External protective pipe in directly buried pipeline system

A steam pipeline, Chinese and foreign technology, used in pipeline protection, protection of pipelines through thermal insulation, pipes/pipe joints/fittings, etc., can solve the problems of complex thermal insulation structure, failure of pipeline system life to meet expected requirements, and increased pipeline costs. To achieve the effect of convenient construction, simple method and lower total investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing

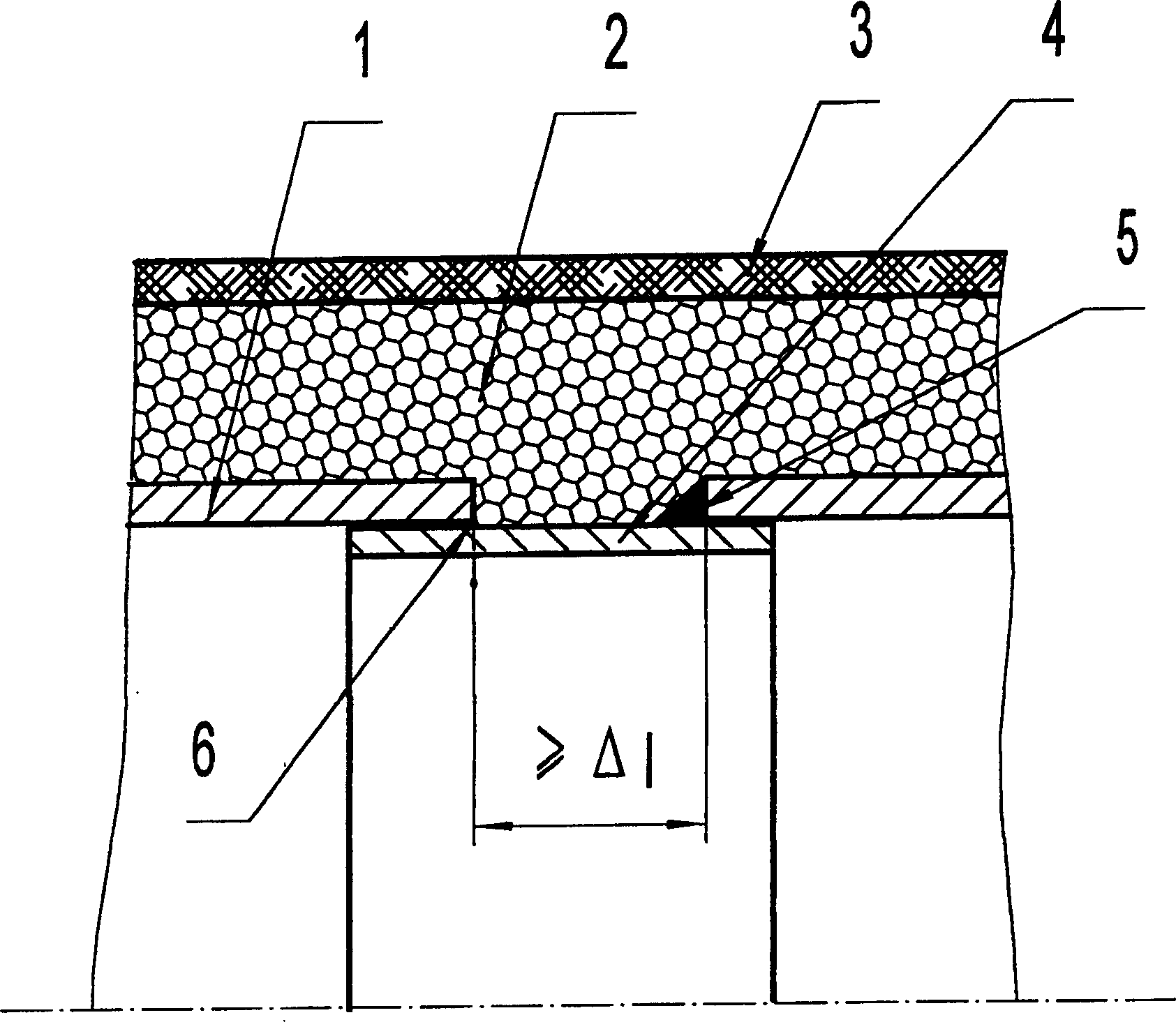

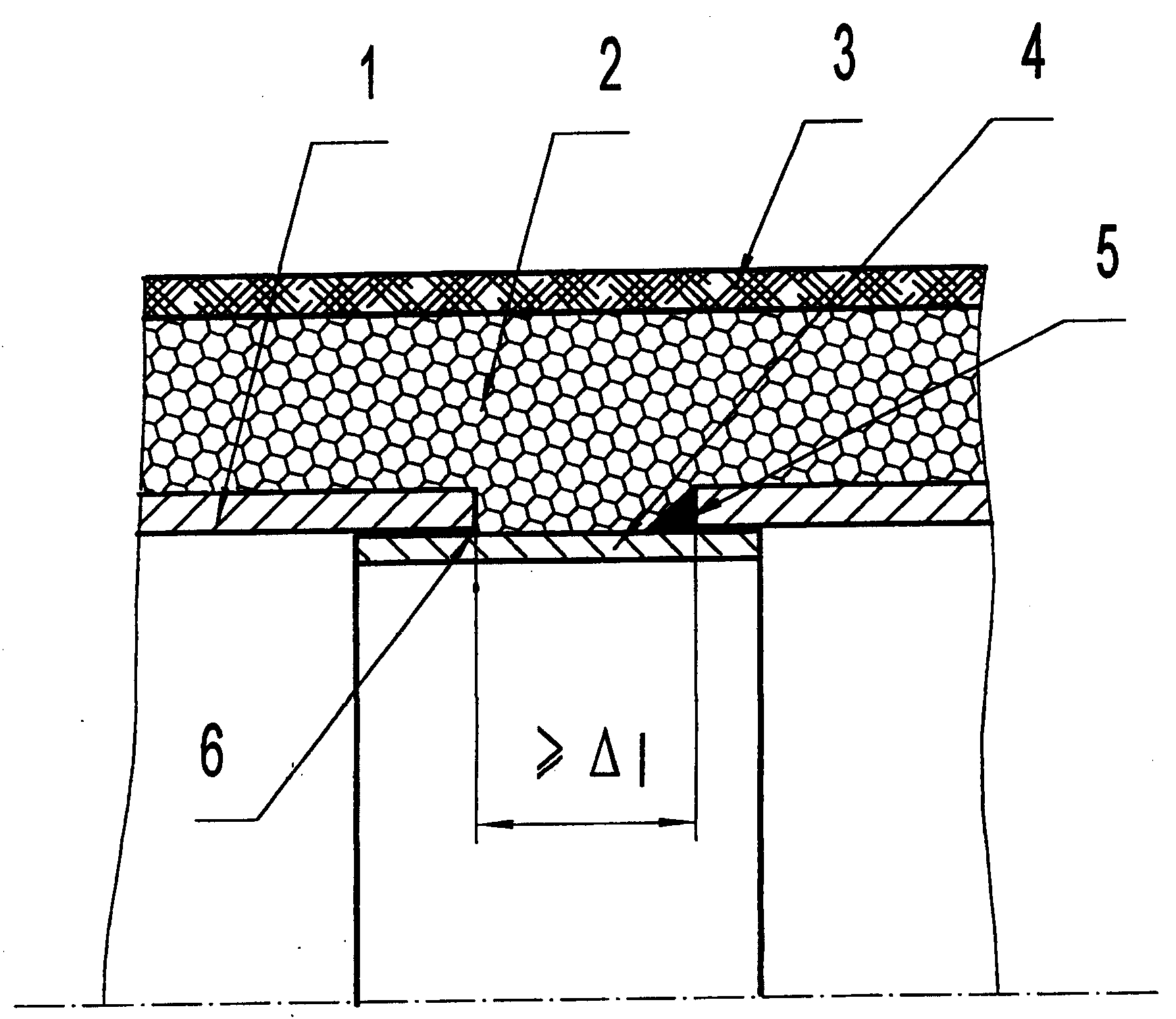

[0024] The composite outer protective pipe used for the directly buried thermal insulation steam pipeline in the present invention is made of figure 1 The inner steel conduit 1 shown in , the middle rigid polyurethane foam layer 2 and the outer layer 3 of fiber-wound reinforced thermosetting resin sanded glass fiber reinforced plastics are composed, and the said middle rigid polyurethane foam layer is realized by spraying . The outer surface of the steel conduit is completely isolated from the soil by the protective layer composed of fiber-wound reinforced thermosetting resin sand-filled FRP shell and sprayed rigid polyurethane foam, preventing corrosion of the outer surface of the steel conduit by various types of soil. The rigid catheter 1 is discontinuous and the width of the discontinuity is ≥ Δ1. In order to ensure the concentricity of the rigid catheter at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com