Sheet separating supplier and offset printer

A supply device and sheet material technology, applied to printing machines, general parts of printing machinery, printing, etc., to achieve the effects of simplifying device structure, preventing overlapping conveying, and simplifying control actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

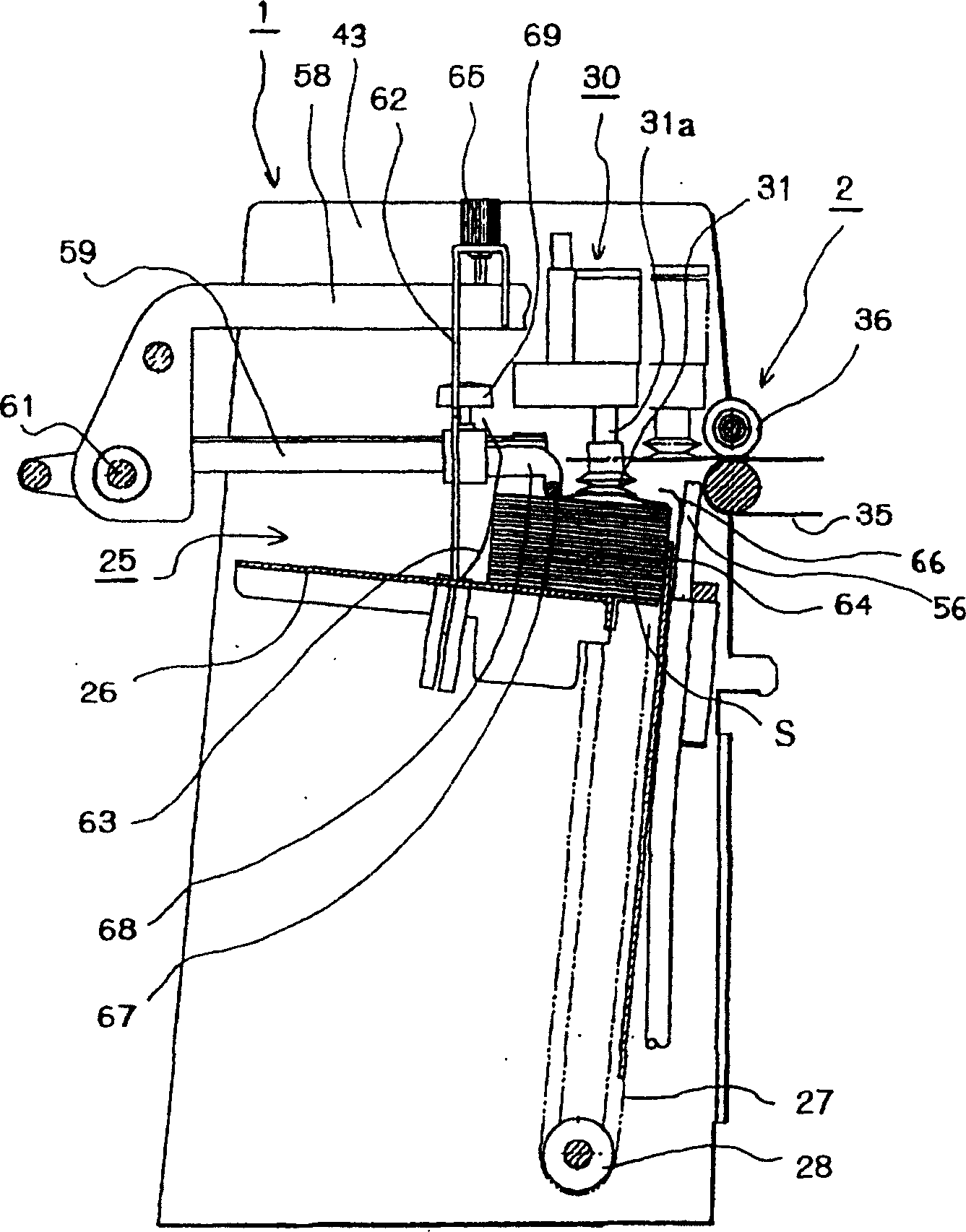

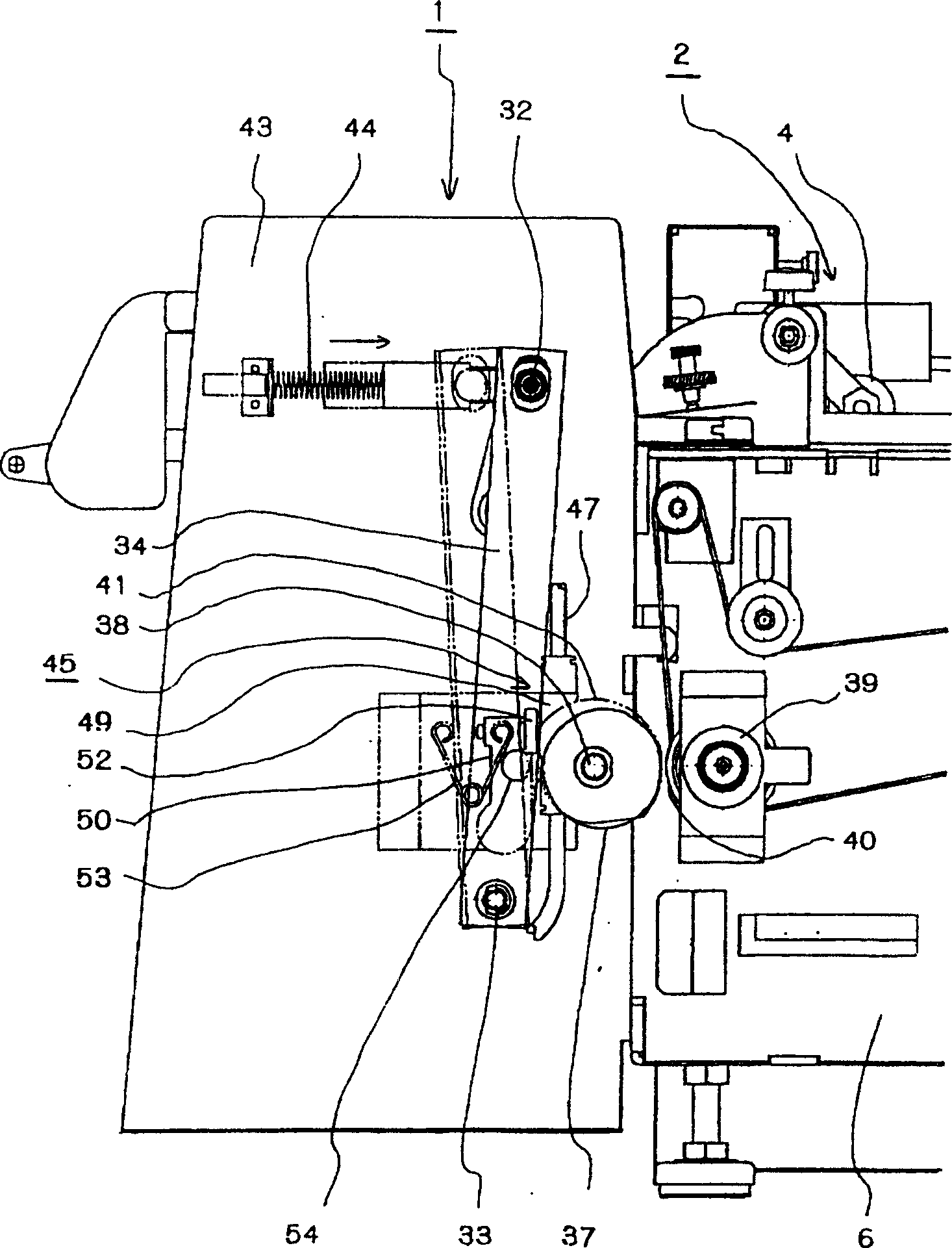

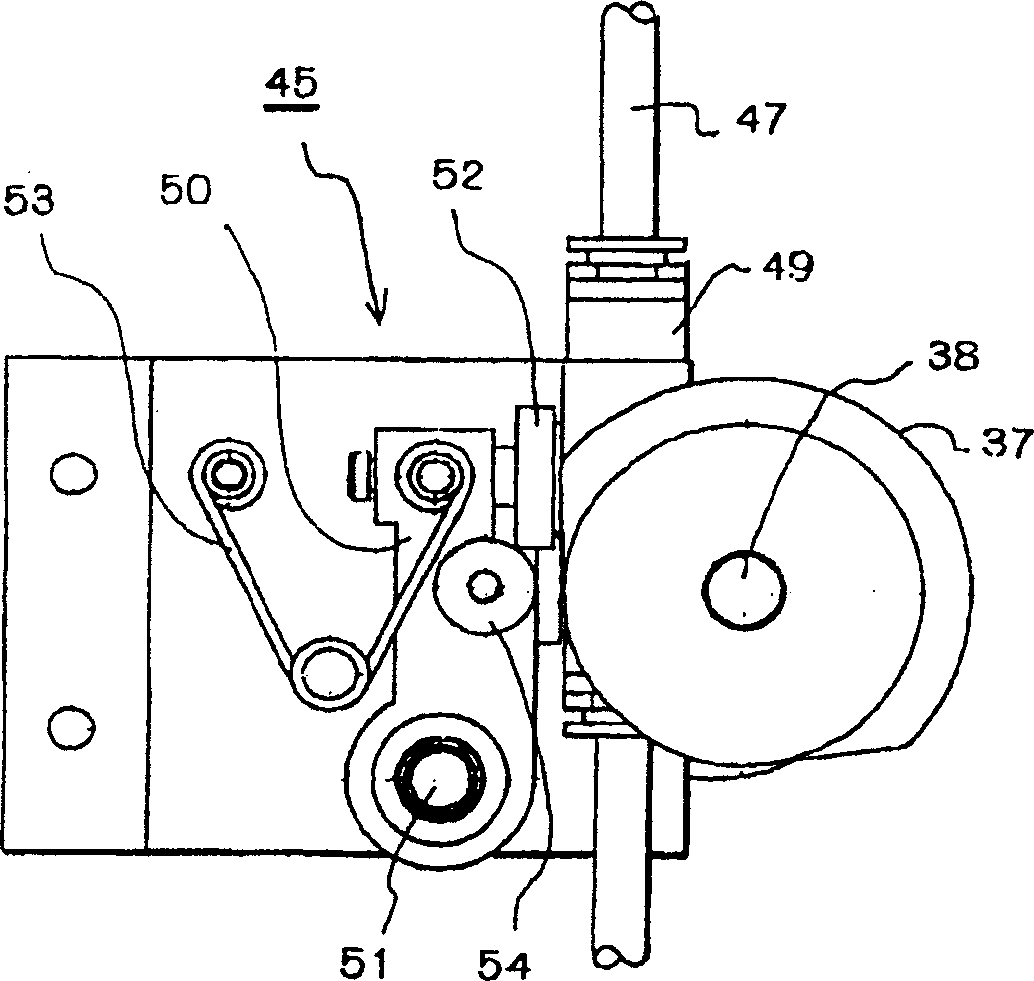

[0036] First, combined with Figure 8~ Figure 10 The structure of an offset printing machine will be described. In this embodiment, the type of printing unit is an offset printing machine that supplies water and ink separately.

[0037] In Figure 9 and Figure 10 Among them, the sheet separating and supplying device 1 separates sheets (such as business cards, cards, and envelopes, plastics, etc.) S stacked in the storage section one by one from the uppermost side, and supplies them. The sheet conveying device 2 feeds the separated sheet S to the printing unit 3 at a predetermined time. The sheet conveying device is provided with conveying claws (not shown) that abut against the rear end of the sheet S and feed the sheet into the printing section, and several pressure rollers 4 arranged in series along the conveying direction of the sheet S . The printing unit 3 can perform monochrome printing on the sheet S, and of course can also perform color printing. Using an image sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com