Supply and discharge method for supercharged fluid

A technology for pressurizing fluids, vents, used in connections with fluid cut-off devices, fluid pressure converters, transportation and packaging, etc., can solve problems such as pressure oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

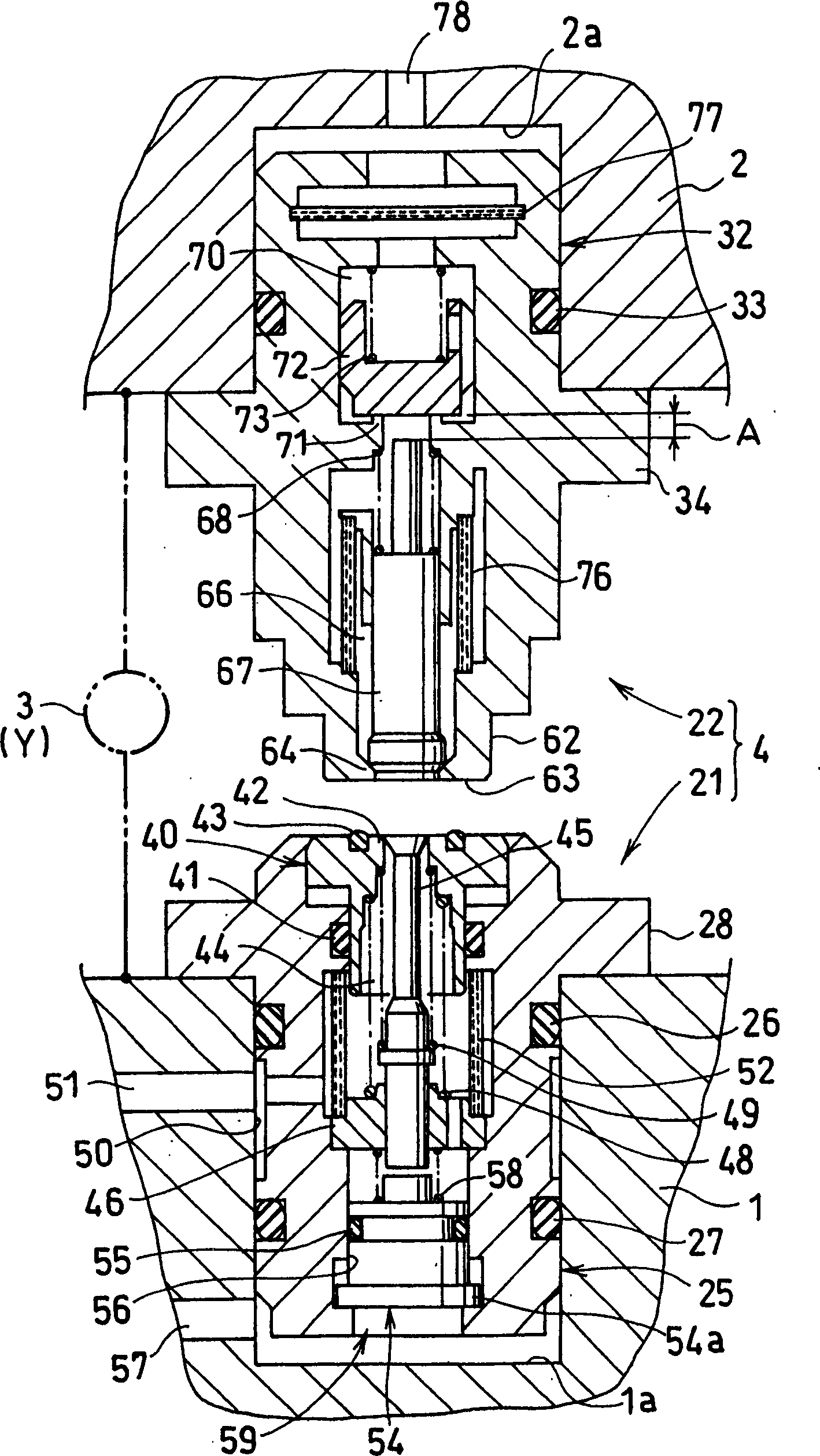

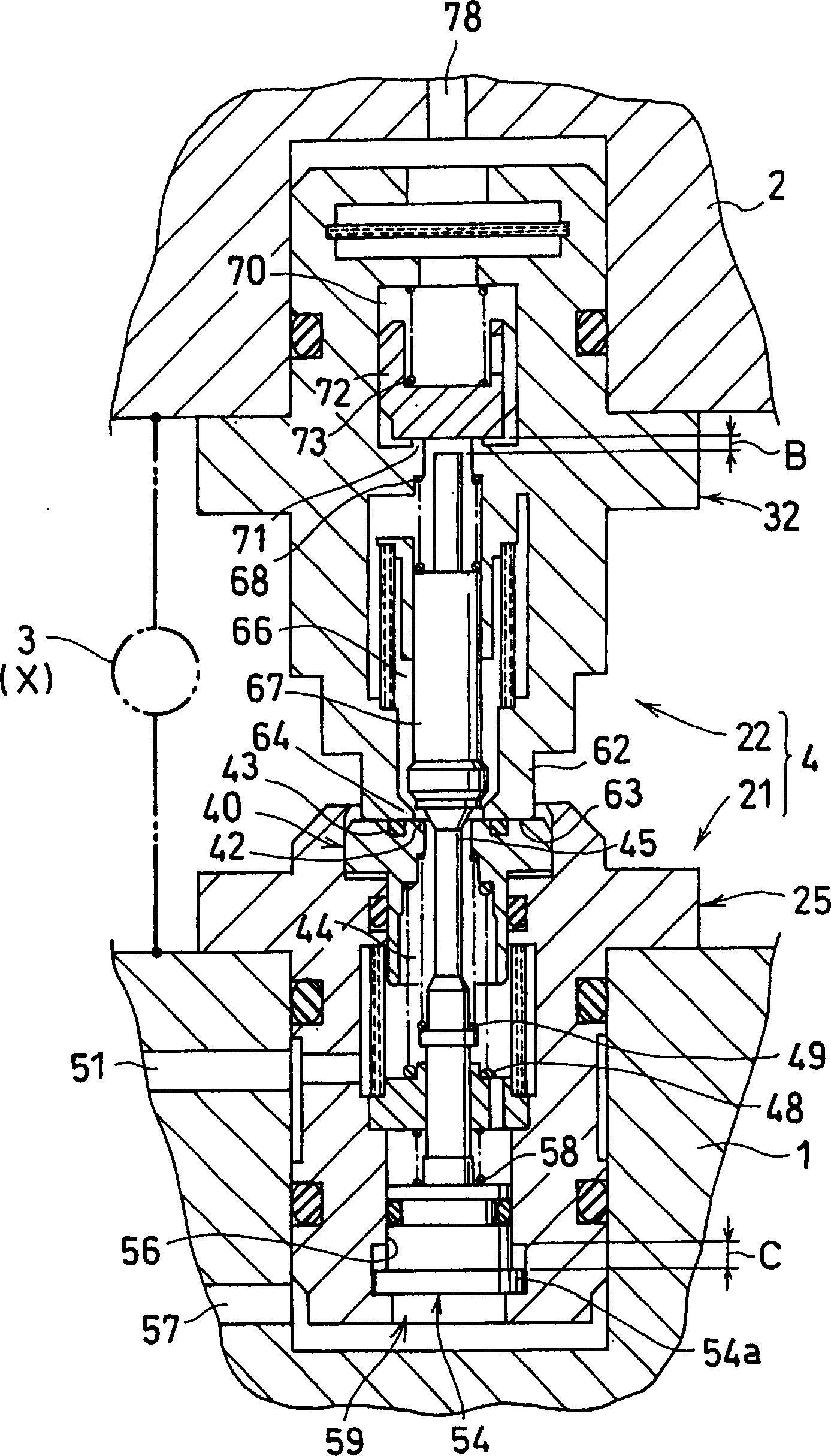

[0024] After this, an exemplary embodiment of the invention is described with reference to FIGS. 1 to 4 .

[0025] This embodiment exemplifies a case of the present invention, which is applicable to a method of supplying and discharging hydraulic oil between a workbench and a workbench of a machining center.

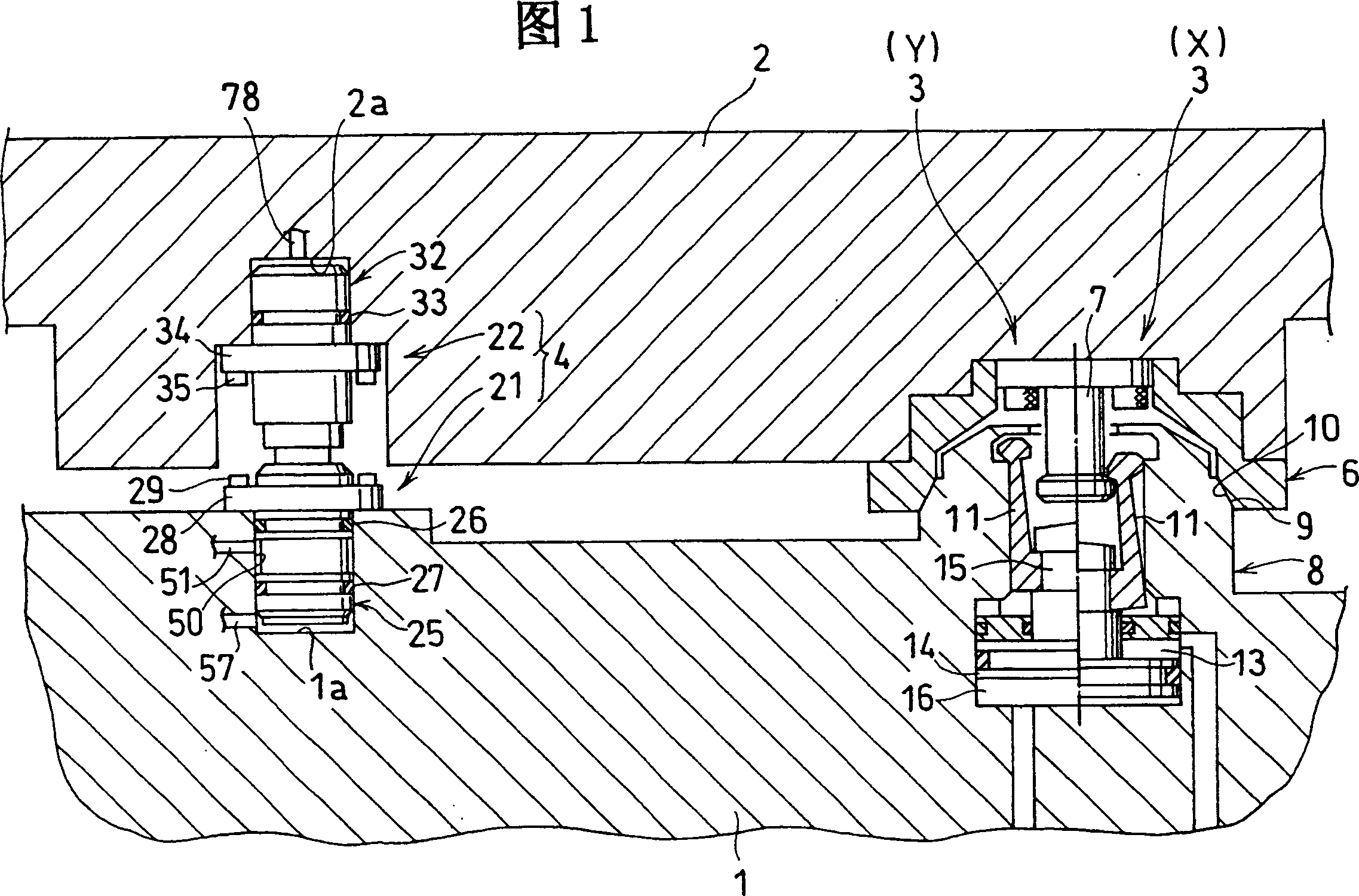

[0026] First, the entire structure of the supply and discharge device, which uses the above-mentioned supply and discharge method based on the schematic diagram of FIG. 1, will be described.

[0027] Multiple sets of locking devices 3 and multiple sets of quick couplers 4 are arranged on the workbench (first assembly) 1 and the working board frame (second assembly) 2 of the machining center. Here, hydraulic chucks and workpieces (both are not shown in the figure) are arranged on the upper surface of the working board frame 2 . And hydraulic oil is supplied to or discharged from the hydraulic chuck through the quick coupler 4, so that the workpiece can be fixed or releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com