Switching mechanism of protective switch

A switch mechanism and protection switch technology, applied in the direction of protection switch operation/release mechanism, etc., can solve the problem of the switch device becoming larger, and achieve the effect of reducing the total heat, ensuring the transition of small resistance, and reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Description of preferred embodiments

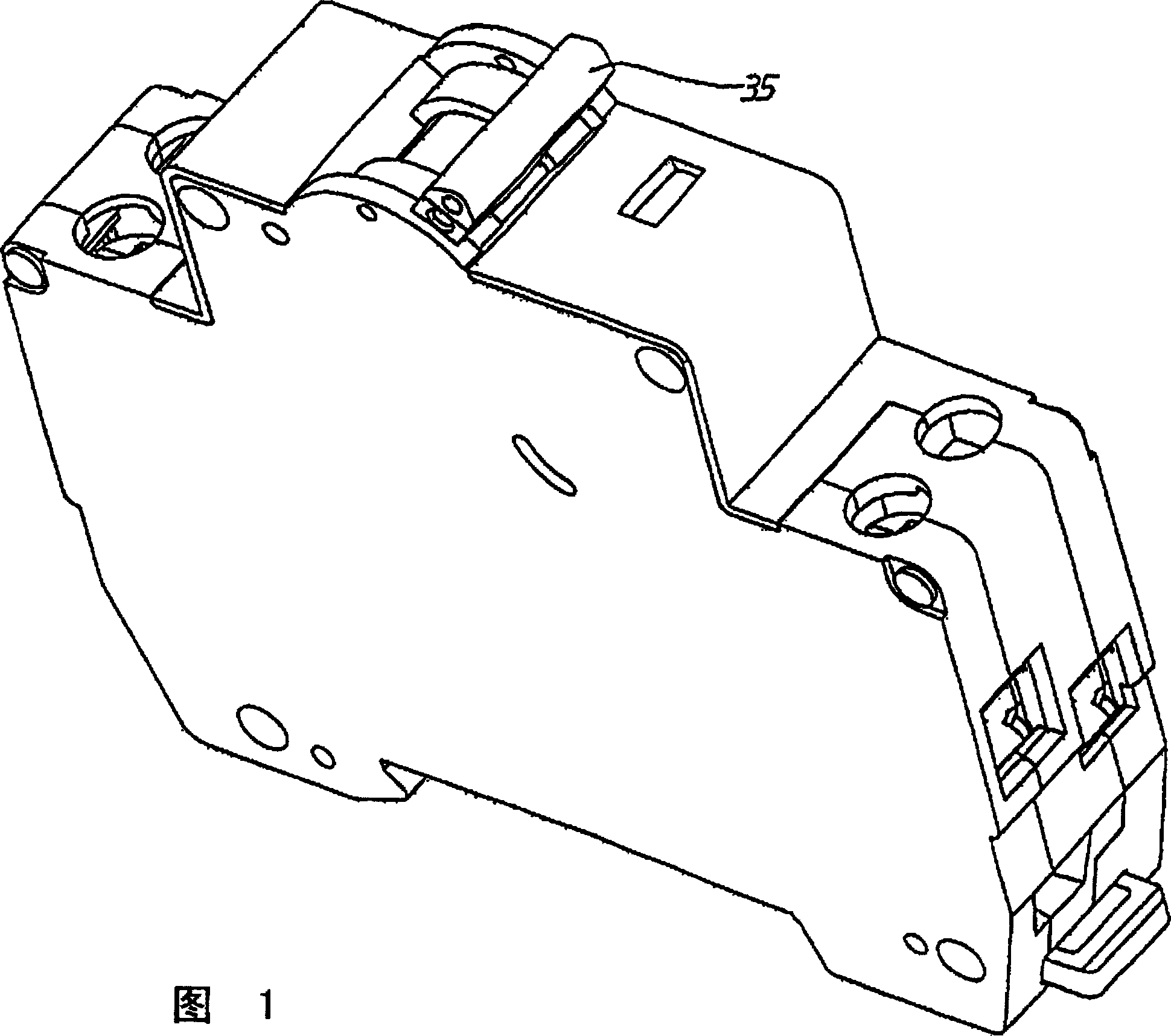

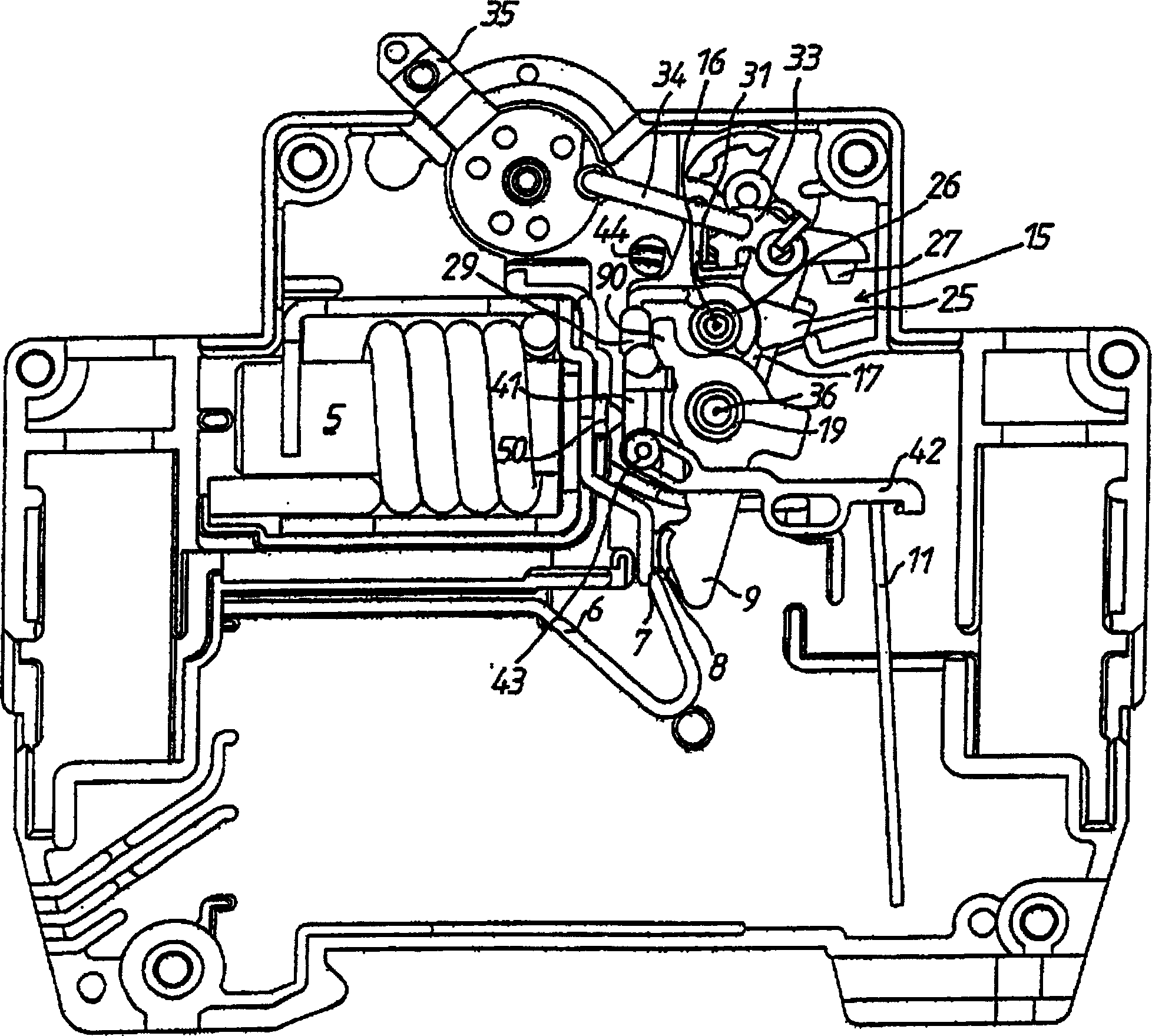

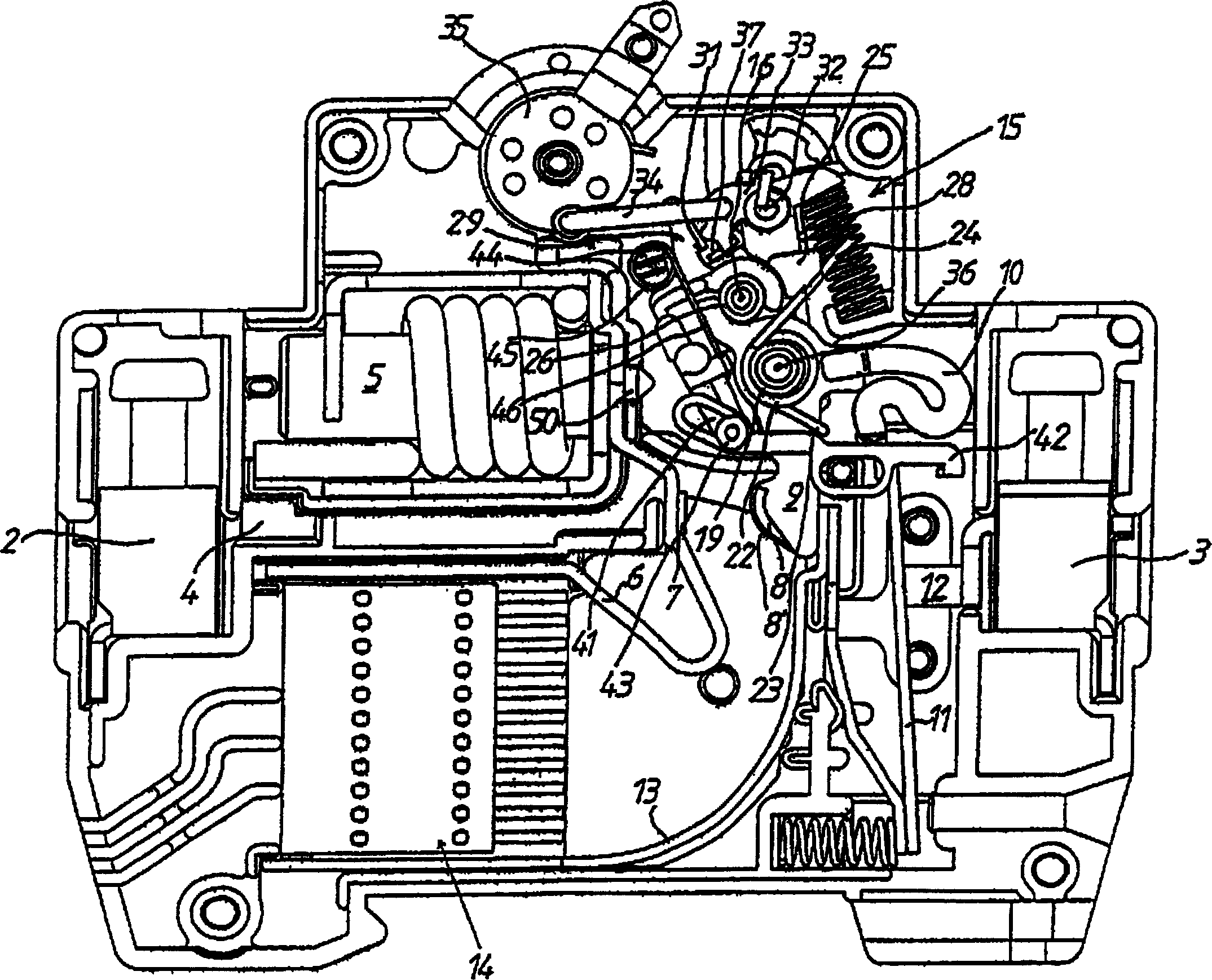

[0042] FIG. 1 shows the housing of a circuit breaker, which has two switching sections, namely a section for the phase conductor L of a single-phase AC circuit and a section for the associated neutral line N. In FIG. Each switching section consists of a terminal clamp 2 for the incoming conductor and a terminal clamp 3 for the outgoing conductor (see image 3 ). The first terminal clip 2 is connected to a current conductor bar 4 which is connected to a first coil end of a movable armature release 5 . The second coil end of the movable armature release 5 is connected to a further current conductor 6 which has a fixed contact 7 . The movable contact 8 which is in contact with the fixed contact in the switched-on state is fixed on the switching bridge 9 . The switch bridge 9 is connected to the free end of a bimetal 11 via a flexible conductive cable 10 . The second end of the bimetal strip 11 , which is held stationary relative t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap