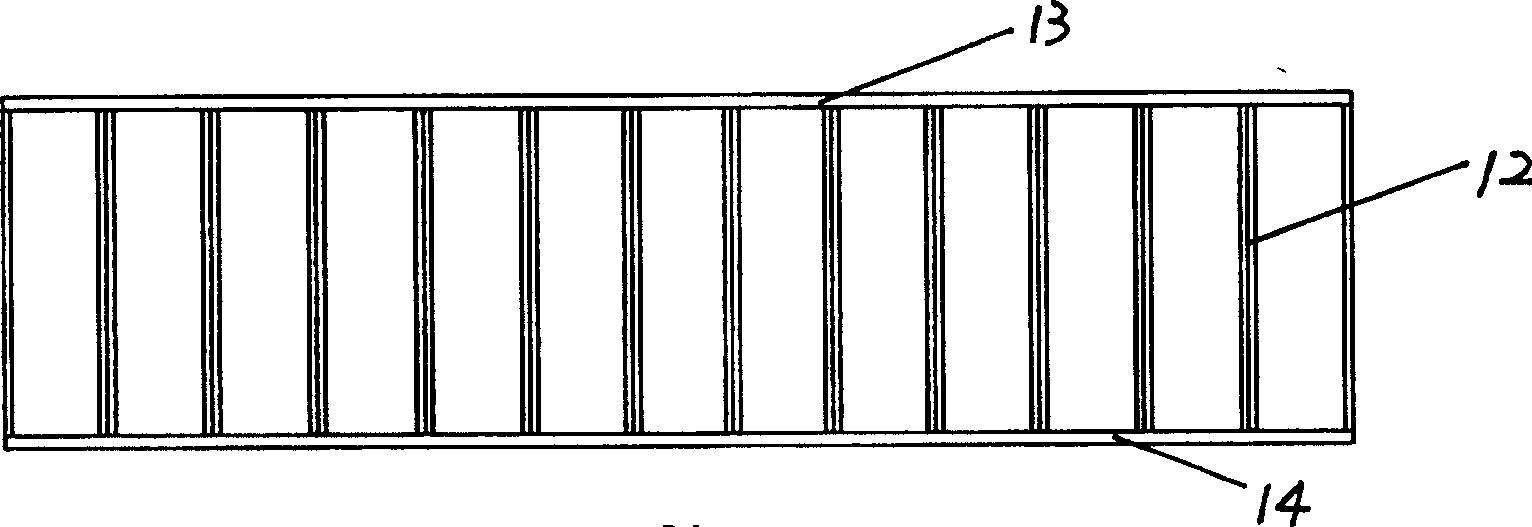

[0033] Embodiment one, see Figure 3 to Figure 5 Shown, a kind of paper tube honeycomb panel of the present invention, it comprises the paper tube 1 of several monomer structures, and paper tube 1 is a single layer, and paper tube 1 is formed by paper curling circle, and the paper tube 1 after curling makes The cross-section is circular, and the paper tube 1 after curling forms a glue bonding line 11 on its tube wall, and its glue bonding line 11 is a straight line formed along the axial direction; the length of each paper tube 1 is the same, and the The paper tubes 1 with the same length are arranged closely and orderly in the same direction and superimposed, and the superimposed parts are fixed by glue bonding phase to form the paper core 12, and the upper and lower end surfaces of the paper core 12 are respectively glued with the upper panel 13 , Bottom plate 14, promptly forms a paper tube honeycomb plate with the upper and lower end surfaces as planes.

Embodiment 2

[0034] Embodiment two, see Figure 6 Shown, a kind of paper tube honeycomb panel of the present invention, it comprises the paper tube 2 of several monomer structures, and paper tube 2 is single-layer, and paper tube 2 is formed by paper curling circle, and the paper tube 2 after curling makes Its cross section is circular, and the difference from Embodiment 1 is that the paper tube 2 after curling forms a glue bonding line 21 on its tube wall, and its glue bonding line 21 is a spiral line around the tube wall .

Embodiment 3

[0035] Embodiment 3, as shown in FIG. 7, a paper tube honeycomb panel of the present invention includes several paper tubes 3 with a single structure. The difference from Embodiment 1 is that the paper tube 3 is double-layered. The paper tube 3 is made up of paper curled twice. The paper tube 3 after curling makes the cross section circular. The paper tube 3 after curling forms a glue bonding line 31 on its tube wall. The glue bonding line 31 is A straight line formed along the axis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com