Grouping of film-like or sheet-like materials

A film-type and sheet-type technology, applied in the field of film-type or sheet-type material grouping and packaging devices, can solve the problems of reducing processing speed and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

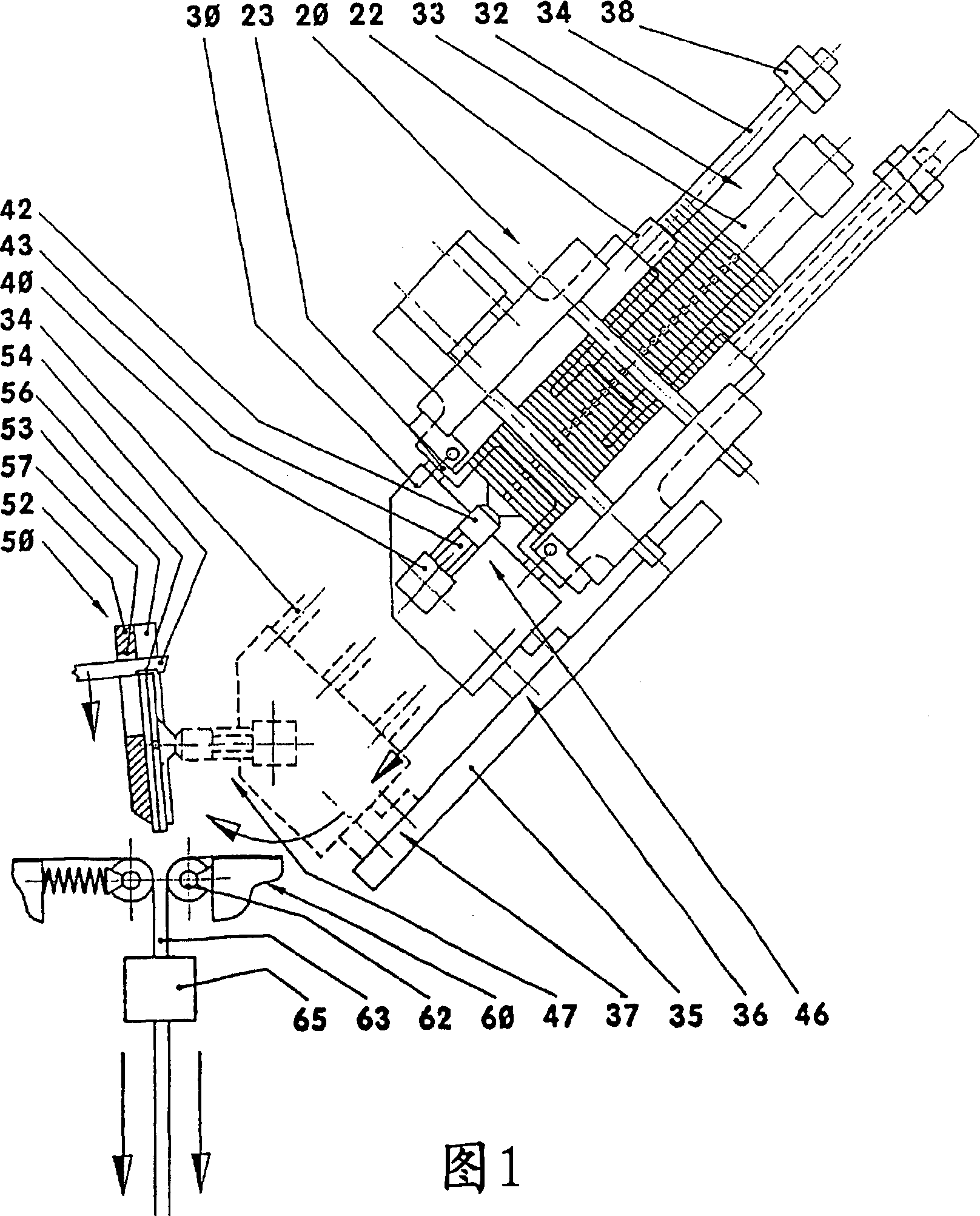

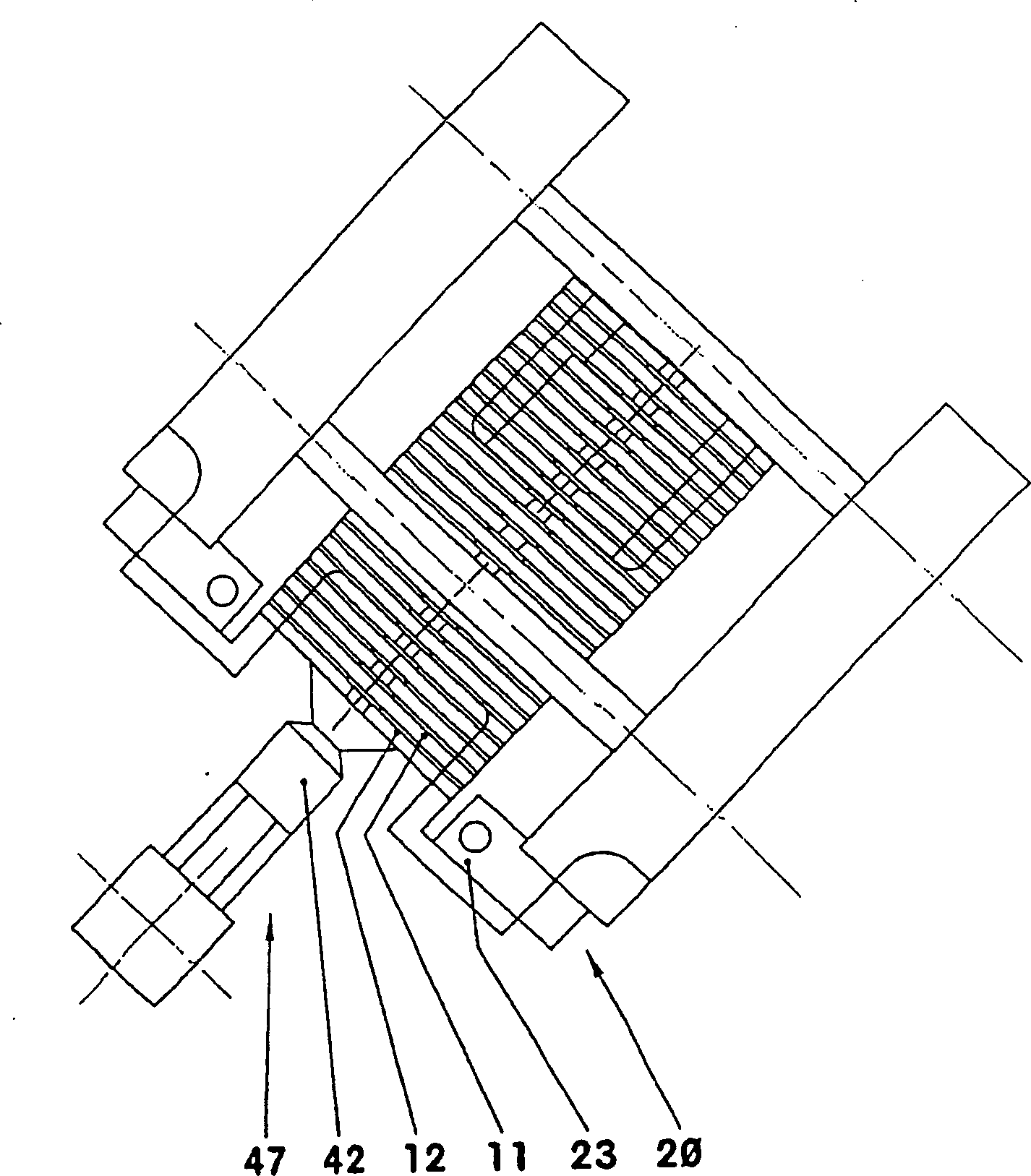

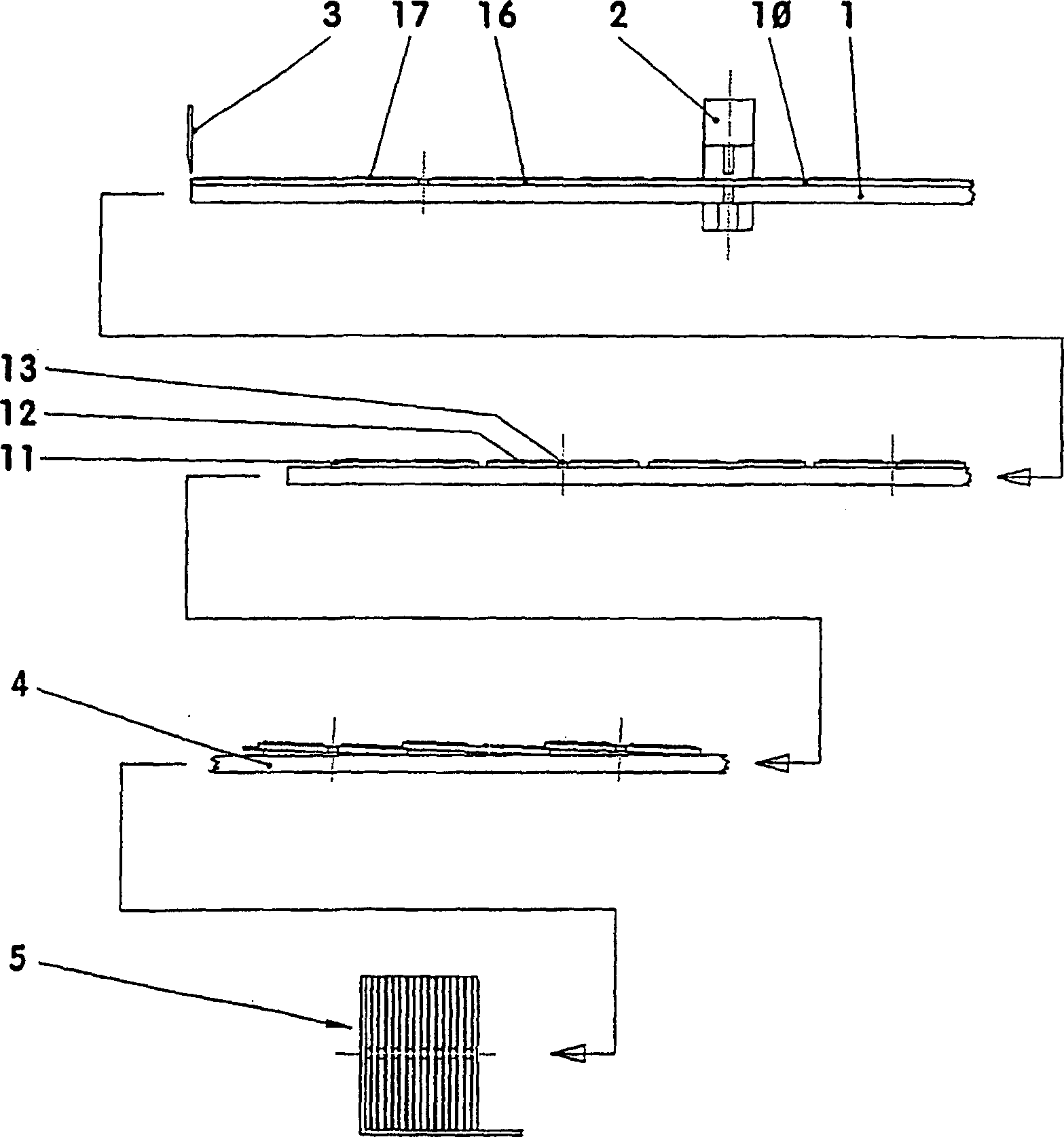

[0018] image 3 with 4 The group separation, processing and feeding of film or sheet material 11 , 12 to a chute 5 , 20 is shown. Since these materials are mostly multi-layered, they are referred to as composite material films 11, 12 hereinafter. A strip of composite material film 10 etc. is supplied to a punch 2 and a cutting device 3 by means of a conveying device 1 . At the cutting device 3 place, the composite material films 11, 12 are cut into generally equal-length individual composite material films 11, 12 by the composite material film strip 10, and they are overlapped and supplied to the sheet conveyor belt 4. The trough 5 or directly feeds the trough 20 shown in FIG. 1 .

[0019] The composite film strip 10 , for example an adhesive plaster strip, comprises, for example, a protective film 16 , an adhesive plaster carrier, for example, and a single-sidedly coated active substance carrier 17 , for example in the form of an adhesive plaster, adhering thereto. The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com